Thin wall cube with multiple thickness

-

How are you measuring it?

-

@mrehorstdmd with a caliper

-

My belts have different tension

-

I would not expect belt tension to cause that sort of problem. Is this a corexy machine? If so, belt tension is what keeps the X and Y axes square. If the axes are square, the belts should be OK unless they are super loose.

Is the bed trammed with the XY plane of the printer? If the right rear corner is higher than the left front corner it might do something like this. If you print a square that's 100 mm on a side does it do the same thing?

A very small print at the center of the bed will be tolerant of a lot of bed tilt, but a larger print will not...

Don't use a 20mm object to calibrate. It's too small. Use as large an object as you can measure. If you have a 6" caliper, print a 100 mm square. You'll be able to check squareness of the axes by measuring the diagonals (they should match if the axes are square).

-

-

Actually, a tilted bed should only affect line widths on the first layer.

How thick are the layers and how big is the nozzle?

-

First layer 0.1mm then 0.2mm for others, with 0.4mm nozzle

-

Doe you have access to a microscope?

-

No, why ?

-

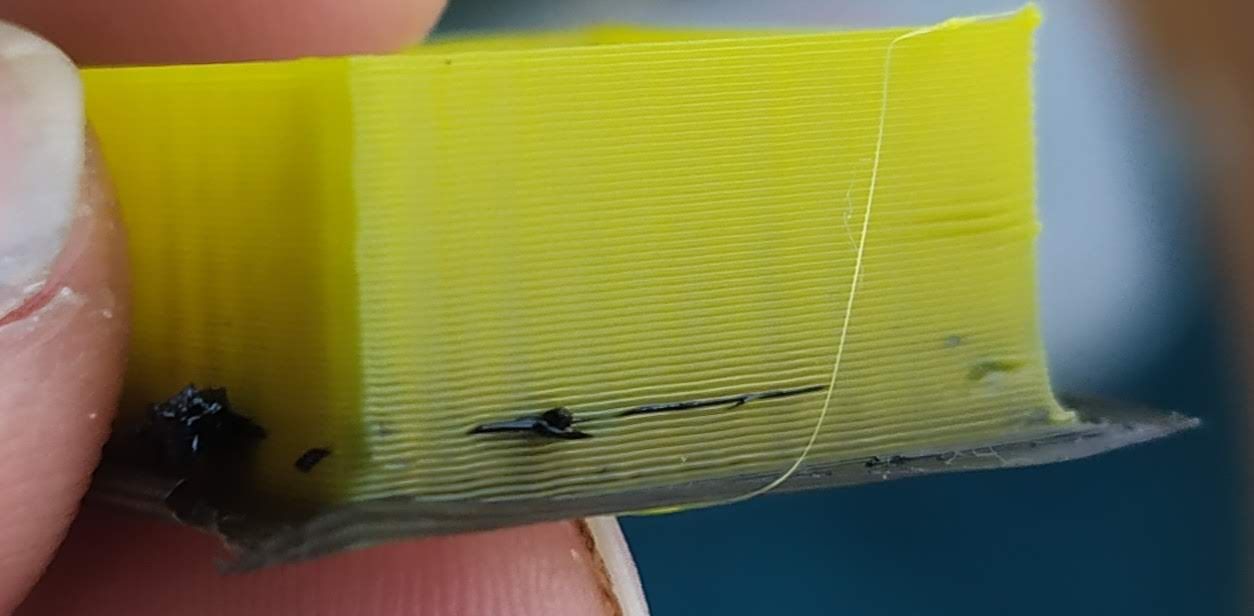

I would be good to take a look at the quality of the lines being laid down.

What sort of extruder calibration did you do? If it's under extruding you might see some variation in the line width...

Can you take some close up pictures of the print?

-

-

@pipersw said in Thin wall cube with multiple thickness:

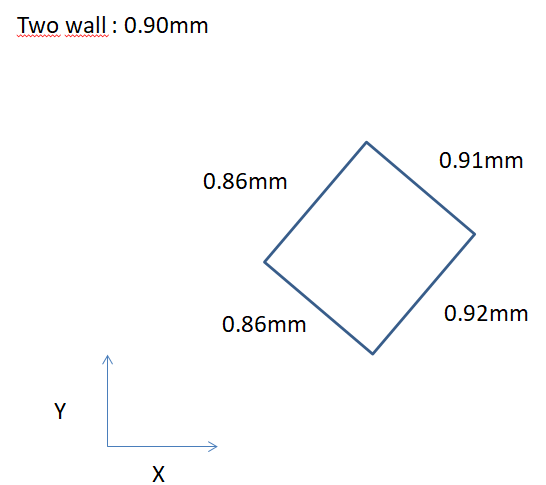

scale at 200%, with two wall (0.90mm) :

less difference between the walls.It's a core xy

What do you think ?

Unless your caliper is a several hundred dollar high end unit with an extra digit at the end that you do not show, these measurements are well within the range of normal.

Consider the fact that a digital caliper (assumption re digital) has a base error of +- 1 to begin with and this is before you get to caliper accuracy or 'operator error'.

When I say 'operator error' let me give you an example: I am measuring a piece of thick paper stock. With a light hand it reads 0.83 mm but with more pressure applied to the jaws it reads 0.66 mm. Same caliper, same item measured, just measured slightly different.

Add to that the fact that the layers may not line up totally on top of each other or that you have variances in the extrusion pressure (which may very well result in a bead that is slightly fatter or slightly thinner at any one point) and you can clearly see that you are asking for the impossible. Remember that calipers will measure across any high spots and what you are measuring is full of highs and lows.

The pictures you have posted show a nice even bead that is excellent. Don't get hung up on those readings! -

If you're trying to measure wall thickness for extruder calibration, try this method instead: https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

Then if you want to measure dimensional accuracy, print a larger complete cube and measure total width on the sides and on the diagonals.