Error: bad Command XXX W/RRF 3.2 and leveling issue

-

@3DPrintingWorld I am remote to the printer

IT is in the shop and I am at home and I am afraid to test it on the camera

IT is in the shop and I am at home and I am afraid to test it on the camera -

@martin7404 To be safe you could change it to a negative on the T1 offset then add 2.55mm to your T0 probe offset.

-

@3DPrintingWorld I am printing it now with 5 mm offset from the slicer

-

@martin7404 Got it! You are doing it differently but I just wanted to clear up what I said, to add to the probe height you would actually have to subtract.

-

YES and I canceled it , because slicer offset do not affect the priming

-

IT is working, showing 0.3 on the DWS screen. IT is in the air , but I can not tell from the camera

-

I did check one of my backups of the settings a month ago the offset for tool 1 was - and then testing it in manual with panel due I did switch it in some moment

-

@martin7404 That explains it!

Last night I erased the firmware a reloaded 3.1.1 and I still have all the same issues..... I must be missing something somewhere. -

V3.22 now it shows correct height but prints in the air.

Now testing with positive offset.

Installed 2nd camera as far I have to go home

One more thing on simulation it shows normal heights with positive offset and with printing shows layer+offset -

So made a few tests firmware 3.22

- Z offset -2.55 , the DWS shows exact layer height , but the head is about 5 mm up

- Z offset 2.55 and the head is about 5 mm up, and DWC shows layer height + offset

- Ofset iin config is 0 , Shows corect in DWC and the head is 2.55+layer up

Tested like that start printing and mid first layer EMERGENCY and measured with steel gauges.

I start to thing that this is a bug related to the fact it is IDEX definition in TOOLS section of config.g

-

Rollback to 3.11 and PANEL DUE to 1.24

Same story

With an offset of -2.55 on tool1 it is showing correct layer height and is about 5 mm up

Tried to disable the tool2 (copy mode in case this is messing), no efect I am starting to think, that because with + offset, shorter hotend than no tool, the duet has some failsafe no to hit the gantry. I will try to add 2.55 to probe and -2.55 to T0 ( loading TO with the config, of course ) -

It is working the - offset is in tool0 and tool1 have 0 offset, th probe ofset is now bigger

-

@martin7404 said in Error: bad Command XXX W/RRF 3.2 and leveling issue:

It is working the - offset is in tool0 and tool1 have 0 offset, th probe ofset is now bigger

I've been trying to follow along. Are you saying it's working as expected now?

-

yes

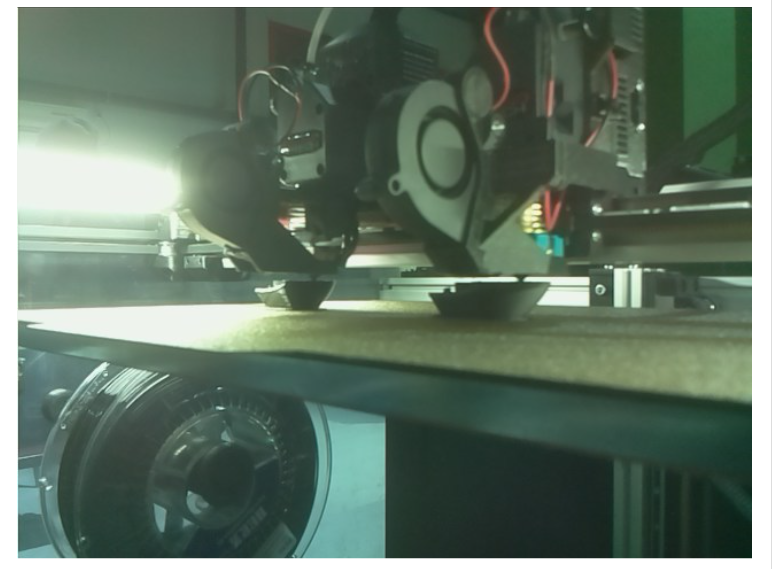

first print finished with tool1 (left)

here is my new config

It is with PRF3.11 and I think It will work with PRF3.22 tooG90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Muldex" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; X physical drive 0 goes backwards M569 P1 S0 ; Y right physical drive 1 goes backwards M569 P2 S1 ; Y left physical drive 2 goes forwards M569 P3 S1 ; U physical drive 3 goes forwards M569 P4 S1 ; E1 physical drive 4 goes backwards M569 P5 S1 ; Z left physical drive 5 goes backwards M569 P6 S1 ; Z center physical drive 6 goes backwards M569 P7 S0 ; Z right physical drive 7 goes forwards M569 P8 S1 ; E2 physical drive 8 goes forwards M584 X0 Y1:2 U3 Z5:6:7 E4:8 ; set drive mapping M350 X16 U16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X199.7 U200 Y199.8:199.8 Z799.2:799.2:799.2 E813.07:830.00 ; set steps per mm (1760nimble) M566 X1000.00 U1000.00 Y1000.00:1000.00 Z80.00:80.00:80.00 E100.00:100.00 ; set maximum instantaneous speed changes (mm/min)(Nimble 40) M203 X12000.00 U12000.00 Y12000.00:12000.00 Z1000.00:1000.00:1000.00 E4200.00:4200.00 ; set maximum speeds (mm/min) M201 X1310.00 U1310.00 Y1310.00:1310.00 Z35.00:35.00:35.00 E800.00:800.00 ; set accelerations (mm/s^2)(500)(Nimble 120) M906 X900 U900 Y900:900 Z900:900:900 E1000:1000 I30 ; set motor currents (mA) and motor idle factor in per cent(Nimble 500) M84 S120 ; Set idle timeout ; Axis Limits M208 X-18 Y0 U40 Z0 S1 ; set axis min - adjust X to align nozzle M208 X350 U422.7 Y333 Z300 S0 ; set axis max M669 K0 Y1:-1:0:1 ; select Markforged Kinematics Y to react with X and U ; Endstops M574 X1 S1 P"xstop" ;X axis active high endstop switch M574 Y2 S1 P"ystop+e1stop" ;Y Double max active high endstop switch ;M574 Y1 S4 ; configure sensorless endstop for low end on Y M574 U2 S1 P"e0stop" ;U axis active high endstop switch ;M574 Z2 S4 ;Stall Detection(no used) ;M574 Y1 S4 ; Y axis stall detection ;M915 P1:9 S3 F1 R0 ; Y axis stall detection ; Z-Probe M671 X-20.6:200:420.6 Y14.3:333.3:14.3 S10 ; Locations left, center, right M950 S0 C"duex.e6heat" ; create servo pin 0 for BLTouch M558 P9 C"zprobe.in+zprobe.mod" H10 F600 A1 T12000 ; set Z probe type to bltouch and the dive height + speeds G31 P25 X-29 Y0 Z3.97 ; set Z probe trigger value, offset and trigger height(lower number farther away)1.8build 1.7glass M557 X10:320 Y20:290 S60 ; probe from X=10 to 390, Y=10 to 290mm with a mesh spacing of 20mm ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4534 C9.565227e-8 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C0 R4700 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C0 R4700 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M143 H2 S280 ; set temperature limit for heater 2 to 280C M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F3 C"duex.fan8" Q500 ; create fan 3 on pin duex.fan8 and set its frequency M106 P3 S1 H2 T45 ; set fan 3 value. Thermostatic control is turned on ; LEDs M950 F4 C"duex.fan6" ;Q500 ; create LED 4 on pin duex.fan6 and set its frequency M106 P4 S128 H-1 ; set LED 4 value. Thermostatic control is turned OFF M950 F5 C"duex.fan7" ;Q500 ; create LED 5 on pin duex.fan7 and set its frequency M106 P5 S128 H-1 ; set LED 5 value. Thermostatic control is turned OFF ; Tools M563 P0 D0 H1 F0 S"Left" ; define tool 0 Left G10 P0 X0 Y0 Z-2.55 ; set tool 0 axis offsets y was .45 G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 X3 F2 S"Right" ; define tool 1 Right G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets - adjust Y to alignn nozzle G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ;M563 P2 D0:1 H1:2 X0:3 F0:2 S"Copy" ; define tool 2 Copy ;G10 P2 X90 Y0 U-90 S0 R0 ; set tool 2 axis offsets (WAS 105) ;M567 P2 E1:1 ;M568 P2 S1 ; turn on mixing for tool 2 ; set mix ratio 100% on both extruders ;G10 L1 P1 X0.0 Y0.0 Z-2.55 M501 ; Record M593 F66.6 T0 PO M575 P1 S1 B57600 ;Panel due ;G92 Z150 ;G91 ;G1 Z0.1 f100 ;G90

-

@martin7404 That is great news Martin!

-

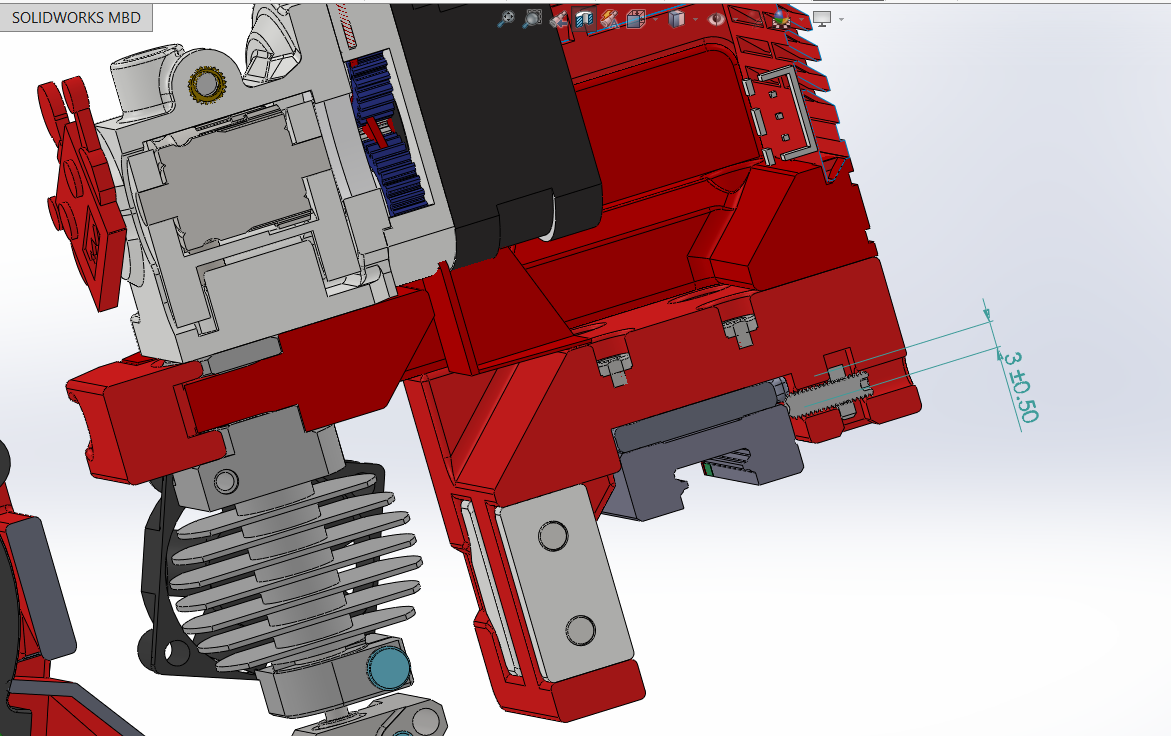

@3DPrintingWorld There is slight problem with such a diference 2.55 when the left head is near the Y0, so temp solution is to put a shim of 3 mm between the MGN9 block and the X cariage

-

So Put X carriage on 3mm plate and now both hot ends are aligned

-

@martin7404 I see your point. Good idea though, much easier then trying to move the other hotend down.

-

copy mode working

-

@martin7404 I'll have to look at the step file on the github. I dont think I looked at the file after I converted it. I did not realize that I had the Orbiter, it was supposed to have two BMG's.