Making it fit

-

@TinkerBill

One option might be to place it below the frame, adding feet. -

@DIY-O-Sphere I started debating to/on one side, rather than internal. Feet is a good call though, might do that. Thanks

-

@TinkerBill said in Making it fit:

Picture an equilateral triangle, with a circle touching the middle of each edge. Then make each edge longer, the circle will need to be larger.

or you could design mounts that allows you mount the existing bed inside a larger triangle; however in my world cutting new extrusions is way $$$ so I'd consider moving the duet to the top instead maybe?

-

@bearer the current extrusions are 230mm so I can get longer ones relatively easily online (circa £30-40 for the set from oozenest) rewiring to the top would mean making a new loom for a lot of the components which I'd rather avoid (currently don't have most my tools....)

-

if you throw together a sketch of your current bed, incl mounting holes and the potential new extrusion lengths we might be able to suggest some mounting options

-

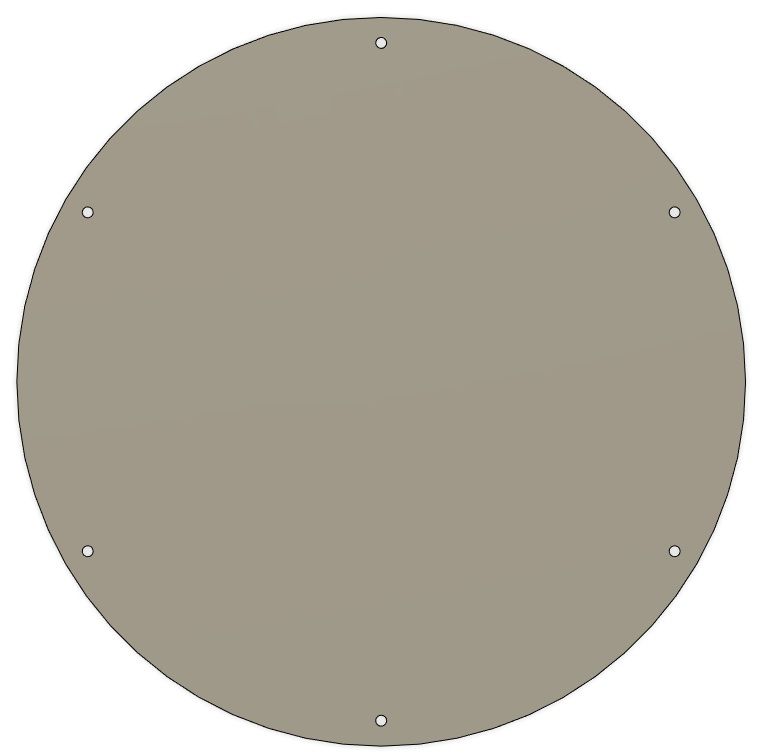

@bearer Current bed is 200mm diameter, 6 3mm holes seemingly evenly spaced around it, 7mm inset from edge to center of the hole. Pic is a brief sketch I threw together on F360.

New extrusions can be pretty much whatever length, though I'd probably max out at 300mm to keep the footprint small.

-

@TinkerBill said in Making it fit:

@fcwilt As it's a delta, with the print bed attached to the top of the base extrusions, extending the base extrusions will change the distance between the center of each extrusion where it currently mounts. Picture an equilateral triangle, with a circle touching the middle of each edge. Then make each edge longer, the circle will need to be larger.

But the print bed doesn't need to attach directly to the extrusions.

Make some mounting plates that attach to the extrusions and extend as needed to support the print bed.

Frederick

-

@fcwilt I don't have the tools to make something with sufficient precision unfortunately

-

When I found that my horizontal extrusions were a little too short, I printed short spacers to put at the ends. The spacers are short enough so that the vertices still screw into the extrusions.

-

@TinkerBill said in Making it fit:

@fcwilt I don't have the tools to make something with sufficient precision unfortunately

You have a 3D printer - that's what I used to make the pieces I needed - back when I had my delta printers.

Frederick

-

here is another idea.

print these https://www.thingiverse.com/thing:2519593

they will also provide good noise dampening.now you have space underneath the delta where you can mount the duet without interfering with the motors.