Help: Temp Sensors and Homing Issues

-

@94118 said in Help: Temp Sensors and Homing Issues:

I got my panel reflashed Successfully Still does not show reads from duet board

How is it connected?

-

Please post your homing files as well.

-

; homeall.g ; called to home all axes M98 Phomex.g; Calls to the file homex.g M98 Phomey.g; Calls to the file homey.g M98 Phomez.g; Calls to the file homez.g; homex.g ; called to home the X axis M913 X30; Set X motor current to 30% of its normal current to avoid ramming in case of crash G91; Switch to relative positioning G1 Z5 F300; Lower bed by 5[mm] in travel speed 5[mm/sec] to avoid crashing ; First pass (Corse movement) G91; Switch to relative positioning G1 X-295 F1200 S1; Move X axis to towards the endstop at travel speed of 25[mm/sec] (F1500) stop when endstop triggers (S1) G92 X0; Set X to home positions ; Go back a few mm G1 X5 F600; Move X axis by 5[mm] ; Second pass (Fine movement) G1 X-10 F300 S1; Move X axis to towards the endstop at travel speed of 6[mm/sec] (F360) stop when endstop triggers (S1) G92 X0; Set X to home position G90; Switch to absolute positioning M913 X100; Reset X motor current to normal current; homey.g ; called to home the Y axis M913 Y40; Set Y motor current to 40% of its normal current, to avoid ramming in case of crash ; First pass (Coarse movement) G91; Switch to relative positioning G1 Y-165 F1200 S1; Move Y-axis to towards the endstop, at travel speed of 20[mm/sec] (F1200), stop when endstop triggers (S1) G92 Y0; Set current Y-axis position to home position G1 Y5 F600; Move back Y-axis by 5[mm] ; Second pass (Fine movement) G1 Y-8 F300 S1; Move Y-axis to towards the endstop, at travel speed of 6[mm/sec] (F360), stop when endstop triggers (S1) G92 Y0; Set Y position to home position G90; Switch to absolute positioning M913 Y100; Reset Y motor current to normal current 100%; homez.g ; called to home the Z axis ; Prepare for Z-axis homing M913 Z80; Set Z motor current to 80% of its normal current, to avoid ramming in case of crash G91; Switch to relative positioning G1 Z5 F300; Move bed 5[mm] down, at travel speed 5[mm/sec], to avoid nozzle crash in case the bed is above the nozzle G90; Switch to Absolute positioning G1 X120 Y70 F3000; Move carriage to bed center, at travel speed 50[mm/sec] ; Home Z-axis G91; Switch to relative positioning G1 Z-175 F240 S1; Raise bed all the way up, at travel speed 5[mm/sec], stop when hit the endstop (S1) G1 Z3 s1; Lower bed by 3[mm] G92 Z6; Set Z position G90; Switch to absolute positioning M913 Z100; Set Z motor current back to 100%https://drive.google.com/open?id=1DM7rDGNchCwpNt-39v5gZfGMFRHqOjn3

https://drive.google.com/open?id=1DLPIYKRbN8US3hoOfUVw61BeYE6xptRiAll Homing files plus Picts of Current setup and wiring

-

A couple notes.

You don't need to use G92 to set the axis position after homing. When the endstop is triggered during a homing move it will automatically set the position to either the axis minima or maxima as defined by M208. I suggest you remove the G92s from homex and homey. You can use them in homez if you wish.

For homing moves you're using S1, in recent firmware versions it's now recommended to use H1 instead.

Your homey.g is moving the axis to the negative, but your endstop position is defined in your config.g as being at the positive end.

M574 Y2. So confirm where your Y endstop is, and make sure your homing move direction is correct. Assuming that 0,0 is the front left corner, Y+ would move towards the back of the machine. and M574 Y2 would indicate that the endstop is also at the back of the machine. But your homing move is negative. If a negative move is moving towards the back of the machine, you'll need to change the motor rotation inM569 P1 S1to beM569 P1 S0.In your homez you have a Z move at the start to lift the head, but you don't have the H2/S2 switch to allow you to move an axis before the axis is homed. Then later in the file you have G1 Z3 S1 after the axis has already been homed, but now it's moving away from the endstop, so will never hit it.

-

Homing is still problematic:

https://drive.google.com/open?id=1DQIW6JYFjs98MKeYba2B8x68rQdA3NQP

https://drive.google.com/open?id=1DSTCgvE8K6eaykKuqAlEWPQI_KsIg7DNPanel still states (Not Connecting) When i got it New from 3d Printed Solid it was able to connect. i think it might be a baud speed issue i read in some posts that the panel tries to connect 203600 when it is supposed to be 57600.

-

2/20/2020, 9:00:45 AM: Connected to 192.168.0.133 2/20/2020, 9:01:04 AM: G28 X: Error: G0/G1: insufficient axes homed 2/20/2020, 9:01:57 AM: G28 Y: Error: Bad command: [/c] 2/20/2020, 9:02:04 AM: G28 Z: Error: G0/G1: insufficient axes homedThe G28 X and G28 Z error states that you're trying to move an axis before it's homed. I pointed out in my last post why that happens.

The G28 Y error indicates that you have a

[/c]somewhere in your file that shouldn't be there. Probably a copy and paste error.Please repost your homing files as they currently are.

-

Note this is Not my Config .g File: FFCP Profile for Duet from Guyaros:

config.g file:

[c]

; Configuration file for Duet WiFi (Firmware 1.20)

; Executed by the firmware on start-up

; Last updated: 29.12.2017 by Guyaros; General preferences

M111 S0; Debugging off

G21; Work in millimetres

G90; Set absolute coordinates

M83; Set relative extruder moves

M555 P1; Set firmware compatibility to look like RepRapFirmare

M575 P1 B57600 S1; Comms parameters for PanelDue; Network settings

M550 PGuyaros Creator Pro; Set printer name

M551 PYOURPASSWORD; Set printer password

M587 S"SAMPLEWIFISSID" I192.168.1.101 J192.168.1.1;

M552 P"SAMPLEWIFISSID" S1; Set network SSID (P) Enable WiFi (S1); Motors drivers

M569 P0 S0; Set (X) motor drive 0 (P0) (X) goes backward (S0)

M569 P1 S0; Set (Y) motor drive 1 (P1) goes backward (S0)

M569 P2 S1; Set (Z) motor drive 2 (P2) goes forward (S1)

M569 P3 S1; Set (E0) motor drive 3 (P3) goes forward (S1)M350 X16 Y16 Z16 E16 I1; Set microstepping to x16 step, Interpolation enabled (I1)

;M92 X93.718 Y93.718 Z400 E192.55; Set axis steps/mm

M92 X94.118 Y94.118 Z400 E192.55; Set axis steps/mm

M906 X700 Y700 Z400 E1200 I20; Set motor currents [mA] and motor idle factor in percent (20%)

M84 S10; Set idle timeout to 10[sec] (S10); Axis kinematics

M201 X560 Y560 Z250 E300; Set axis accelerations [mm/s^2]

M566 X840 Y840 Z840 E120; Set axis maximum instantaneous speed changes [mm/min]

M203 X4800 Y4800 Z720 E1200; Set axis maximum speeds [mm/min]; Axis size

M208 X0 Y0 Z-3 S1; Set axis minima

M208 X290 Y145 Z165 S0; Set axis maxima

M579 X1.001895478 Y1.004419446; Scale axis (Correction factors based on measurment of printed models); Endstops

M574 X1 S1; Set endstop configuration, X endstop at low end (X1), Active high (S1)

M574 Y1 S0; Set endstop configuration, Y endstop at low end, Active low (S0)

M574 Z1 S2; Set endstop configuration, Z Probe at low end; Z probe and Bed compensation

M558 P1 X0 Y0 Z1 F240 H1 T4800; Set Z probe type to IR probe (P1), and is used for homing Z axis (Z1), Feed rate 4[mm/sec] (F240), Dive height 1[mm] (H1), Travel speed between points 80[mm/sec] (T4800),

G31 X35 Y0 Z1.78 P500; Set the probe offset on x axis (X35), set z probe trigger height (Z1.78), set probe output value at trigger height (P500) (FlashForge Blue BuildTak)

M557 X60:255 Y8:128 S40; Set probing grid for Auto Bed Leveling using G29 command, X(min:max) Y(min:max) S(Spacing); Heaters & Thermistors

; Bed

M305 P0 T94573 B4230 R4700 L0 H0; Set thermistor + ADC parameters for heater 0 (P0)

M304 P430.7 I0.478 D452.2; Set Bed PID parameters

M307 H0 A242.2 C901.9 D1.5 S1.0; Set heating process parametersheater, Heater0 (H0), Gain (A242.2), time Constant (C901.9), Dead time (D1.5), maximum PWM 100% (S1.0)

M143 H0 S120; Set temperature limit for heater 0 (H0) to 120[deg] (S120)

; Extruder

M305 P1 T90000 B4085; Set thermistor and ADC parameters

M143 S255; Set maximum heater temperature to 255C

M307 H1 A306.6 C146 D6 S1.0; Set heating process parameters, Heater1 (H1),Gain (A), time constant (C), Dead time (D6), Max PWM 100% (S1.0); Fans

M106 P0 S0 I0 F250 H-1; Set fan 0 value, PWM signal inversion and frequency, Thermostatic control is turned off (Duet board fan)

M106 P1 S0 I0 F250 H1 T45 L1; Set fan 1 value, PWM signal inversion and frequency, Thermostatic control is turned on (Extruder0 Fan)

M106 P2 S0 I0 F250 H-1; Set fan 2 value, PWM signal inversion and frequency, Thermostatic control is turned off (Blower fan); Tools

M563 P0 D0 H1 F2; Define tool 0 (P0), uses Extruder 0(E0) (D0), uses Heater 1 (Actually Heater E0), uses Fan 2 (F2)

G10 P0 X0 Y0; Set tool 0 axis offsets

G10 P0 R0 S0; Set initial tool 0 active and standby temperatures to 0C

T0; Select first tool

[/c]I have noted some of the settings he has listed for his FFCP Below is my Files:

; homex.g

; called to home the X axisM913 X30; Set X motor current to 30% of its normal current to avoid ramming in case of crash

G91; Switch to relative positioning

G1 Z5 F300; Lower bed by 5[mm] in travel speed 5[mm/sec] to avoid crashing; First pass (Corse movement)

G91; Switch to relative positioning

G1 X-295 F1200 S1; Move X axis to towards the endstop at travel speed of 25[mm/sec] (F1500) stop when endstop triggers (S1)

G92 X0; Set X to home positions; Go back a few mm

G1 X5 F600; Move X axis by 5[mm]; Second pass (Fine movement)

G1 X-10 F300 S1; Move X axis to towards the endstop at travel speed of 6[mm/sec] (F360) stop when endstop triggers (S1)

G90; Switch to absolute positioningM913 X100; Reset X motor current to normal current

; homey.g

; called to home the Y axisM913 Y40; Set Y motor current to 40% of its normal current, to avoid ramming in case of crash

; First pass (Coarse movement)

G91; Switch to relative positioning

G1 Y165 F1200 h1; Move Y-axis to towards the endstop, at travel speed of 20[mm/sec] (F1200), stop when endstop triggers (h1)

G1 Y5 F600; Move back Y-axis by 5[mm]; Second pass (Fine movement)

G1 Y135 F300 h1; Move Y-axis to towards the endstop, at travel speed of 6[mm/sec] (F360), stop when endstop triggers (h1)

G90; Switch to absolute positioning

M913 Y100; Reset Y motor current to normal current 100%; homez.g

; called to home the Z axis; Prepare for Z-axis homing

M913 Z80; Set Z motor current to 80% of its normal current, to avoid ramming in case of crash

G91; Switch to relative positioning

G1 H2 S2 Z5 F300; Move bed 5[mm] down, at travel speed 5[mm/sec], to avoid nozzle crash in case the bed is above the nozzle

G90; Switch to Absolute positioning

G1 X120 Y70 F3000; Move carriage to bed center, at travel speed 50[mm/sec]

; Home Z-axis

G91; Switch to relative positioning

G1 Z-175 F240 S1; Raise bed all the way up, at travel speed 5[mm/sec], stop when hit the endstop (S1)

G92 Z6; Set Z position

G90; Switch to absolute positioning

M913 Z100; Set Z motor current back to 100% -

To encapsulate your gcode snippets in code blocks use the </> button in the reply dialogue. I think that's where your [/c] came from.

-

(or if you want to type use ``` as pr the markdown standard as bbcode isn't supported)

-

@94118 said in Help: Temp Sensors and Homing Issues:

M575 P1 B57600 S1; Comms parameters for PanelDue

If you remove this line entirely it will use the defaults which should work with the paneldue. What baud rate do you have selected on the paneldue settings screen?

M587 S"SAMPLEWIFISSID" I192.168.1.101 J192.168.1.1;

M552 P"SAMPLEWIFISSID" S1; Set network SSID (P) Enable WiFi (S1)You should remove that from the config.g. Send it one to enter the SSID and password and that's all you need to do. The config.g should only have M552 S1 to enable the wifi module at bootup. That's it.

M579 X1.001895478 Y1.004419446; Scale axis (Correction factors based on measurment of printed models)

if this is a config.g from someone else you probably don't want to use their scale factor.

; Z probe and Bed compensation

M558 P1 X0 Y0 Z1 F240 H1 T4800; Set Z probe type to IR probe (P1), and is used for homing Z axis (Z1), Feed rate 4[mm/sec] (F240), Dive height 1[mm] (H1), Travel speed between points 80[mm/sec] (T4800),

G31 X35 Y0 Z1.78 P500; Set the probe offset on x axis (X35), set z probe trigger height (Z1.78), set probe output value at trigger height (P500) (FlashForge Blue BuildTak)

M557 X60:255 Y8:128 S40; Set probing grid for Auto Bed Leveling using G29 command, X(min:max) Y(min:max) S(Spacing)The config is setup to use a Z probe, but your homez is setup to use an endstop switch. Do you have a probe?

; homex.g ; called to home the X axis M913 X30; Set X motor current to 30% of its normal current to avoid ramming in case of crash G91; Switch to relative positioning G1 Z5 F300; Lower bed by 5[mm] in travel speed 5[mm/sec] to avoid crashingThat

G1 Z5 F300should beG1 Z5 F300 H2. That will get rid of the insufficient axis error for homex.I strongly suggest that you use the web configurator tool to create a new config file set. Use the details you know about the printer to fill out the form.

https://configtool.reprapfirmware.org/StartThen you can make changes to that if needed. Compare it to the other config.g and try to understand what's different between them.

-

As i have stated the config.g file is not mine!!!

-

Then why bother posting it?

-

Have tried changes here is the result of test:

-

Have also tried the previous version RRF that caused my thermistors to not read stating N/A

-

It looks like you're using the test macros that came on the SD card. Do not use those. They are meant for factory testing only.

-

Homing controls result Minimal movement had to maunally home axis numbers are X 216, Y 103, Z 145 these number i had to manually move so that my head is in back right corner.

-

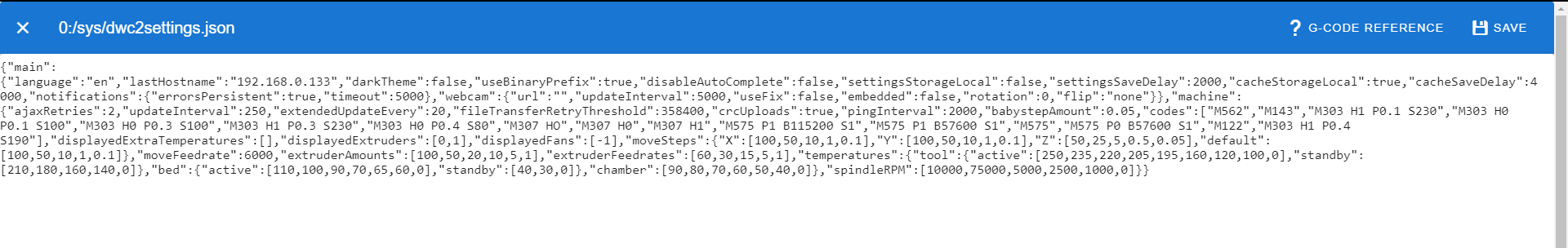

I think i might have found the problem with paneldue below is the DWC Line code for Baud Settings i think 115200 should not be their. Opinon

"M575 P1 B115200 S1","M575 P1 B57600 S1","M575","M575 P0 B57600 S1"

-

@94118 said in Help: Temp Sensors and Homing Issues:

DWC Line code for

What does that mean? Can you post a screen shot? Use the windows "snip" tool.

-

Line 4

-

That is your command history from the "console" tab in DWC. Things you have typed in the past.

Ignore it.