Nozzle rams into bed when not near center

-

@Phaedrux said in Nozzle rams into bed when not near center:

Cura start gcode?

G32 ; auto-calibration G21 ; metric values G90 ; absolute positioning M107 ; start with the fan off G92 E0 ; zero the extruded length G1 F4000 E3 ; extrude 3mm of feed stock G92 E0 ; zero the extruded length again G1 F{speed_travel} -

Thanks. I'm not a delta user, so I can't really see anything that is obvious to my eyes, but at least we now have all your relevant files posted so someone with a better feel for deltas might spot something off.

-

Contrary to many (most?) other duet (+ smart effector) delta users, I do NOT include G32 in my slicer's start gcode. I've found that, depending on the filament in use, the bit of ooze from the nozzle can impact the calibration negatively.

What I typically do is, whenever I change the filament to something that requires different heating parameters, I heat the bed and plate to what new filament requires, clean the nozzle (cleaning filament, then wire brush the nozzle until there's no oozing whatsoever) and manually run G32 a few times until the deviation values are consistent, and then save that to config-override.g (via M500.)

(I have the re-running of G32 automated via conditional gcode, but it's best to do everything manually until you understand what's going on.)

Then in my slicer config, I use G28 (to just home the printer) before it starts printing.

-

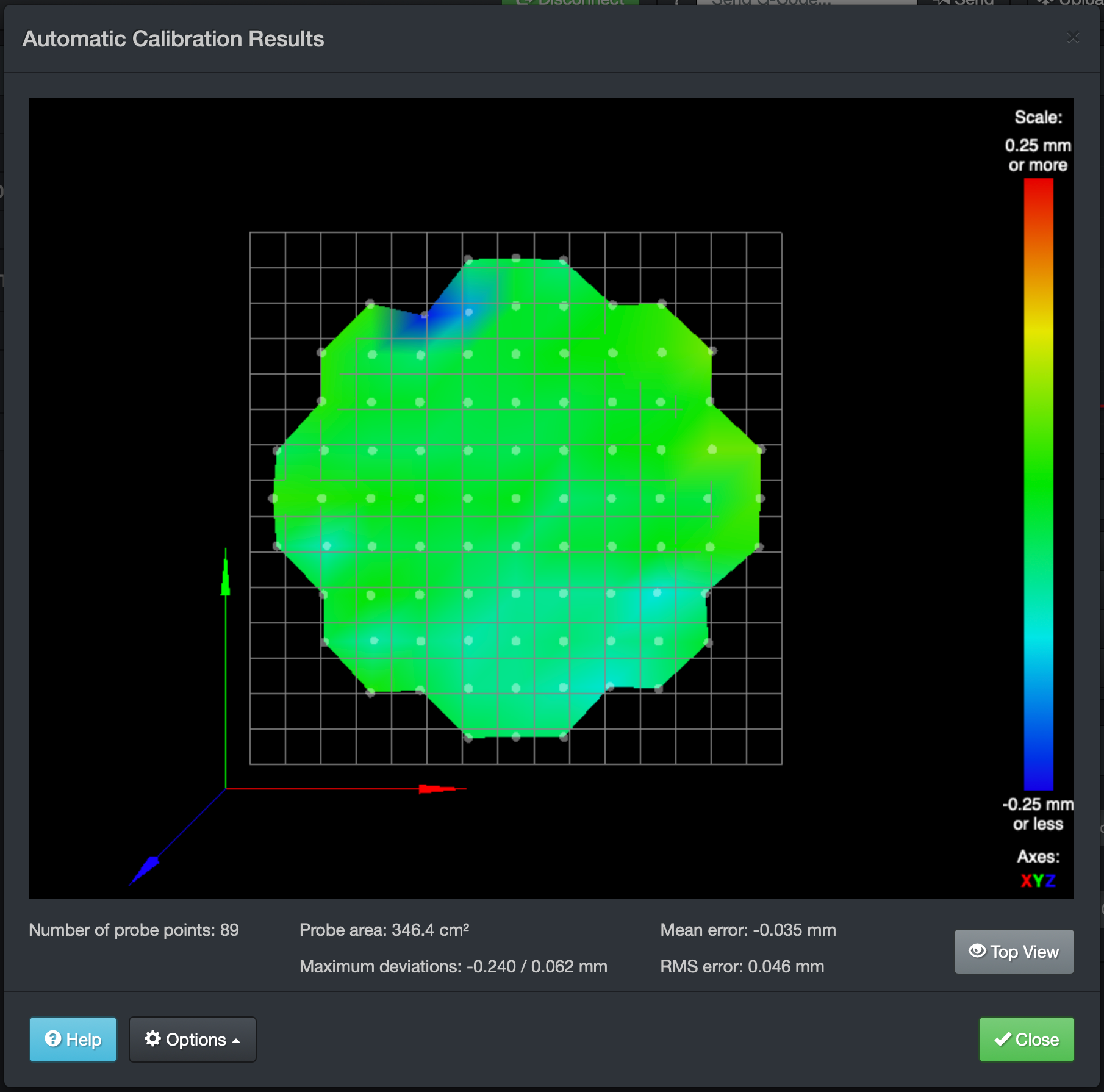

@deltwalrus, please run G29 after auto calibration and shown us the resulting height map.

-

G29 89 points probed, min error -0.240, max error 0.062, mean -0.035, deviation 0.046 -

the picture please

-

Sorry about that.

-

did you use M500 to save the calibration or did you put the values in config.g?

-

I did not run an M500 immediately after running the mesh grid compensation, no. I wasn't aware that was necessary, I figured it stored that information automatically after it ran. Thanks for the tip on that.

I will run another auto-calibration, then another mesh bed compensation routine, then I will run an M500 and try the print again.

As a side note, is there ever an instance where you would not want to store the results of a calibration or mesh bed routine? Shouldn't that be done automatically (in a macro maybe)?

-

No change in behaviour after running calibration, G29, M500, then starting print. Nozzle hits the bed near the "top left" part of the print, starts to actually rotate the glass bed with it, and even managed to dislodge one of the magnetic arms from the ball before the emergency stop halted the motion and reset the board.

-

This post is deleted! -

@deltwalrus said in Nozzle rams into bed when not near center:

I figured it stored that information automatically after it ran.

It does, but only while the printer is powered on. The values are lost after a power cycle unless they are either saved to config-override.g with M500 and adding M501 to the end of config.g to load it. Or manually copying the resulting calibration command into config.g

-

@deltwalrus said in Nozzle rams into bed when not near center:

I did not run an M500 immediately after running the mesh grid compensation, no. I wasn't aware that was necessary, I figured it stored that information automatically after it ran. Thanks for the tip on that.

G32 not G29.

-

I just got the new mirrors today, will test them for thermal suitability then give the problematic print another go.

-

It appears either my old glass plate was warped, or in the process of removing it and installing the mirror I fixed this issue, because a larger print is going right now and the bed ramming seems to be resolved.

Go figure.