Surface issues - thoughts ?

-

I printed a large object yesterday! Here is a top view:

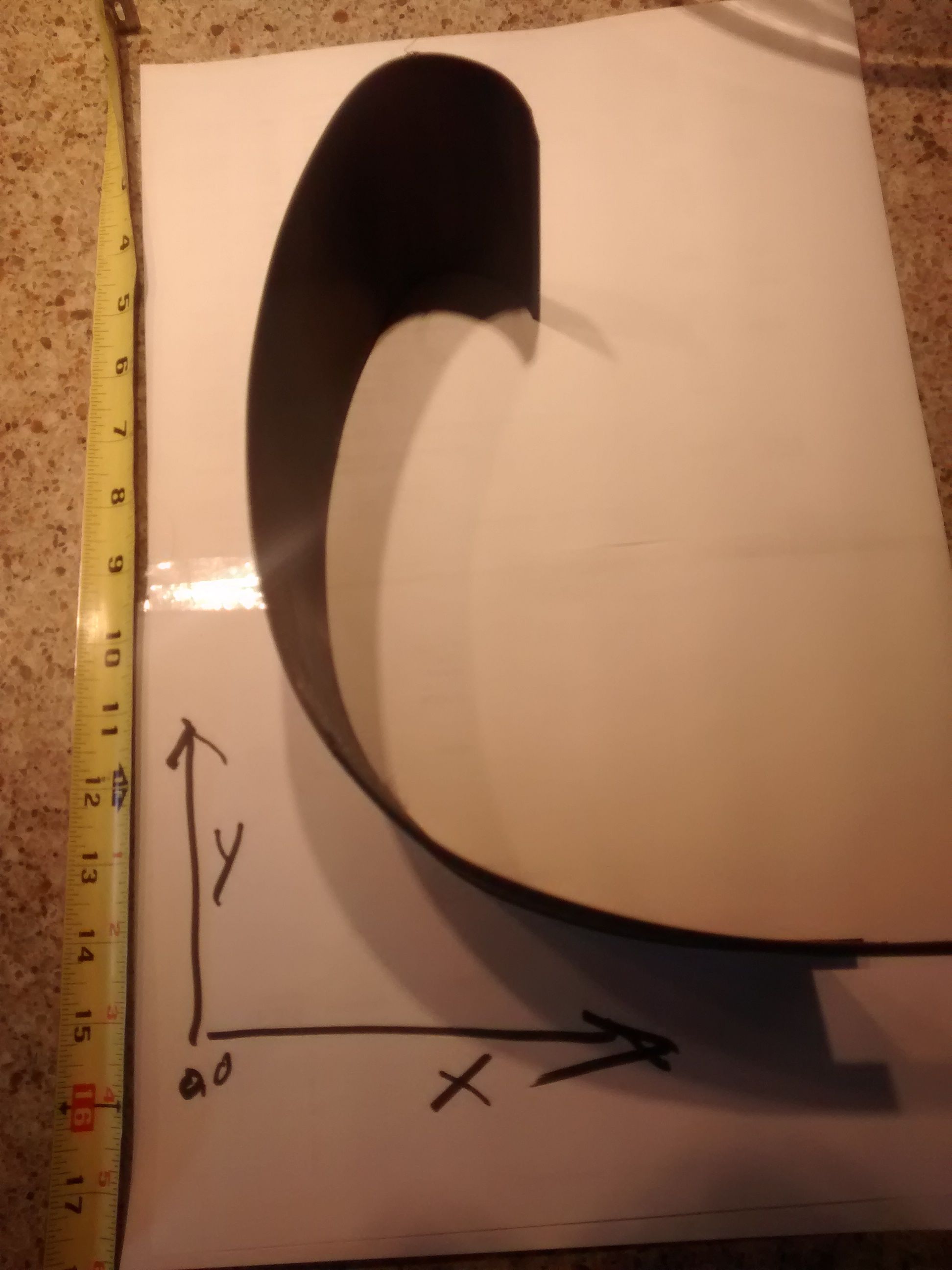

Looking at the side roughly from 0/0, I see the following:

The ugly bar is the position where the nozzle steps over to the next parallel line. I obviously haven't got pressure advance set correct but this is not what I am concerned about. When you look at the surface finish on the left of the bar it is pretty much perfect (in my eyes) but when you look on the right side it's a bloody mess.

First thought would be that there is something messed up in the x axis mechanics but by the time the bar is printed, there has already been some x axis movement but no artifacts. Also, on the other end of the print and without a surface finish picture, there is a sharper bend (see top down view) and it's surface finish is perfect.My question then would be 'what causes this kind of mess to only show up right after the nozzle moved over for the next parallel line ?

The printer is a Creality CR10-S5, the top of the print (where there is a reduction in artifacts) is tapered, no idea why the bar is less obvious for the first 20 or so mm of the print and then shows up more pronounced (mesh tapering off ?)

Printed on a glass bed, 70C for first layer, 60C afterward, PLA, 215C

-

@jens55 said in Surface issues - thoughts ?:

My question then would be 'what causes this kind of mess to only show up right after the nozzle moved over for the next parallel line ?

Are you printing external perimeters first?

Wavy lines like that are usually due to lack of pressure at the start of the line, usually from ooze during a travel.

I've also seen it happen when there was tension on the filament from the roll resisting movement and then finally releasing when the roll lurched forward.

-

- Yes, I am printing outer before inner wall.

- I can see wavy lines at the start from lack of pressure but we are talking several inches of print and not just the start section. Also, wouldn't some of that show up on the other side of the step-over point ?

- I am using a bondtech clone extruder and I could pretty much hang the entire spool directly off it and it would still feed fine so this seems to eliminate that.

I do have flat idlers all over the machine with the ribbed portion of the belt riding on the flat surface but then why is everything to the left perfect ?

I should note that the back side of the ugly portion isn't as ugly and has none of the rippling features of the front surface but there are some lengthwise artifacts .... they mostly stop opposite the seam on the front.

The seam area has a few whisps of filament about 3/4 to the right of the picture

You can see the pronounced horizontal lines. -

I started the print over with 3 changes:

I tightened the X axis

I re positioned the print on the printbed which also moved the step-over into a corner

I removed the 'print outside wall first' optionI will also tweak pressure advance a bit as it does it's thing

It's a 13 hour print so I won't have a result until tomorrow.

-

@jens55 said in Surface issues - thoughts ?:

I removed the 'print outside wall first' option

That will definitely hide the surface problem, but it doesn't really solve it.

I would say it's really a matter of retraction and pressure advance tuning and slicer retraction settings.

-

@Phaedrux, thanks! It is difficult to run multiple prints with a single change when the print is 13 hours long but I will keep this in mind and play first with pressure advance and with printing the outside wall first. Retraction settings are a bit of a mystery to me beyond the fact that too much retraction will quickly lead to a clogged nozzle. I am currently running 1.5 mm which may sound low but with a pressure advance of 1.0 ( around 800 mm for the bowden tube) I get extra retraction at the end of a move and I am hesitant to increase that. Retraction speed is at 30 mm/sec.