RepRapFirmware 3.2beta3.2 released

-

The main features of this release are:

- Fixes for communication issues with SBC

- New heater tuning algorithm and feedforward heater control

Get it from the unstable package feed if you are using a Duet 3 + RPi, or from https://github.com/Duet3D/RepRapFirmware/releases/tag/3.2beta3.2 otherwise. The release notes are at https://github.com/Duet3D/RepRapFirmware/blob/v3-dev/WHATS_NEW_RRF3.md.

-

i take it you can now tune heater on the toolboard?

because https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitations

says its planned for 3.3 -

No, you can't tune heaters on Duet 3 tool and expansion boards yet. If I get enough feedback on the new heater tuning algorithm then I may be able to implement it before 3.2 release.

-

@dc42 I can now say, that tuning for tool works perfectly fine for my printer. Seems a little strange, as temperature fluctuates during the tuning, but after that, it holds temperature perfectly.

-

The temperature deliberately fluctuates by somewhat more than 5C during tuning, to allow the heating and cooling rates to be measured. It does 2 cycles to start with to let the temperatures settle, then 5 to 30 cycles with the print cooling fan off, then if you are running a tool another 5 to 30 cycles with the fan fully on. The number of cycles it does depends on how consistent the measurements are. If there is noise in the temperature readings, it will do more cycles. If it does the maximum 30 cycles and the results are still not consistent, a warning is output.

-

@dc42 Well it did exactly that. And results are very good. Basically straight line on chart. even with variable fan speed during the print.

-

Thanks for the feedback!

-

Extruder tuning worked fine for me too - rock solid line during first print. Bed tuning did 30 cycles, but seems to be working fine. This is a fairly low powered bed tuning to 60deg - each 5deg cycle took about 3.5min. This is with a stand alone 1.01 Duet2wifi.

-

This post is deleted! -

What's saved in config-override.g with M500:

M307 H0 A424.4 C543.6 D5.5 S1.0 V24.1 B0What the M303 H0 S90 came up with:

M307 H0 R0.781 C543.6 D5.54 S1.00 V24.1Is the M500 supposed to change the M307?

-

@Stephen6309 said in RepRapFirmware 3.2beta3.2 released:

What's saved in config-override.g with M500:

M307 H0 A424.4 C543.6 D5.5 S1.0 V24.1 B0What the M303 H0 S90 came up with:

M307 H0 R0.781 C543.6 D5.54 S1.00 V24.1Is the M500 supposed to change the M307?

Yes, M500 is supposed to rewrite config-override.g including the new model parameters. I can't see anything wrong with the code, so I will try to reproduce your observation.

-

@dc42, @chrishamm, after updating to the latest release i am having assertion problems again.

I publish the report. Let me know if you need more information or if I need to checkm122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.2-beta3.2 running on Duet 3 MB6HC v0.6 or 1.0 (SBC mode) Board ID: 08DJM-956L2-G43S4-6JKF0-3S86T-9A5YD Used output buffers: 1 of 40 (22 max) === RTOS === Static ram: 122236 Dynamic ram: 140444 of which 24 recycled Never used RAM 129488, free system stack 170 words Tasks: Linux(ready,75) HEAT(blocked,275) CanReceiv(blocked,878) CanSender(blocked,371) CanClock(blocked,352) TMC(blocked,51) MAIN(running,1159) IDLE(ready,19) Owned mutexes: HTTP(MAIN) === Platform === Last reset 01:15:05 ago, cause: software Last software reset at 2020-11-15 10:23, reason: AssertionFailed, GCodes spinning, available RAM 128744, slot 0 Software reset code 0x4123 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0040080f BFAR 0x00000000 SP 0x2045fea4 Task MAIN Stack: 00000193 00488688 00469673 00000001 2043ff1d 2043fe50 2043eab0 2043fb80 20438118 00000001 20438090 204381b4 204381b0 00000003 0046ea21 00000003 00433a0b 00000001 20420b20 20437970 20420b20 2042ac70 040023b6 204375b0 00000002 2042ab10 000249f0 Error status: 0x00 MCU temperature: min 23.3, current 23.4, max 24.5 Supply voltage: min 24.1, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.0, current 12.1, max 12.1, under voltage events: 0 Driver 0: position 0, standstill, reads 21669, writes 19 timeouts 0, SG min/max 0/0 Driver 1: position 0, standstill, reads 21670, writes 19 timeouts 0, SG min/max 0/0 Driver 2: position 0, standstill, reads 21673, writes 17 timeouts 0, SG min/max 0/0 Driver 3: position 0, standstill, reads 21673, writes 18 timeouts 0, SG min/max 0/0 Driver 4: position 0, standstill, reads 21674, writes 17 timeouts 0, SG min/max 0/0 Driver 5: position 0, standstill, reads 21675, writes 17 timeouts 0, SG min/max 0/0 Date/time: 2020-11-15 11:38:49 Slowest loop: 6.98ms; fastest: 0.15ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 375, MinFreeDm: 375, MaxWait: 0ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed moves 0, StepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, StepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = 3 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon* is doing "G4 S60" in state(s) 0 0, running macro Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === CAN === Messages sent 18038, send timeouts 18038, longest wait 3ms for type 6039, free CAN buffers 47 === SBC interface === State: 0, failed transfers: 0 Last transfer: 21ms ago RX/TX seq numbers: 9476/13409 SPI underruns 0, overruns 0 Number of disconnects: 0, IAP RAM available 0x20a30 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.2.0-beta3 Daemon: Buffered code: G4 S60 ; delay running again or next command for at least 60 seconds ==> 32 bytes Executing macro daemon.g, started by system > Next stack level Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 31.79 -

@dc42, @chrishamm, I checked, it seems that problem is due to restart of printing after a stall. For the moment I have tried increasing S value in M915 to see if it repeats again.

-

@dc42 just to let you know, the new auto tune works well on my coreXYUV Duet 2 machine with RRF 3.2beta3.2

Thank you for all your hard work. -

@Marco-Bona said in RepRapFirmware 3.2beta3.2 released:

@dc42, @chrishamm, I checked, it seems that problem is due to restart of printing after a stall. For the moment I have tried increasing S value in M915 to see if it repeats again.

Thanks for the update. How did you have the stall detection configured when you had the problem?

-

@dc42, the code was this:

M915 X Y T20000 S12 H128 F1 R3In all honesty I never understood how to calibrate it correctly but with this values it gave good results.

I simply increased the S value from 12 to 15. I can't tell you if the same assertion problem also occurs after resuming a print from a pause.

If you need feedback I can give it a try. -

@dc42 said in RepRapFirmware 3.2beta3.2 released:

Thanks for the feedback!

Thanks for the feedforward HEYOOOOO

-

Duet2Wifi, copper E3D v6 heaterblock with 50W cartridge and PT100 heater 1, aluminium E3D v6 block / 50W heater / thermistor on heater 2, 300x300x10mm aluminium bed with 600W silicone heater on heater 0.

Auto tuning heater 1 using target temperature 250.0°C and PWM 1.00 - do not leave printer unattended 16-11-2020 09:35:27 M303 H1 S250 16-11-2020 09:39:11 Auto tune starting phase 3, fan off 16-11-2020 09:42:18 Auto tuning heater 1 completed after 5 cycles in 411 seconds. This heater needs the following M307 command: M307 H1 R2.029 C335.3 D5.90 S1.00 V23.8 Edit the M307 H1 command in config.g to match this. Auto tuning heater 0 using target temperature 70.0°C and PWM 1.00 - do not leave printer unattended 16-11-2020 09:43:41 M303 H0 S70 16-11-2020 09:43:46 Auto tune starting phase 1, heater on 16-11-2020 09:48:42 Auto tune starting phase 2, heater settling 16-11-2020 10:09:03 Auto tune starting phase 3, fan off 16-11-2020 10:45:51 Auto tuning heater 0 completed after 5 cycles in 3728 seconds. This heater needs the following M307 command: M307 H0 R0.176 C2246.3 D40.12 S1.00 V24.0 Edit the M307 H0 command in config.g to match this. Auto tuning heater 2 using target temperature 220.0°C and PWM 1.00 - do not leave printer unattended 16-11-2020 12:10:43 M303 H2 S220 16-11-2020 12:10:48 Auto tune starting phase 1, heater on 16-11-2020 12:12:13 Auto tune starting phase 2, heater settling 16-11-2020 12:14:00 Auto tune starting phase 3, fan off 16-11-2020 12:17:12 Auto tuning heater 2 completed after 5 cycles in 388 seconds. This heater needs the following M307 command: M307 H2 R2.328 C287.2 D6.31 S1.00 V23.8 Edit the M307 H2 command in config.g to match this.Especially the bed took quite a while, but that's a lot of thermal mass.

I am not noticing much better PID behaviour when the print cooling fan is suddenly turned on from 0% to 100%; without silicone sock the hotend temperature drops ~6 degrees C and recovers fairly slowly. 100%->0% gives a 5-6 degree C overshoot. RRF3.1.2 behaves about the same under that condition.

-

@DaBit Try using the tool number rather than the heater number so:

M303 T0 S250

assuming H1 is the heater for T0. If you do this then the tuning will run an extra cycle with the cooling fan for tool 0 active and you will get some extra params which may help with your temperature drop. -

Thanks for the hint, 'old' habits I guess..

Makes not much difference though. Recovery from fan torturing is slightly faster, temperature deviation stays approximately the same with -6.5C /+5C.

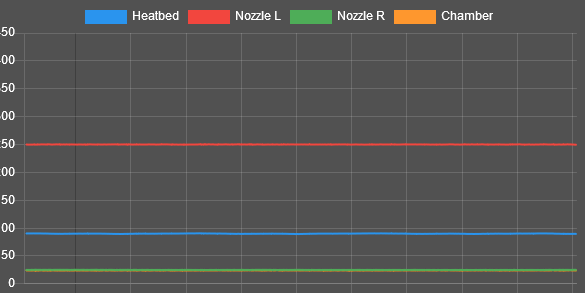

16-11-2020 20:15:57 M303 T0 S250 Auto tuning heater 1 using target temperature 250.0°C and PWM 1.00 - do not leave printer unattended 16-11-2020 20:16:02 Auto tune starting phase 1, heater on 16-11-2020 20:17:57 Auto tune starting phase 2, heater settling 16-11-2020 20:19:39 Auto tune starting phase 3, fan off 16-11-2020 20:22:48 Auto tune starting phase 3, fan on 16-11-2020 20:26:13 Auto tuning heater 1 completed after 10 cycles in 615 seconds. This heater needs the following M307 command: M307 H1 R1.941 C335.4:173.7 D6.34 S1.00 V23.8 Edit the M307 H1 command in config.g to match this.Cooling fan turn-on / turn-off event, no silicone sock:

Of course, I could improve a lot on this by making fan airflow more directional towards the print, but there is no print-quality reason to do so. Better save those lessons learned and time to resolve them for printer #2. There are more things that did not work out as expected and need improvement, such as the E3D Chimera.

I normally use silicone socks around the heater block, especially when printing small items, although at 250-270C hotend their lifespan is a bit limited.

Is there a reason why we don't have a derivative term in the controller? Or is that derived internally from the R/A, C and D parameters? The D usually works fine dampening an otherwise too agressive P and reacting to fast environmental changes.