Making an epoxy granite machine base

-

We used to be able to get "expired" stones basically for free until the church realized it could be a gold mine to sell them for a price just a wee bit lower than a new stone after adding the cost of updating the engraving ... so it was cheaper to buy an import surface plate than a old tombstone. (And ultimately a lot less work than to get three and lap them flat:)

-

I never thought of tombstones. Just countertops.

-

@smece said in Making an epoxy granite machine base:

.. they import ready-made tombstones from PRC and here they just engrave the names, pictures...

Subtractive tombstones are so old school.

-

@Danal said in Making an epoxy granite machine base:

I never thought of tombstones. Just countertops.

This gives a whole new meaning to the phrase "my printer just died"

-

Some time ago, I put an old printer on a wood-styrofoam-wood sandwich, which kinda worked, but I noticed that an old towel was also reducing vibrations well. Atm I just use furniture sliders..

I believe, this epoxy-concrete solution is overkill and I am sceptical about the benefit. The rubber dampeners only work if mass is (very) high and are known to resonate. My guess is that an old towel under the printer will vibrate less than the epoxy-solution.

-

Also, don't rule out regular concrete, the cement+water type. Many prefabs available, easy to cast in any desired shape if the desired shape is not available, and dirt cheap compared to epoxy concrete. 25 dollars/euros buys you a lot of concrete.

Very detailed shapes are possible with a bit of plasticizer and a finer aggregate mixture.The main disadvantage of cement-based concrete for machine tools is shrinking. After the standard 28 days most of the concrete has cured and most of the shrinkage has happened, but the concrete continues to shrink for decades. Not really an issue for a 3D printer though. But if I ever build myself a larger CNC lathe I better take that into account.

-

my family was making those countertops (artificial stone, it's some resin that comes in 50kg barrels and fillers that come in many different forms and sizes), it's cut with a regular tool (wood saw will go trough it no problem) nothing special about them but you cut openings for faucets etc .. there's no really "scrap" there as molds you use to make stuff are pretty good and efficient..

now, the huge granite/marble/heavy and hard base for milling I do understand (and use and...) but I'm not sure what would you get by using that as a base for printer ?! you need to stifen the printer as a whole, it can jump on the table it will not affect print quality if the printer is stiff ... the head "floats" above the print it's not like there's any force but inertia and that you won't solve with a heavy base ... if it's vibration/sound you are trying to solve, I keep all my printers on a special vibration dampening rubber feet made for washing machines and driers .. it reduce the sound a lot ... also filing the 4040 or 5050 profiles with sand reduces sound a lot (did not notice improvement on the print quality side) ... now, dunno how it all works for delta but I doubt it's much different

-

This is a video that CNC Kitchen did regarding vibrations and base. As usual he tried to take a quantitive approach.

-

FYI - mechanical engineer here

Resonance mode is proportional to mass, so increasing mass is a way to eliminate low-mode resonance (although not always effective). Dampeners (such as epoxy) don't eliminate the resonance energy much (~10%) but that would really only help you trying to limit energy / vibration into your stand (although some will reflect back up into the machine so it does still help).

In my opinion, the limiting factor of your design is the joint between your extrusion and your base plate. The mode of a plate with 80/20 extrusion as you have it is quite low. Increasing the thickness of your base mounting plate will increase your stiffness substantially (increasing your mode away from the motor resonance) as would adding some 90 degree stiffeners to your columns. Make sure you have a large amount of preload on the bolts as well - if you can find it, use a bolted joint calculator online to determine the bolt and the correct force to apply to it. Properly tightening the bolts can drive up stiffness as well.

Cross-beam supports would also substantially increase your stiffness (column to column). I'd advising putting them mid-span for greatest effectiveness, although it might be something of an eye-sore.

-

I have my printer on a fairly solid wooden end table. The printer has some dense closed cell foam for feet. There was still a bit of vibration, so I ended up taking a large weight and using nylon strapping to basically tie the printer down to the table by hanging the weight underneath the table. It looks pretty ghetto, but it worked wonders.

-

@TLAS Thank you for your insights, I will continue with the EG base and feet. After that I will evaluate and about reinforcing the joint between the extrusion and the base plate if needed.

I decided to make some test castings before doing to main job (duh I guess

). The test mold can house four pieces of 75x75x85mm with rounded corners and approximates the actual mold as much as possible.

). The test mold can house four pieces of 75x75x85mm with rounded corners and approximates the actual mold as much as possible.For the 1st batch I made 850g of EG with 10%w epoxy, 90%w fine white sand and 10g of blue dye.

-

wouldn't it be stronger with larger rocks? then again i think i read your

smallestlargest aggregate should be at most 1/3 of the smallest feature in your mold. -

@bearer said in Making an epoxy granite machine base:

wouldn't it be stronger with larger rocks? then again i think i read your

smallestlargest aggregate should be at most 1/3 of the smallest feature in your mold.Well technically my largest aggregate size is at most 1/3 of the smallest feature in the mold

But as I said I will do some experimenting with the materials that I already have and I'll go from there.

But as I said I will do some experimenting with the materials that I already have and I'll go from there. -

Apropos vibrations, here is an active way of dealing with them https://www.youtube.com/watch?v=HS7LvcBowCA

-

@zapta Ah yes, crazy deckingman

. Although it's semantics but I would not call the issue he was dealing with 'vibrations', more like movements. They seem quite low frequency and can be compensated for my a moving mass. This solution is whole lot less practical once you start going up the Hertzes

. Although it's semantics but I would not call the issue he was dealing with 'vibrations', more like movements. They seem quite low frequency and can be compensated for my a moving mass. This solution is whole lot less practical once you start going up the Hertzes

-

@zapta said in Making an epoxy granite machine base:

Apropos vibrations, here is an active way of dealing with them https://www.youtube.com/watch?v=HS7LvcBowCA

How would such a contraption be implemented on a delta.

-

@Phaedrux said in Making an epoxy granite machine base:

@zapta said in Making an epoxy granite machine base:

Apropos vibrations, here is an active way of dealing with them https://www.youtube.com/watch?v=HS7LvcBowCA

How would such a contraption be implemented on a delta.

I leave that to the experts and a separate thread haha

-

@Phaedrux said in Making an epoxy granite machine base:

How would such a contraption be implemented on a delta.

With another delta attached on top, turned upside down, and rotated 180degrees.

-

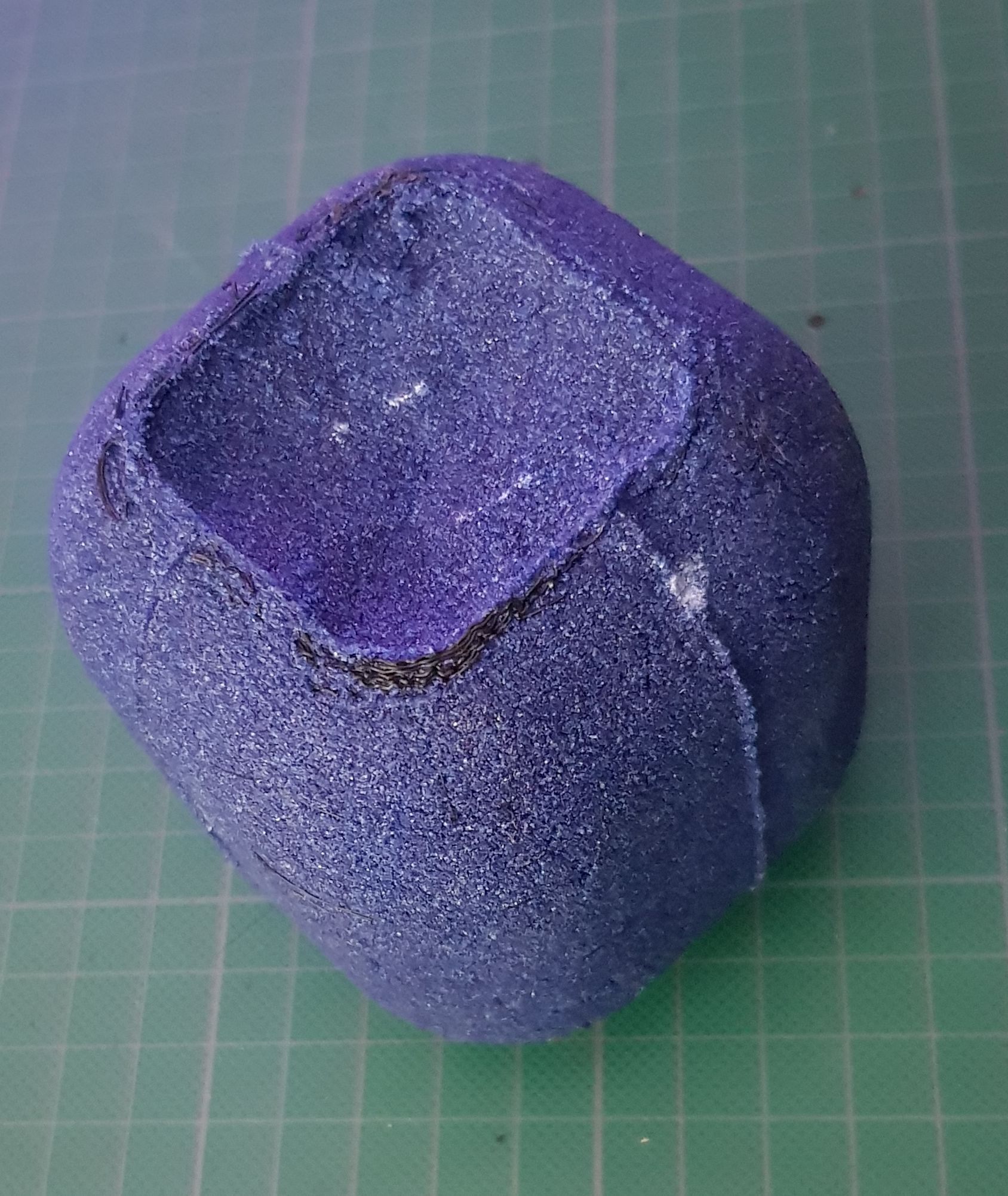

Here is a status update:

I just broke the 1st test piece out of it's mold. That in itself was definitely not easy, but not impossible (the mold only partially survived). For the 1st batch I made EG with 10%w epoxy, 90%w fine white sand and 10g of blue dye. The part in the picture weighs 638g on my scale and has a volume of 372cm^3 according to the cad model, resulting in a density of 1710kg/m^3 for those interested. I should note I only pressed the epoxy as hard as I could with my fingers, so no hammering (yet) and no vibration table.The part seems quite strong, and I have not been able to break or chip it whatsoever by hitting it as hard as I can with a light 200g hammer. I am very happy with how well the dye works. The store I bought it from does not specify what dye it actually is, but seeing how it's priced and what other dyes they offer, I believe it is an iron oxide.

While I believe it is doable to use this mixture, I would prefer a less porous result. Therefore I will be doing a 2nd and possibly 3rd test piece with 15%w and 20%w epoxy. I will keep this thread updated for those of you that follow here.

-

so the previous picture was just printed parts or?

if your main concern is the surface finish you could use an epoxy compatible gelcoat as a first layer before casting, or introduce even finer aggregate as well.