Ender3 Linear rail conv. ghosting layershift bad layerlines

-

Hello,

I am helpless after building more than 12 printers by myself, but now

I have converted and Ender 3 with a Duet Wi-Fi board and linear guides,

and the print result are the worst and inconsistent of all my linear conversions incl. Two Tree Saphire s and ProWhat do I get, and have now idea why this happens:

See attached pictures for better understanding.- Inconsistent layer lines seems that extrusion changes around the perimeters changing from the bottom to the top

- one mayor layer shift at 10 cm

- Massive and worse ghosting ever seen on my prints

- Print settings same as on other printers is way higher nearly double of other printer

I have checked all the parameters that could come into consideration:

- all cables are attached properly no wiggle

- All belts are properly tensioned with metal spanners

- every single linear rail slider was cleaned, greased, and checked of smooth running before assembling and after assembling with tensioned belts on. There is now stick and slip or other factor that could lead to not running smooth in any position of xyz.

- nozzle and cooling system are attached perfectly tight and with no clearance or wiggle noticeable.

-I don’t understand the massive difference in print time. in Prusa slicer the only thing I changed was the printer tab all other parameters remained the same. The only difference is pressure advance, but can this lead to so much dramatic higher print times?

From all my prints it should lead to the best print result, but it doesn’t, and a don’t have any idea any more what could cause the inconsistent and bad print result in any discipline .

Last for the setup the extruder is a all metall with dual hobbet gears that should produce nice and consistant layer lines all over

In the following I will post pictures of the print results and the config.g that was used to print the part

I set the motor current to 800 as I found in the guide somewhere here set as default.

If I take higher values the motors sound very agressive and my fear was that this would cause wiggling arefacts on the surface. What are your defaults.Here no my config.g

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.9 on Sat Nov 28 2020 19:48:11 GMT+0100 (Mitteleuropäische Normalzeit); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Ender3ProDuetWifi" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; 3dp Extruder reverse physical drive 3 goes backward

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E131.00 ; set steps per mm E Basis 95

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X235 Y230 Z250 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure active-high endstop for low end on Z via BLTouch

;M574 Z1 S1 P"zstop" ; org configure active-high endstop for low end on Z via pin zstop; Z-Probe Achtung Reprap V3!

M558 P9 C"^zprobe.in" H5 F120 T6000 ; Set Z probe type to bltouch and the dive height + speeds

M950 S0 C"exp.heater7"G31 P500 X-40 Y-12 Z1.60 ; Set Z probe trigger value, offset and trigger height je gGROESSER desto NAEHER DRAN

M557 X35:235 Y35:200 S40 ; Define mesh grid S40 bedeutet die Grid-Messpunkte sind 40mm voneinenander entfernt

M671 X35:200:200:35 Y200:200:35:35 P0.5 ; point1 (35,200), point2 (200,200), point3 (200,35), point4 (35,35); Heaters

;M308 S0 P"bedtemp" Y"thermistor" T107600 B4183 R4700 ; configure sensor 0 as thermistor on pin bedtemp

;M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; Umbau Silikonheizbett NTC 3950 100kOhm configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

;M307 H0 B0 S1.00 ; diable bang-bang mode for the bed heater and set PWM limit "B1 is on"

M307 H0 P558.6 I136.699 D327.8 B0 S1.00 ; diable bang-bang mode for the bed heater and set PWM limit "B1 is on"

M140 H0 ; map heated bed to heater 0

M143 H0 S135 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 250C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H1 T45 ; set fan 2 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

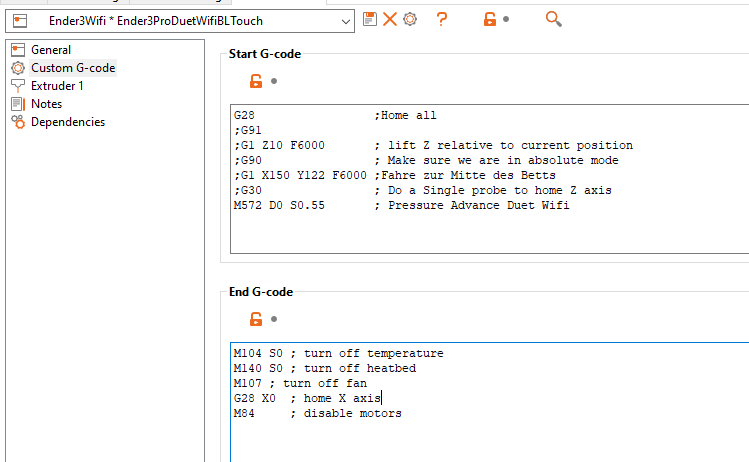

M575 P1 S1 B57600 ; enable support for PanelDueand the start gcodes of the Ender 3:

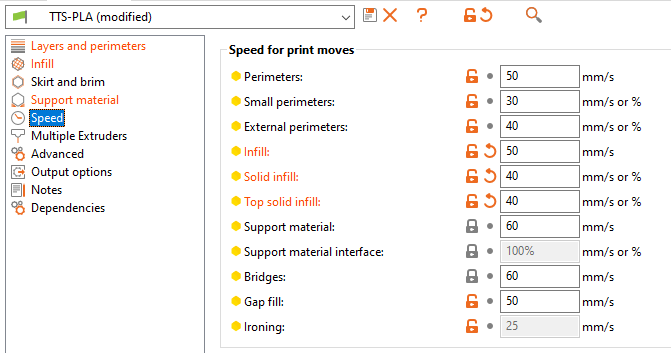

And as you can see my speed settings are, at least for my experiences low.

on the other machines I almost get no or hardly to see ghosting!So, if you have the same type of machine setup and experiences better results than me please help me out with your experiences especially

and

that is why I am asking here, are there settings in the config.g wrong so it can be responsible for the different bad print results.Thank you so much in advance

Regards -

can you resend your pictures as they didn't upload.

I run my ender 3 with the motor current set at 1200ma.

The stock motors are 1500ma and the typical rule for current is 80% of the maximum.Oh, and your hotend thermistor is wrong if you're running stock. It should be B4092

-

This post is deleted! -

Sorry for what ever reason you have to upload one picture at a time:

-

@jay_s_uk said in Ender3 Linear rail conv. ghosting layershift bad layerlines:

The stock motors are 1500ma and the typical rule for current is 80% of the maximum.

mine are 0.8A and match this description

https://gist.github.com/knoopx/e6c40a009e796203b93a75a3ed6a5ab8

-

I had it before to 1000mA but the layer shift occurred with 800mA.

I went down to 800mA beause of the harsh sound and the bad surface with 1000mA, in the hope of getting better surface to less current and therefore less rough motor management -

your bed seems massive compared to the original ender 3 bed.

did you change to a better y motor?

you can try

https://duet3d.dozuki.com/Wiki/Gcode#Section_M593_Configure_Dynamic_Acceleration_Adjustment -

Yes thanks the bed is a 6mm fine milled aluminium plate, but the layer shift occured in "X" direction.

The ghosting is on either direction the same, if the mass of the y axis would be the trouble maker it should be different ghosting in x and y .

as you clearly can see on the picture it seems to be the same in both direction.correct assumption?

M593 I will dig into it sounds very interesting, didnt recognize this before

Thank you very much for the valuable tip! -

@Veti here is the creality listing clearly showing the 42-34 motors are 1.5A https://creality3d.shop/products/creality-42-34-stepper-motor-with-round-shaft

-

From M593 documtentation:

High X and Y jerk values reduce the effectiveness of DAA; therefore you should set the X and Y jerk limits only as high as necessary to allow curves to be printed smoothly.

What are your jerk settings for a Ender3 linear conversion (disregarding my heavy bed)?

-

@jay_s_uk OK

I will up to 80%= 1.2A even of the harsh sound but this schould at least eliminate the layer shift

I will leave the question open if a high motor current can leave to a worser surface!

May be there is somebody out who can share explicit experiences about the relation ofmotor current =? harshness motorsound =? worser suface quality

-

on the noise front theres not that much you will be able to do due to the TMC2660's in the duet 2 not supporting stealthchop.

Some motors will be noisier than others.For the banding I would look at your belt paths to make sure you aren't running the toothed side on smooth rollers. Maybe look at belt tightness etc to make sure they aren't slack and go from there.

-

Good point !

I checked all the rolers on the belt tensioners and there are toothed rollers as it should be .

I double checked every axis if there isn't any rubbing or continous massive oscilation or vibration when I move the bed or the x-axis,Though you gave me a very important advise:

The rollers were correct but

what I found out by reducing the belt tension the oscilation of the bed and x-axis could be reduced to a very smooth movment farliy noticable belt drive any more.so conlcution: it seems that the belts where maybe too tight, but

they feel now so sluggish that I get probably other negativ effects.

If I titen them to my exprience like all my other printers the result is like shown,

on my other printers I do have the same pretention and I can feel the belt oscilating effect

of the teeth but get inspite of that perfect surfaces. -

little update

I have downloaded a jerk and acceleration test like teaching tech expalins

https://www.youtube.com/watch?v=Mnvj6xCzikM

and have just printed with 1200mA instead of 800mAsame strong belt tension as before (tested this after)

and at least with the testobject and in relation with what I see in his video my print looks pretty good better than in the video.

So as i directly cannot compare (for that I have to print the same housing again) its seems

that upping the amps has done a good job,

try to upload some images but a movie would be better!Is there anybody out there who can explain why upping the current my lead to this better

result of barly seing ghosting better and consistant layerthickness (but, the test body was only 1 permeter no infill( so there are other things to consider in a closesd filled body!? -

Seeing all this different situations out of the geometry I would like to see how every single situation and the ghosting in relation to cornering sharpness accelleration straightness speet fits into the shown results.

Thanks in advance,

will add the M593 faktor to the pre-gecode and see if there ist an improvement

-

so now after going through my other post Pressure advance and print time and adjusted all paramters so I now get reasonable results in print time but still getting ringing artefacts

arround corners AND on straight lines.

I strongly belive that the motor current produces a resonance!

Therfore I reduced Motor current to 1000mA again because I see at 80mm/s and have still resonance in the x and y directionadditional with no ringing compensation on, measured 3mm peak to peak an 80mm/s speed, so I applied 26,6 Hz

M593 F26.60 ; cancel ringing at perimeter 80mm/s/3mm=26,6, Hz Dynamic Acceleration Adjustment (DAA)

result: NO noticable enhancement and reduction auf oscillation (ringing) at all!

on all Axis still remaining the same 3mm the ringing is because of the heavier bed as expected more noticable on the x axis than vice versa,

any idea what still causes the ringing even if 593 applied?

-

@ProntoPrint said in Ender3 Linear rail conv. ghosting layershift bad layerlines:

any idea what still causes the ringing even if 593 applied?

DAA isn't perfect and can't correct for every cause of ringing. If there are multiple ringing frequencies for instance.

What speed, accell, and jerk values are you using?