Duet3 config Frustration

-

@Rushmere3D said in Duet3 config Frustration:

Reading this might also be useful for the setup.https://duet3d.dozuki.com/Wiki/Connecting_and_configuring_fans

This page seems to be more on the RepRap v2.x and less on v3.x that is on the Duet3.

One of the items I do not fully understand is what F1:2 means. Is that two different fans as lined up on the Configurator website (Fan0 to 3)? Or is that just the location of a single fan as they could be on any number of external (or internal) boards?

The fan wiki page only shows one number after F.

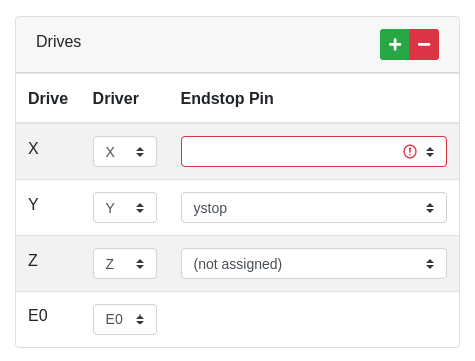

Does this mean fan 0 and fan 3 (F0:3 )? If yes, that doesn't make any sense as I set 0 and 1 to Left Extruder, and Fan 2 and 3 to the Right Extruder in the configurator. I did have to make a change, because config right out of the configurator turned the hotend cooling fan on the right extruder, when I heated up the left hotend. I was able to fix the left hot end cooling fan to enable when it hit 40c, but now not sure why the right hotend fan will not go on at all. And do not understand how to read the F0:3 attribute.

All I know for sure is that this tool isn't working.

M563 P1 S"RightExtruder" D0 H0 F0:3But the fans work fine on the Left Extruder.

M563 P0 S"Left Extruder" D1 H1 F1:2Thanks!

-

While I understand it can be tedious, I think it is better to configure things manually.

Your case highlights the "confusion" that people encounter when using the config tool that in all honesty only does "half a job" when it comes to setting up RRF-3.

I have a terrible memory (old age is a sick sick joke) so I keep an instance of The Duet G-Code Pinned to open every time I open my browser and with that I read, read & read that page and test so I can manually write my own config.g files, and I add my own explanation (worded in a way I understand) to the end of each G-Code line to remind me

Maybe a pictorial guide for some of some of the basic tasks is required, as I have found documentation to be scattered, sparse in places and some omissions in documentation, that was written by someone that assumes the reader already knows and understands some things.

For example when configuring a tool-board (lc-1) I have never actually found the correct info anywhere.

See below, it took me a bit of time to work out on my own that I was required to add "121" to the C parameter to get the config to know I was trying to direct it to the tool-board. if thats listed in documentation I have yet to find it.M950 F0 C"121.out1" ; The part cooling fan (fan0) is mapped/connected to out1 on the tool-board LC1 with the address being 121 -

@CaLviNx said in Duet3 config Frustration:

"121

I am not using any external boards... but that is besides the point to my questions.

How did you figure out the address to the tool board was 121?

-

@BlueDust said in Duet3 config Frustration:

@CaLviNx said in Duet3 config Frustration:

"121

I am not using any external boards... but that is besides the point to my questions.

How did you figure out the address to the tool board was 121?

I couldn't get the duet-3 to recognize a tool-board was there (the LED was flashing the correct way so there was comms) but I couldn't figure out why the DWC was showing errors, so I did a search here to see if there was anyone having the same issue, I found a post on here about someone changing the tool-board address which made me think "I wonder" and I went and added the 121 portion to all my C parameter sections and by magic my errors disappeared.

-

https://duet3d.dozuki.com/Wiki/Duet_3_Tool_Board#Section_Commissioning_a_new_Tool_Board

Don't ask me why it's 121, but it is documented in the tool board page.

-

That is 100% correct

But no-where does it actually state (that I could find) that to get the main board and tool-board to communicate with each other, that you should use that address in the C parameter of each required G-Code Command.

That is exactly what I mean about guides that "assume" that the user has prior experience with a certain types of technology, if the user has never used or encountered the tech & what is required to get it up and running how can they know if its not specifically mentioned.

Now this is not having a go, and as an Engineer I understand the trap we can fall into, when someone asks about something (something we perceive as so simple we never give it a second thought) something that we have used and understood for years so much so that when some one asks about it we are like "eh why dont you know that, that's easy"

Yes its easy for some of us because we have been used to it (and been used to using a certain technologies for a long time) but for those who might not have ever used it before we need to change out our approach, and look at it from their perspective.

-

@CaLviNx said in Duet3 config Frustration:

That is exactly what I mean about guides that "assume" that the user has prior experience with a certain types of technology, if the user has never used or encountered what is required how can they know if its not specifically mentioned.

No argument there. I'm in the same boat. The tool board canbus expansion paradigm probably makes more sense to those in the target market who may already be familiar with canbus, but for the neophyte it's not intuitive. I don't have access to the hardware myself so I haven't used it to know what the major sticking points between documentation and reality are yet. Best I can do is take complaints and suggestions for improvement and update as we go.

-

A single sentence in the documentation explaining the requirement could save people (me included) hours of frustration.

And with the can-bus tech becoming more common possibly someone could write a small section in the documentation with a brief description of the tech and how it is used/works, requirements etc.

I know and understand that when I write technical curriculum material it is a fine line of trying to get the technical point across in such a way that is not going to make the students eyes roll to the back of his/her head and they pass out, But we always make a point of giving a brief on how the technology (or specific component) works to try to provide a solid foundation on the subject.

-

@CaLviNx said in Duet3 config Frustration:

And with the can-bus tech becoming more common possibly someone could write a small section in the documentation with a brief description of the tech and how it is used/works, requirements etc.

Well there is this: https://duet3d.dozuki.com/Wiki/CAN_connection

I'll see about linking to that page from the other duet 3 hardware pages.

-

@BlueDust said in Duet3 config Frustration:

All I know for sure is that this tool isn't working.

M563 P1 S"RightExtruder" D0 H0 F0:3

But the fans work fine on the Left Extruder.

M563 P0 S"Left Extruder" D1 H1 F1:2I have made a handful of changes to Fx:x on both the left and right extruders and haven't seen any changes or swaps of the fans. Always works/can't break it making those changes. I don't know what they do.

Saying that, I fixed the right fan. It was unplugged. I thought I wrapped electrical wire around all the fan wire connections to make sure they didn't come apart while moving (connections are inside of the cable sleeve, and not seen without unwrapping the sleeve)... Will fix that.

-

@BlueDust Thanks, it's fixed now:

-

I have noticed another weird temp thing a few times, but I am not 100% sure how to reproduce it...

It seems that if I manually set (have yet to print anything), the temp on two extruders, I can only get the temp to heat up on one of them. Even though there is a temp listed, it does increase. I have to click on it a 2nd time and click enter.

I just did this...

I set the temp on two different tools (active and standby) . On the tool that was off, and moved it to standby, and then moved to Active, it wouldn't increase while in either standby or active. I had to click the temp and hit enter (didn't re-input the temp a 2nd time).Is this a bug or expected? If this is a possible bug, I will have to pay more attention what I am doing when manually playing with the temps incase I see this again.

-

@dhusolo said in Duet3 config Frustration:

Checkout my github. I have configs i've made and shared for the BLV printers. I don't know how IDEX are setup but use Cube RRF 3.1.1 but be sure to change it to what you need it for. There's wiring diagrams in the repository.

Looking at your Duet3 wiring png... It shows you have a BLTouch v2.0 in the picture. As I had to buy a new BLTouch, I received a v 3.1. is the wiring the same for both versions?

Thanks! -

@BlueDust said in Duet3 config Frustration:

As I had to buy a new BLTouch, I received a v 3.1. is the wiring the same for both versions?

yes. it should work.

one user had to enable 3.3v logic. -

@Veti

Does that mean they used the 3.3v instead of the 5v? -

@BlueDust I wouldn't read too much into it. That particular case could have been any number of things.

However, if you find you're having troubles here is the relevant doc from antclabs on how to switch between.

-

@Phaedrux

AntLabs says the BLTouch 3.1 is 5v, and don't want to confuse myself any more on this if I don't have to. I was just curious as I remember older BLTouches needed resistors or something to make them work on the Duet boards. The documentation on Antlabs website in relation to Duet seems old and trying to keep this simple as it was on the Duet2Eth as I use a BLTouch 2.2. They seem to change things up often and I don't mind making a mistake and fixing it, but don't want to break anything and have to buy a new one for something dumb I did (like not reading the instructions).3Pin: Brown (GND), Red (+5V)

Orange (control signal)

2Pin: Black (GND) White (Zmin)As always. Thanks for the help!

-

Duet3 is 5v tolerant so you shouldn't need to change anything on either the duet or BLTouch. It's been that way for a long time now. Should be plug and play.

-

@Phaedrux

Is the GPIO Port # referring to the io#.in? Where the number would match where the BLTouch is plugged in?M280 P0 S80 ; set 80deg servo position on GPIO port 0

Thanks

-

@Phaedrux

I read something on one of the Z Probe M commands and it made me think it was a heater.

Self test works now...