Issues with dual extrusion and Prusaslicer with Duet 2

-

@Danal generating the gcode for mine shows it doesn's define a tool in the m104 codes. /could that be it? i dont want to have to manually change the start gcode every time i change extruders, as i have one .4 nozzle and one .5 nozzle.

the start gcode should still be handling temps correct?

; generated by PrusaSlicer 2.2.0+win64 on 2020-03-29 at 19:11:58 UTC ; ; external perimeters extrusion width = 0.56mm ; perimeters extrusion width = 0.56mm ; infill extrusion width = 0.56mm ; solid infill extrusion width = 0.56mm ; top infill extrusion width = 0.50mm ; first layer extrusion width = 0.60mm M107 M280 P3 S160 I1 ; Alarm Release and Push-Pin UP M572 D0 S0.8 M572 D1 S0.8 ;Pressure Advance M572 ; D# = Extruder # ; S = K Value (0.2 is start point tune up or down from there (current bowden length about 600mm)) ;M104 S210 ; set extruder temp M140 S60 ; set bed temp T1 ; temp fix G10 P1 S210 ; temp fix M190 S60 ; wait for bed temp M109 S210 ; wait for extruder temp G28 ; Home Printer G29 ; run bed compensation script G1 X10 Y10 Z0.3 F3600 ; Move to front left corner G92 E0 ; zero extruded length G1 E10 F300 ; purge blob G92 E0 ; zero extruded length G1 X10 Y110 E20 F1800 ; purge line G92 E0 ; zero extruded length G1 E-2 F800; ;End of Start.gcode G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion T1 ; Filament gcode G1 Z0.300 F15000.000 G1 E-2.40000 F1200.00000 G1 X132.692 Y77.794 F15000.000 G1 E2.40000 F1200.00000 G1 F1800.000 -

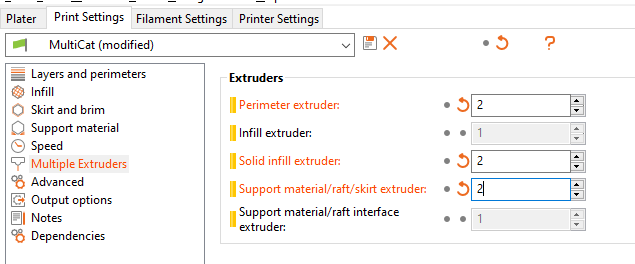

I just tried a single STL, with the extruder "overriden" as shown below. It properly generated everything for Tool1 (Toll 0 is the first, Tool 1 the second, etc). In particular:

M107

M190 S60 ; set bed temperature and wait for it to be reached

M104 S215 T1 ; set temperature

M109 S215 T1 ; set temperature and wait for it to be reached

G21 ; set units to millimeters

G90 ; use absolute coordinates

M83 ; use relative distances for extrusion

T1I take it that is not what you are seeing?

-

@Danal correct. No Tool defining in the gcode for the temps, unless i add it manually. Is your temp gcode part of your start gcode or is it auto generated?

-

It shows up. My "start gcode" box on the printer settings tab is blank.

How are you 'convincing' the slicer to print the one STL on the second extruder? Same as the screenshot above?

-

@Danal Yep. although i think you just helped me solve it. you have no temps in the start gcode? thats where mine differs. ill try removing it and see what happens

-

I don't see a set bed temp in your gcode either. Is it further down?

M190

-

@Danal line 26 has bed temp

-

Got it. I just missed it with my eye, somehow.

Hmmm.... Let me upgrade to the latest release, I'm on 2.0.0 right now. Be a min or two...

-

Okay so deleting The temps from the start gcode solved it I believe. I have a print running right now, but ill try it afterwards, but the gcode reflects the fix.

-

Good. I'm still going to install 2.2, just because

-

@Danal Okay so deleting it kinda fixed it but not really. It does auto add the code for the tool requested, but will try to print before the extruder is up to temp. I dont know why.

-

adding an M109 S[first_layer_temperature] cause it to heat up the wrong extruder

-

Adding an M116 seems to have done the trick, however, i get an error message saying that tool 0 didnt move because it never got up to temp, possibly because it is set as active by default (although im not using is to why even prompt me?), and the second extruder only gets set to active when the standalone T1 command is executed in gcode. I would leave it, but i dont want an error message every print, as it concerns me.

-

Waiting for the tool is not up to the slicer. Be sure you have a "M116 H2 " near the beginning of your

/sys/tpost1.g

file. Actually tpost0.g and tpost1.g

If you don't have those files, create them.

-

@Danal

M116 H1 in the tpost0 and H2 in tpost1 as they refer to heater number, or h2 in both? -

@Turbo said in Issues with dual extrusion and Prusaslicer with Duet 2:

@Danal

M116 H1 in the tpost0 and H2 in tpost1 as they refer to heater number, or h2 in both?Heater number. Which, in my config, is Tool Number + 1. Because H0 is bed.

-

@Danal After including that, nothing seems to have changed. when it goes to start the purge line i configured in the start gcode, it doesnt extrude because its not up to temp, defeating the purpose

-

@Turbo said in Issues with dual extrusion and Prusaslicer with Duet 2:

@Danal After including that, nothing seems to have changed. when it goes to start the purge line i configured in the start gcode, it doesnt extrude because its not up to temp, defeating the purpose

It should be waiting on that line in the toolchange macro. You may need a T-1 (unmount all tools) in the startup.

-

@Turbo Use G10 S and R to set the active and standby temperatured. You need to put the commands in your slicer start gcode. I'm trying to remember how I had multiple tools set up years ago when I used a Mendel Tri- colour. I'm fairly sure that's all I had to do. When changing tools, the firmware waits (or it used to) for the new tool to reach the active temperature and (I think) the old tool to cool to the standby temperature. No need for any commands other than Tn. These days, I use up to 9 tools but they share a common heater so all I have to do is put G10 Pn Snn Rnn for each tool in the start gcode and use the same value for S and R.

-

@deckingman, the goal is to not change the default Slicer3pe start gcode.

Part of this is based on the fact that I am using a multi-tool printer, and my "custom start gcode" is blank, and it works (properly heats tools at the right time, etc)

So another phrasing could be: Why would @Turbo have to use custom start gcode when others don't?