Connectors for flexible testing

-

@arhi Thank you for the proposal, I'll check it. They are expensive however, because I need multiple connectors for testing.

I thought about something with Pogo pins, but I prefer a commercial connector.

-

what kind of insertion force, accuracy and locking mechanisms are acceptable?

and just the 4 pins á 5A?

-

@JoergS5 said in Connectors for flexible testing:

@arhi Thank you for the proposal, I'll check it. They are expensive however, because I need multiple connectors for testing.

you can sometimes score them second hand unused ... e.g. these a friend found for fraction of cost:

I thought about something with Pogo pins, but I prefer a commercial connector.

I'm trying to design something with pogo pins for the extruder for years and never came to a solution I like

I use PRC connectors myself

... they are much harder to solder than original's, do not nearly last as originals but are fairly cheap

... they are much harder to solder than original's, do not nearly last as originals but are fairly cheapI love these

they are 5A rated but I was running 10A for 5 hours for test without any issues ... and they are dirt cheapsometimes I use these, but these you have to be careful when plugging and unplugging and are nightmare to solder but still dirt cheap

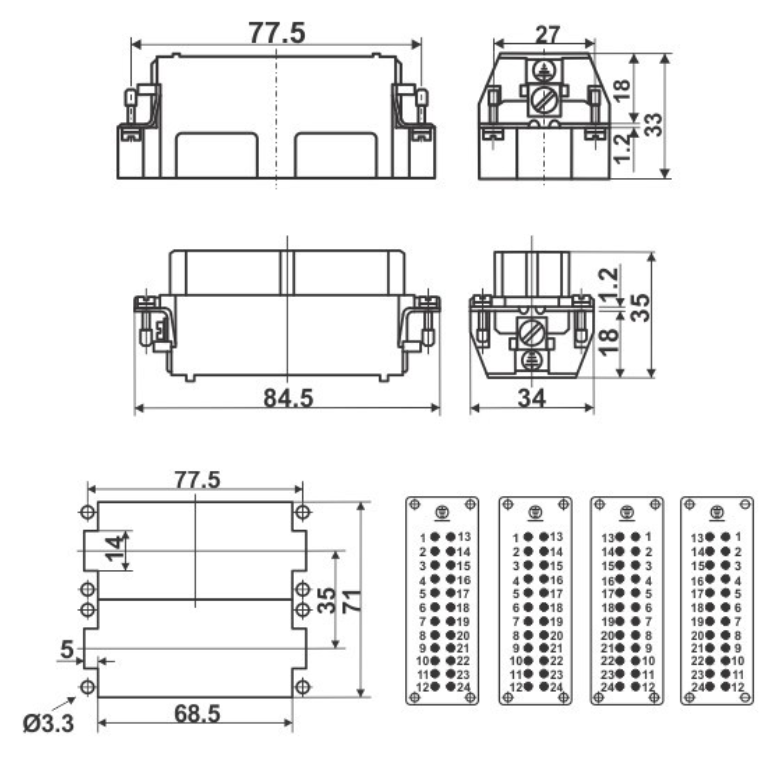

These PRC ones are great, only they are not cheap and they are very big/bulky, so I use them on big machines but are not really useful for 3d printers as the connector is huge

.. and they are expensive

.. and they are expensive

-

@arhi thank you for your hints. I missed the alert somehow, sorry.

I have researched and found the following additonal possibilities:

- banana jack

- MPX high current

- EMC high current

- XT30

- HCPM-5

- XLR = Cannon connector would be also nice, but is used for audio

I am still searching for a good solution, but will design it together with a toolchanger design probably. Pogo pins seemed to be interesting, but they are so small to handle, will be difficult...

Currently I use Wago 221, they are reliable, but the wiring mess looking ugly (every Stepper 4 Wago-s).None of the connectors have something to grab it with a robot and helping with positioning it.

-

If you are testing steppers why do you need 5A? That's a lot!

Personally I normally start by browsing through someone like Molex's catalog.

https://www.molex.com/molex/products/group/wire_to_wire_connectors

And its not hard to find the right SLC's for up to 9A. You still need to make the actual connector, but the pins are out there.

You could also just make a breakout PCB, that has the same molex KK connector that is on the Duet, and has wires that go back to the Duet. That way everything is still the same connector (and you can even add some indicator LED's to the board, which can help with troubleshooting).

I'd probably do the PCB option myself.

-

@theruttmeister the 5 A was not the important part of my question, I only wanted to express that it's not only for signals, but also for energy transfer. The main focus of my question was to find a connector which can be used by an automated process for assembling and disassembling.

I would like to find a connector- to connect easily by a few actuators by a robot e.g. (position, move together, lock/unlock)

- connect and disconect with location tolerance and few force (1 N)

- variable pin count

- enought current (5A as example), small, secure, not too expensive

I am a bit surprised that I cannot find such connectors. I thought about how to automatically let build a 3D printer and wanted to start with an "easy" part, electronic connections. I didn't expect that I have to invent my own. (joke)

-

@theruttmeister said in Connectors for flexible testing:

You could also just make a breakout PCB

that's a good idea, I will think about it, thank you! This will also allow to switch between Duet 2 and 3 easily for testing.

-

I have multiple "pig tail" looms made up so I can quickly swap between boards and between components it gets to a point in where you have generally made enough adapters up to cover everything you are doing.

-

@CaLviNx I get a funny german translation for "pig tail looms"

I'll try the adapter idea. It is time consuming to assemble/disassemble single wires (and sometimes a connection fails, which is a danger for the board). -

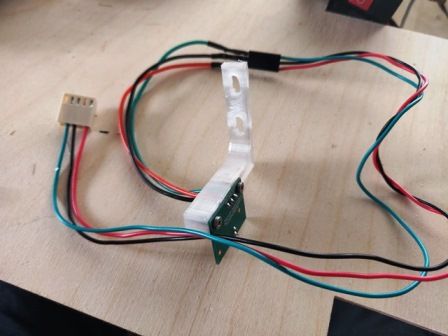

For example if I want to quickly test an IR sensor that has been plugged into a LC-1 Tool-board and I want to try it directly into a Duet-3 I have the following, simple and fast.

-

@CaLviNx thanks for the example, this is a good approach. Most of my wirings are too short anyway (the stepper wiring eg), so a PCB in the middle solves two problems.