Jerk Control M566

-

At my eyes it seems that with so low jerk values the printhead is stopping at every STL triangle and the extruder is overextruding there due to low speed and higher temperature on the already layed plastic. I would try to increase the jerk and print speed. These result are impossibile to be caused but too high jerk. You can clearely see the mesh triangles and still the model seems to be really low on poly count.

Just my 2 cents.Note: My jerk is at 900 in a medium size corexy with directdrive extruder so i think your values are really too low also with taking account of a heavy toolhead.

-

@MikeS The problem there is too much jerk (>10mm/min) causes awful results, too little jerk (6mm/min) results in blemishes.

I am in the process of putting together a video for @Phaedrux and anyone else kind enough to assist with diagnostics I may have to setup a YT account to do so.

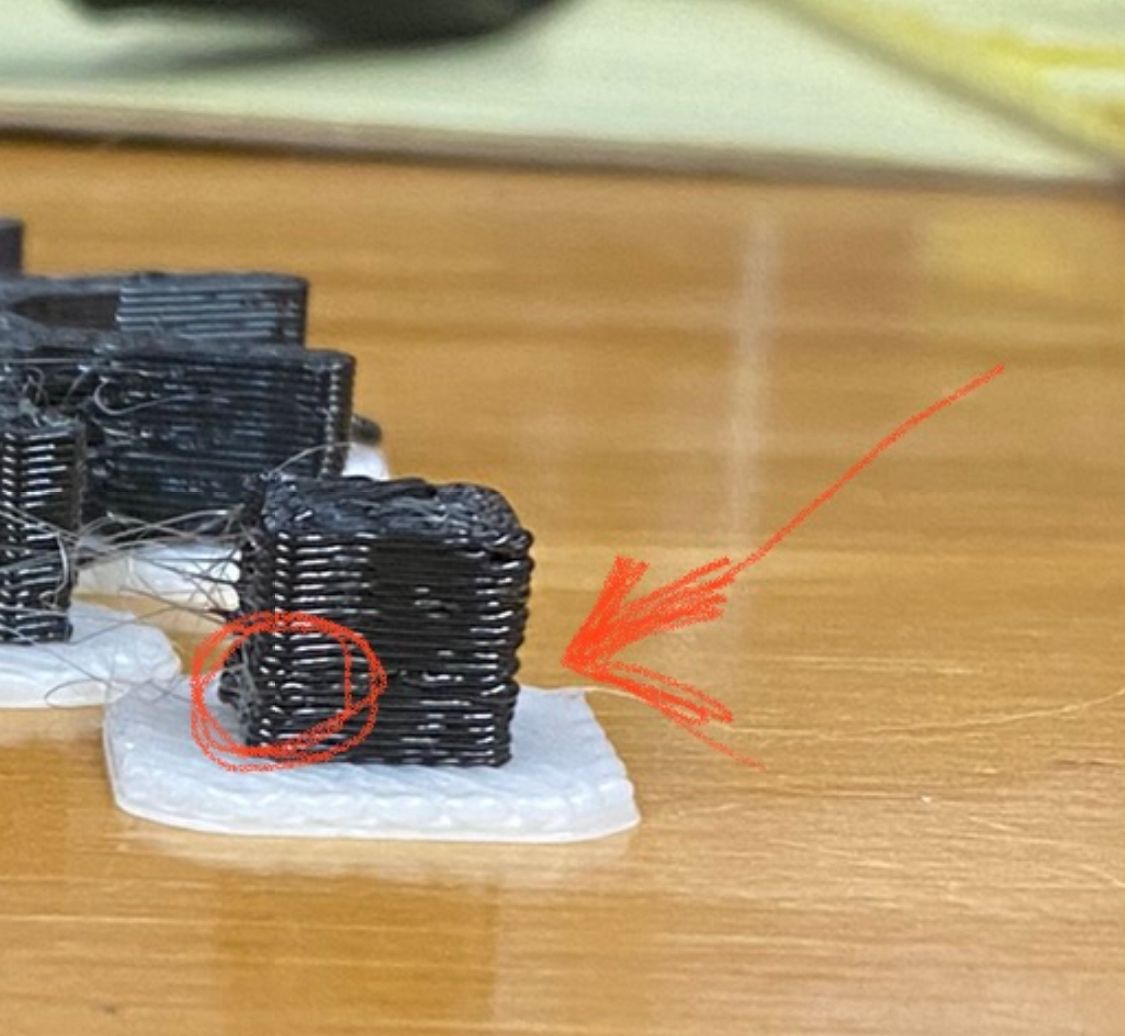

for the time being consider the images below of the part that will be featured in the video.

along with this synopsis:

The brim, raft and first 3 layers print on desirably (this has been typical.) Once the bottom solid layers finish the layers begin to shift little by little (in the magnitude of a fraction of a mm per layer).

I pause the print, home the toolhead, and resume the print and the next layer is nearly a cm off course.

I pause the print, home all, send some gcode that set the accelerations to 400 from 600, and jerk settings from 16 to 6. resume the print and we are back on target. I let the print finish using those low parameters and it seems to be okay.

Where the part has stringing and filament webbing out is when the accelerations and/or jerk caused the machine to not know where that tool head is located. I conclude that because when i update jerk and acceleration the and reset the toolhead it printed desirably.

Where i have circled showed the gradual start of the layer shifting. -

I wasn't able to find any info on the Aon M1, just the M2. But from what I saw it looks like a big machine. I would be surprised if the motors used such a low current but I guess if the expected speeds were very low maybe that is the case.

Does the mechanism itself move smoothly by hand (if that's even possible)

It's hard to see a layer shift with such rotund layers, but if you say so.

-

@Phaedrux Consider these examples. I have a box full of dozens of similar layer shifting for different part files too. In the example above I recognized it begin the slow shifting process and stopped it once I was convinced enough. I understand it is difficult to see but it was beginning to shift.

-

@Phaedrux said in Jerk Control M566:

I wasn't able to find any info on the Aon M1, just the M2. But from what I saw it looks like a big machine. I would be surprised if the motors used such a low current but I guess if the expected speeds were very low maybe that is the case.

Does the mechanism itself move smoothly by hand (if that's even possible)

if the motors are disabled they move pretty freely. If they are idle you can budge them provided you give a little extra force to do so. I imagine since the extruder motors are 1.3mA that the other ones driving the lead screws and belts are even higher rated that the extruders. I have a suspicion that my current ratings are low. I still have that in the back of my mind. Hopefully Aon will return my call or email back with some info regarding their legacy M1 model.

-

That's a much clearer view of the shift for sure.

@kroybal said in Jerk Control M566:

I have a suspicion that my current ratings are low. I still have that in the back of my mind.

I suspect that as well. What current value did you get up to in your testing and what was the motor temp? The motors themselves are water cooled? I would continue experimenting with higher currents.

-

@Phaedrux They're at 1.1A now, with water cooling they have a temperature of 45-50C in a chamber set to 40C. The extruder's motor ID was exposed so i found it to be 1.3A exactly. I got the rating set for 80%.

Today's work day is almost to an end so tomorrow I plan on doing a few things. Getting those currents up a little higher and monitor their temperatures, and perhaps swapping left and right tool head's roles between primary and support extruder. I have observed that the right tool head prints noticeably smoother than the left. by swapping roles I can see if the results are any different, if they are I suspect a bad motor. also I don't know if i have mentioned this at all but the shifting is exclusively in the X-direction.

anyways,

cheers!more to come tomorrow.

-

also which material are you printing and at what temp? are they "fresh" or they come with the machine? Humidity of the filament is really important

-

@MikeS We have worked primarily with ABS, we have fresh filaments as well. We keep a desiccant barrel in the shop where we store our filaments that are in use. Otherwise we store them in large bins. If we use CF Nylon we dry it in the oven at a low temperature the day prior and keep it in desiccant until use.

-

so the only remaining thing is mechanical...as suggested by other usually a nema17 is rated at 2A so i won't be scared to get current up to 1.5A (keep the temperature controlled 40/50° wouldn't scare me)..also please try some normal jerk values in the range of hundreds, i'm really shocked by how low you are trying to run your machine, i would stop a lot earlier and thinked about a mechanical problem before trying so mucj low jerk. Also consider that it is expressed in mm/min and not mm/s as other firmware (marlin for example) so it's normal value is 60 times the one you may be used to.

-

@MikeS said in Jerk Control M566:

so the only remaining thing is mechanical...as suggested by other usually a nema17 is rated at 2A so i won't be scared to get current up to 1.5A (keep the temperature controlled 40/50° wouldn't scare me)..

I have my current up to 1.5A which has been good no signs of over heating and my IR temp gun says 45C tops and mind you we're working with a 40C enclosed hot chamber. Until AON returns my call or email I will probably leave it around this configuration, however, I think I could even get some more power sent to the motors... more on that later.

also please try some normal jerk values in the range of hundreds, i'm really shocked by how low you are trying to run your machine, i would stop a lot earlier and thinked about a mechanical problem before trying so mucj low jerk. Also consider that it is expressed in mm/min and not mm/s as other firmware (marlin for example) so it's normal value is 60 times the one you may be used to.

Results have been inconclusive. I tried printing with jerk set to 60 (ten times my previous amount) and we got a some tower of pisa action. Ran the same gcode with jerk set to 6 again and we got a desirable print, it printed quite straight with the lower jerk parameter. Here is where it gets inconclusive though, I printed a different gcode of a different model using the settings that just worked before and we were back to the tower of pisa once again.

Out of curiosity, could my M360 micro stepping interpolation of 1/16 have any adverse effects causing the machine to lose track of position?

-

@kroybal said in Jerk Control M566:

Out of curiosity, could my M360 micro stepping interpolation of 1/16 have any adverse effects causing the machine to lose track of position?

Not really, no.

Can you speculate on the weight of the print head carriage?

If 1.5A is still no signs of overheating I would try to raise it some more. The Duet 2 is good to 2A with cooling on the drivers.

-

Id say >4kg

Approximately 2kg of motors, 1.5-2kg of wire chains, 300g of metal components, 300g of printed components, and however much a 20mm aluminum extrusion bar of 1m length would weigh. Neglecting fasteners, switches and belts.A more detailed description for those that are curious:

I got an aluminum extrusion bar approximately a meter long.With two cloned print heads each with:

two motors (by inspection 40x40x40mm), a large wire chain, four water cooling tubes, all resting on a flat aluminum plate (by inspection 60x120x5 mm) and a variety of idlers, hob gears, 3D printed housing and strapping components.The gantry itself has two more (smaller) wire chains that gotta add up to be at least a 500g, and two hot end brushes. The gantry is closed loop belt driven by two mirrored motors (40x40x60 mm) but does not bare their weight.

-

At this point, too much jerk produced bad results and too little jerk also did the same. Layer shifting has found its way through many diagnostics and proposed solutions. Could we be dealing with a faulty motor encoder? The problem is I got 4 motors driving the gantry, so which If any could be bad? The shifting is exclusively along the x axis either + or - direction so I reduced it down to x motors. I have tried isolating the motor issue by swapping roles of left and right tools from primary and support but the failures were consistent as before.

Someone else in the shop asked, could it be the file upload via the ethernet?

Personally I don't think so.

I am just so hung up over jerk settings because any time I adjust it I can observe changes in print quality. In some past cases I could print a quality part with one model, but layer shift with another holding my settings constant.

-

Yes that is a lot of weight. So I'm not surprised there is some skips with higher jerks. It makes the super low motor currents all the more suspicious. I would have imagined some rather beefy NEMA17s or even NEMA23s with that much heft to move around. It really seems like your motors just don't have the torque.

To get decent quality we simply have to get it up to a minimum jerk level otherwise the facets will be exaggerated. I would try lowering your acceleration a bit, maybe to M201 X300 Y300 and bump the jerk up a bit to M566 X100 Y100 and try for 2A of current. That's as high as you can easily go with the Duet anyway.

@kroybal said in Jerk Control M566:

Could we be dealing with a faulty motor encoder?

You mentioned closed loop belt, but are the motors closed loop as well? It's really too bad we're so in the dark about what the motors actually are.

@kroybal said in Jerk Control M566:

Someone else in the shop asked, could it be the file upload via the ethernet?

As in, could the file be corrupted? Highly unlikely. If it was you'd likely get bad command errors. Anyway, the CRC check on upload should catch it. But you can download the file again and run a compare on it against the original file from your PC as a check.

-

@kroybal for this weight i also exprected at least nema23 motors, also the frame should be really rigid to get decent print speed/time. Seeing that it is a professional commercial printer i won't say that requirements are not met and also you should really come in contact with the manufacturer to, at least, get the basic configuration they use for this machine. Anyway i wouldn't be surprise if the motors are really bigger than nema17 and current is too low. Let us know when the manufacturer answer you and if they help you fix the problem

Last thing i would check is that all the slicer speed/acceleration override are turned off...some slicer can modify the speed/acceleration based on feature type so it could overwrite your settings in config.g

-

@MikeS said in Jerk Control M566:

Seeing that it is a professional commercial printer i won't say that requirements are not met and also you should really come in contact with the manufacturer to, at least, get the basic configuration they use for this machine.

Well I got a hold of Aon finally, apparently they're updating their calling system. Anyways, the support team said that the M1 model is mostly a prototype for proof of concept. There are issues with the model, and there are success stories with it as well. They lined me up to talk to the machine's designer so I can get some answers on its anatomy. The support agent does not know a whole lot about their legacy machine, but she does know that the set screws used to tension the toolhead to the belt wiggle loose over time and that was one of the design updates they did going into the M2 model. That said I'm going to tighten screws where I can and see if they help control it from shifting. But based on the nature of the shifts it doesn't stand out as being mechanical slipping as much as it could be configuration.

We'll see. I am just happy to have talked to an Aon team member.

-

@kroybal Nice! let us know if you get it printing and show us some results

-

@bot said in Jerk Control M566:

I've noticed that with very low "jerk" rates, the facets of the model are much more visible. This is likely due to the extrudate "bulging" as the print head slows down to the jerk rate. In the case of OP, this is 0.1 mm/sec.

At low jerk rates the slow down and speed up will cause over- followed by under-extrusion at those points if not compensated by pressure advance, hence bulging at the intersections of the facets. Thinking about it, this could be a good way to tune pressure advance.

-

UPDATE:

Still playing phone tag with AON to no avail... they will cave soon and return my call.

Something that slipped through the cracks for many of us and especially me is my driver assignments on my config.g (listed above). The problem is that my x-axis steppers are on my toolboard LC the key term here is LC.

When I began the process of doing what could be the first ever duet powered M1 I did several iterations in wiring and driver assignments.

I have a PT100 daughterboard which is bound to the MB6HC, which also binds my extruders (1.3A rated motors) too.

@kroybal said in Hotend heater fault status:

This issue was resolved for those who experience a similar issue... I had my hotend heater mapped to a toolboard using pt100 sensors on the mainboard. Some rewiring and swapping pins around was in play.

This caused me to assign two of my axis steppers to the Toolboards kicking off my originally assigned extruders and hotends. I thought this was a solution

but I was overlooking LC. The idea was it would allow me to continue using my PT100's since this M1 machine prides itself on how hot it can get. But in turn it could be the basis of all my issues. All of my layer shifting has been solely in the x-axial directions.

but I was overlooking LC. The idea was it would allow me to continue using my PT100's since this M1 machine prides itself on how hot it can get. But in turn it could be the basis of all my issues. All of my layer shifting has been solely in the x-axial directions.I got assigned this board swap task after all the boards had been purchased. I was initially bummed that boss man didn't buy a 3HC Expansion board and now its coming to realization that my initial scoff at the toolboards might be valid.

I am still waiting on the motor specs for the machine... thoughts?