3D printin issues on a core XY equiped with a duet wifi

-

I started reprinting the part to see when the layer change takes place. I did notice however that at the height of 0.4mm the part started to gain a big blob arount one of the holes

-

the nozzle could easily catch on that and cause the layer shift.

btw what material is that? because the print quality looks very poor

-

@Veti yes, I suspect that too. I am trying however to figure out what can cause that.

-

post your config.g

-

@Veti Bellow you have the config.g file:

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Oct 05 2020 11:50:08 GMT+0300 (Eastern European Summer Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Oscar" ; set printer name

M669 K1 ; select CoreXY mode; Network

M551 P"" ; set password

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S0 ; disable Telnet; Drives

M584 X1 Y0 Z2 E3:4 ; set drive mapping; INIT:X=0; Y=1; Z2;E3:4

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes FORWARDS

M569 P3 S1 ; physical drive 3 goes FORWARDS

M569 P4 S0 ; physical drive 4 goes backwardsM350 X16 Y16 Z16:16 E16:16 I1 ; configure microstepping with interpolation ; INIT- M350 X16 Y16 Z16 E16:16 I1

M92 X160.00 Y160.00 Z3200.00 E843.26:830.8 ; set steps per mm

M566 X600.00 Y600.00 Z12.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)set x and y to 600 from 900

M203 X6000.00 Y6000.00 Z360.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X250.00 Y250.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)x and y 250 from 500

M906 X1100 Y1100 Z1200 E1200:1200 I80 ; set motor currents (mA) and motor idle factor in per cent changed X1200 Y1200 to X1100 Y1100

M84 S30 ; Set idle timeout

; Pressure advance

M572 D0:1 S0.05:0.05 ; enabled Pressure advance for both extruders; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X600 Y600 Z525 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop -added "! to xstop"

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop - added"! to xstop"

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X20 Y37 Z2.32 ; set Z probe trigger value, offset and trigger height- changed from 3.5 to 2.19 to -0.797,to 2.23to 2.316

M557 X40:520 Y80:520 P20 ; define mesh grid changed S20 to P3 to P20; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S250 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P0 S"Tool 1" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Tool 2" D1 H2 F1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined

M912 P0 S-16.95 ; adjustment of the MCU temp read; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

M501 ; load saved parameters from non-volatile memory -

@campeancalin said in 3D printin issues on a core XY equiped with a duet wifi:

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1tempyour thermistor setting is wrong. look up the correct beta value in your thermistor documentation.

because of it you are printing at the wrong temperature.what material is that you are printing?

-

@Veti ColorFab XTCF20

-

the printheads are 24V E3D V6

-

after changing the B values do I have to redo the PID tunning?

-

@campeancalin said in 3D printin issues on a core XY equiped with a duet wifi:

the printheads are 24V E3D V6

if they are genuine e3d then you need 2 values

B4725 C7.06e-8This will account for about 20 degrees difference at 200C

i would do a pid tune, but the pid value should not change by much.

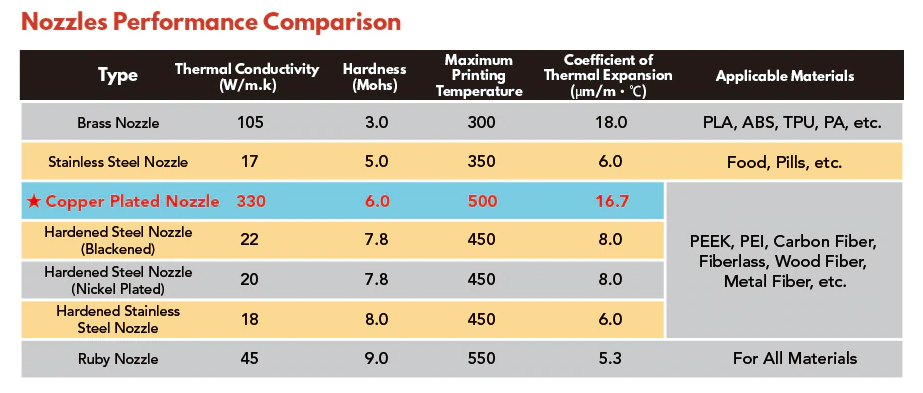

btw what nozzle are you using? the carbon filament will destroy a normal brass nozzle and could also account for the blobs you are seeing

-

@Veti It's not a brass nozzle ; reinfoced steel. I plan on having a look at it after it's gone thru a spool of filament.

-

@campeancalin said in 3D printin issues on a core XY equiped with a duet wifi:

reinfoced steel.

that is ok for wear, but very bad for temperature transfer.

i would suggest that you print a temperature tower.

-

I have a little problem with the PID tunning. Once I've changed the values , it gives me the following error message:

M307 H1 S285Error: M307: bad model parameters

-

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S250 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit -

@campeancalin M303 is used to PID tune, not M307

-

@jay_s_uk Thank you

-

@campeancalin said in 3D printin issues on a core XY equiped with a duet wifi:

M143 H0 S250 ; set temperature limit for heater 0 to 120C

can you bed really reach 250C? the bed does not look like the special e3d high temperature bed. and those can reach 250, but should not be operated above 200C

-

@Veti No. I've PID tunned it for a max temp of 100 C

-

@campeancalin PID doesn't set a max temperature, the M143 does.

-

@campeancalin

Looking at the pictures, either you are over-extruding or your first layer is too low (which means you are trying to fit too much material in too little space). That causes material to push up higher than it should, and if the nozzle runs into those lumps it tends to cause layer shifts.And if you don't have one already, get a filament drier, CF filled filaments absorb moisture like crazy and need to be dried. If you look closely you might be able to see the filament bubbling as it comes out of the nozzle. Drying the filament for at least 24 hours will make a huge difference to both print quality and material strength.