Mesh comp question

-

Hi,

Perhaps this will get you started:

https://duet3d.dozuki.com/Wiki/Using_the_manual_bed_levelling_assistant

Frederick

-

@fcwilt, I wondered if that wasn't what true leveling was but wasn't sure. I'll update my bed G and run it which is just an automated version of manual bed leveling ....Right?

-

@luckyflyer said in Mesh comp question:

@fcwilt, I wondered if that wasn't what true leveling was but wasn't sure. I'll update my bed G and run it which is just an automated version of manual bed leveling ....Right?

If you only have bed leveling "thumb screws" then you would use the Manual Bed Leveling Assistant (MBLA).

If you have 2, 3 or 4 independently driven Z steppers you can use Auto Bed Leveling (ABL).

They both use bed.g to probe the bed at different points to determine the needed adjustments to level the bed but MBLA tells you how much to turn each "thumb screw" whereas ABL drives the Z steppers as needed.

Frederick

-

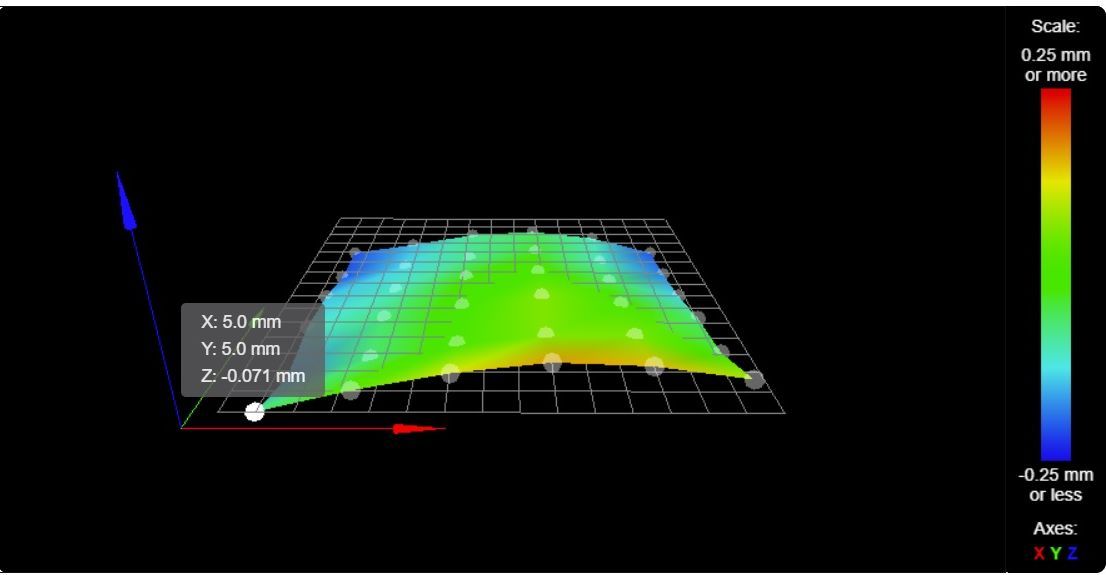

I've ran mbla and finished with the 3 bed points within .01 mm of the master 0,0. I reset the Z height. ran another G29. I had 2 5mm spires on the left side of the h.m for some reason so I reduced the probe points and got this height map.

Question can you tell from a height map if the printer will have trouble in a certain area? It seems to me that sometimes the mesh is not compensating to the level that it should for a good first layer in some areas of the print bed. With no probe offsets there should be no skewing of the map vs actual position.

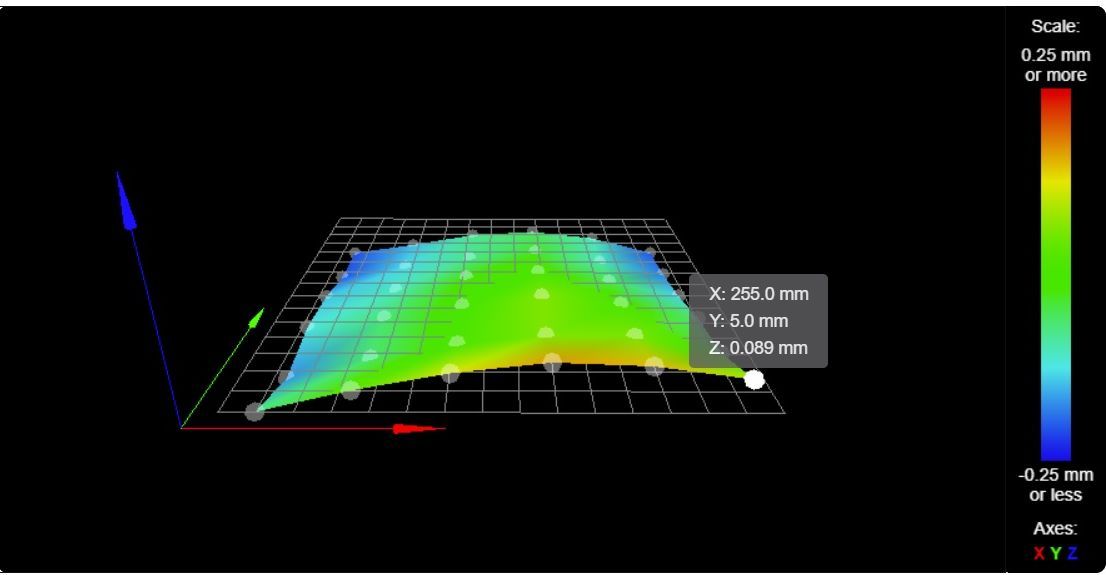

Also I don't understand why the area over the three adjusting screws have such different heights in the heightmap after an mbla. I'm able to probe over all three adjusting screws during a G29. The front left is -.071, front right is +.089 and rear center is somewhere between -.055 and -.079 on the h.m. when the mbla just a few minutes before said the three were within .01 of each other. I could understand if they were above or below the grid but all three should read the same.Wouldn't it be better to home Z at X,Y 0,0 where the master adjust screw is and then adjust bed screws 2 and 3 using the height map to zero them out?

Height map after mbla, G92 Z0 and G29

-

You likely already know this but I will mention it just to be sure:

It's essential to set the Z=0 datum using a single G30 at certain times. And when you do you must always use the same XY point - I use the center of the bed.

- after using G32 to run the Manual Bed Leveling Assistant or Auto Bed Leveling

- when using G29 to create the Height Map needed for using Mesh Compensation - it also enables Mesh Compensation

- when using G29 S1 to load an existing Height Map to enable Mesh Compensation

Moving on...

When using G30 you could use a XY point other than bed center but it isn't going to make any real difference when it comes to actually printing things.

Your height map suggests to me the X gantry is sagging as it moves through the center of it's range. It's possible your bed is shaped like that but I don't think it as likely as X gantry sagging.

BUT you mention using G92 Z0 which is not correct unless you have some specific reason for doing so. If you aren't already doing so you should instead be using G30 to set the Z=0 datum as mentioned above.

Frederick

-

@fcwilt

That is good to know. I used G92 Z0 because that is what is used in the "calibrate the Z probe trigger height" documentation here, https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

Is there an accepted procedure for checking the gantry while on the printer? I have a straight edge but realise that their true straightness can be questionable. Is there a step by step troubleshooting guide out there somewhere that addresses the issues that I'm having? -

@luckyflyer said in Mesh comp question:

That is good to know. I used G92 Z0 because that is what is used in the "calibrate the Z probe trigger height" documentation here, https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

G92 Z0 tells the firmware that the current Z position (whatever it may be) is 0 - which of course it may not be.

G30 sets the current Z position value to the Z probe trigger height. If the probe trigger height value is correct then the current Z position value is correct - which is why doing G30 at the specified times is essential.

Is there an accepted procedure for checking the gantry while on the printer? I have a straight edge but realise that their true straightness can be questionable. Is there a step by step troubleshooting guide out there somewhere that addresses the issues that I'm having?

I don't know. Because I knew it could happen when I designed my current printer the two X axis linear guides are mounted on the top and bottom of a 20 x 40 extrusion. The X axis range is 300 mm and there is no discernible sag.

Frederick

-

@fcwilt Thanks for your help and advise. I'm now over on the RepRap forum looking for methods for truing core xy mechanics.

-

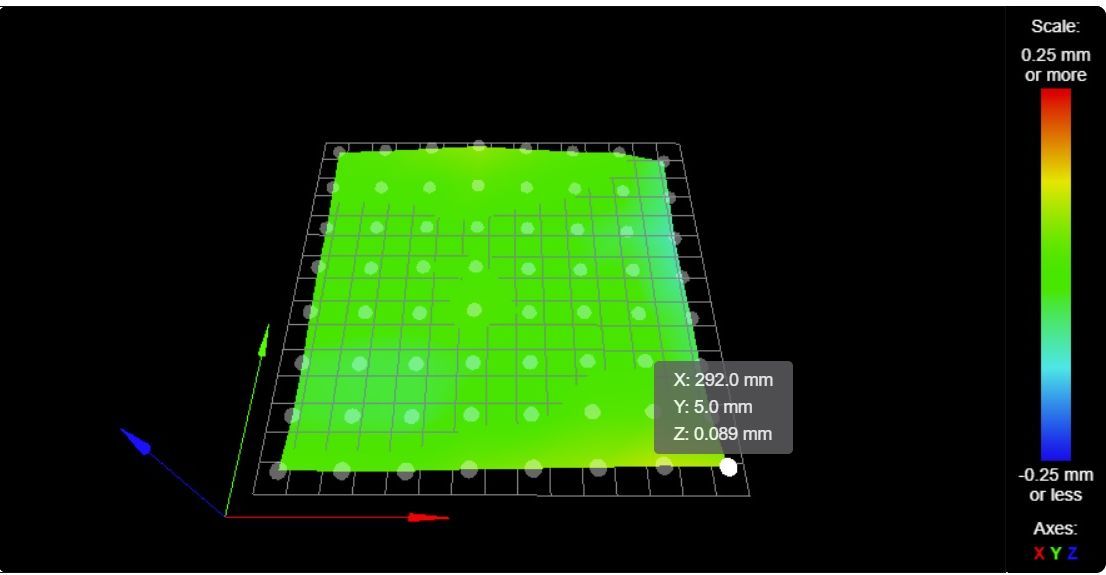

With a little tweaking this is what I now have. Hopefully this will make consistent prints anywhere on the bed.

-

That looks very good. All should be well.

Frederick