Twin Extruder Motors - Push/Pull

-

Yes, this isnt clear to me. In the Gcode library it has as example of ;

M906 X300 Y500 Z200 E350:350

but then says;

Example: If you have two motors on your Z axis, physically connected to Z and E0 stepper drivers, configured with M584 Z2:3, set M906 Z200, not M906 Z200:200

So maybe your right these E & Z are treated differently. If so that's great because I could run a much bigger stepper on the frame with a higher current. I could run an M906 E500:1200 to drive these for example.

Does this however mean I have to add the other extruder setup lines such as M350, M92, M566, M203, M201?

I guess it would be good to get confirmation that M567 P0 E1:1 will do what I think and set extrusion rates of 100 on both motors and that I'm not barking up the wrong tree!

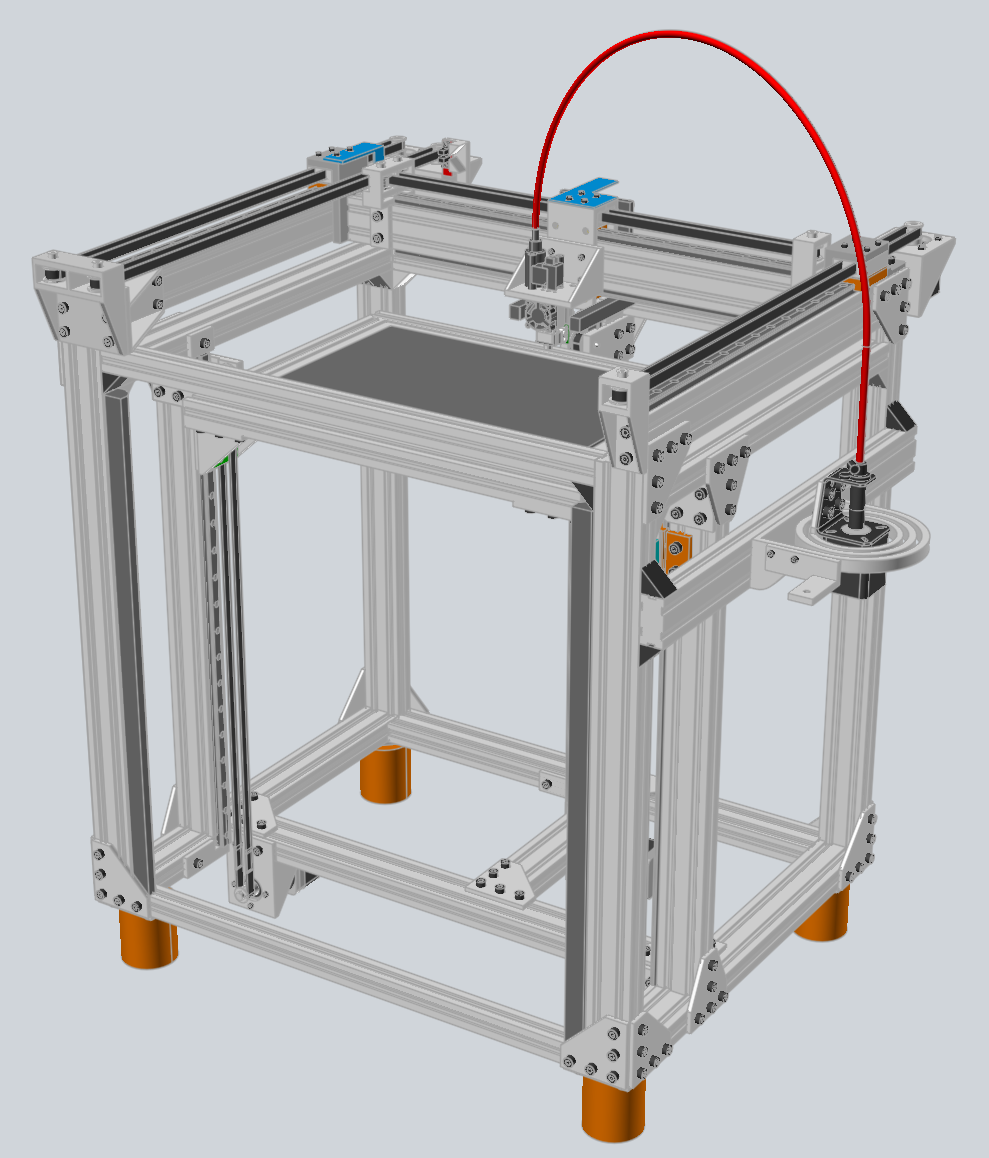

On the weight issue I am trying to have my cake and eat it, or at least have the best compromise I can find. I'm currently running water cooled to run high enclosure temps so Zesty or similar would cost me that ability. Perhaps I just need another printer for faster prototyping!

-

I am running a push pull system. I have my two motors in series they are both bondetech extruder drives with exactly the same ratio. I had tried hooking both drives to seperate drivers on the duetwifi and i used mixing extruder in my case 1:1 ratio it worked but amount of filament used on the DWC was way off basically if the part required 10 meters of filament dwc would say it had used 20 meters of filament. My suggestion to you is to use identical extruder drives with and hook them up in series...I keep the one closest to the extruder fairly tight and the push drive a bit on the loose side.....I have never had a problem with missmatch between the two drives....I have done prints in excess of 40hrs

-

You should try remote-direct extrusion. There are extruders available on thingiverse.

Or you make sure both motors/setup are exaclty the same and connect them in series (not parallel).and load some slack in between.

-

@percar said in Twin Extruder Motors - Push/Pull:

DWC was way off basically if the part required 10 meters of filament dwc would say it had used 20 meters of filament.

@chrishamm

I'm sure DWC calculates the extruded amount based on 1.75 filament?

If we could set it to a different diameter (50% cross section) it will calculate the right amount.

OTOH, it's just DWC showing false numbers, the printer shouldn't be affected. -

@o_lampe DWC does not calculate any extrusion amounts, it sends bare M83 and G1 Ennn Fmmm codes to RRF. If mixing is configured with uneven ratios (e.g. 100% for E0 and 100% for E1) DWC will get twice as much extrusion which is then summed up.

I guess it would be better if the firmware recognized extruders mounted in series and then treated them as such. I'll think about it.

-

@chrishamm said in Twin Extruder Motors - Push/Pull:

I guess it would be better if the firmware recognized extruders mounted in series and then treated them as such.

Thanks Chris, I thought about push/pull steppers when I saw that Prusa's MMU2 switches off the push-extruder, although there is so much filament-friction to overcome in that setup.

-

@dm86 It should work - and you aren't the first so it can be done.

You haven't mentioned what firmware version you are using. On earlier firmwares, it was necessary to also add M568 P0 S1 to enable mixing. That is redacted on later firmwares and M567 on it's own is sufficient.

If that doesn't work, try moving your M584 to before your M569 commands (I doubt that's the problem but worth a try).

If that doesn't work, post your entire config.g.

Oh, and you are sending a T0 command before you attempt to extrude yes? Or you have a T0 command in your config.g file yes?

-

@chrishamm

Could I set 50% extrusion ratios on both & half the steps per MM? -

@deckingman Thanks, really helpful.

Sorry I forgot to put it, beta3.2 at the moment on Duet2 wifi +Duex5.

Seeing as I don't understand the T0 reference, probably not! Sorry could you give any more detail on what I should be including there?

Will have another quick go today and then post full config.g if I don't get it working.

-

@percar Good to know I'm not on a dead end! I suspect your right and will end up with this config but would like to try and make use of my spare drivers if I can. I don't know if a second small motor will really help that much (plus I don't have an identical one to hand!)

-

@dm86 I wouldn't recommend that but it may work. I'll work out a solution in the firmware to address this limitation. The filament-based estimations should already remain correct regardless of the mixing ratios.

-

Excellent, thank you @chrishamm

As a quick update I now have it 'working', well everything moving as expected at least.

Fundamentally all that confused me was this line in the GCODE library;

If you have two motors on your Z axis, physically connected to Z and E0 stepper drivers, configured with M584 Z2:3, set M906 Z200, not M906 Z200:200

I incorrectly assumed this applied to extruder motors too, where in reality it seems it does not. Not sure who maintains this text but maybe worth adding an extra note in there to make that a little clearer. Although with hindsight the previous included example of M906 X300 Y500 Z200 E350:350 should have been a clue.

Once I went through and added all the other standard motor parameters everything started working. As my extruders are not totally identical (metal BMG clone on HE & OG one on frame) I'm going to calibrate both extruders individually and go for a test print. Will report back after a few prints.

Thanks all for your input

-

Just something i am wondering about:

Have you ever (or any one else) tested a double/series-extruder-setup with nimble? That would be 1 standard "before the tube"/"outside" (like a bowden) and the other one (nimble) right before the nozzle? Wonder if that would bring any improvement on reliability while also keeping the weight low... or would you say you are so happy with your nimbles that you think something like that is pointless? (Asking for a ptfe-tube-length of around 2 meters...)

-

@dm86 For info, and for future reference, extruders are treated as if each one is an individual axis. So multiple extruders can be mapped to a single tool using M563, but they are still individual "axes", so you have to set steps per mm, currents, acceleration, speeds, jerk etc etc etc, for every extruder.

-

@LB said in Twin Extruder Motors - Push/Pull:

Just something i am wondering about:

Have you ever (or any one else) tested a double/series-extruder-setup with nimble? That would be 1 standard "before the tube"/"outside" (like a bowden) and the other one (nimble) right before the nozzle? Wonder if that would bring any improvement on reliability while also keeping the weight low... or would you say you are so happy with your nimbles that you think something like that is pointless? (Asking for a ptfe-tube-length of around 2 meters...)

Well the intent of a remote drive extruder is to keep the stepper off the extruder assembly.

I am hoping the Zesty gets the v3 to market soon and it works as planned. I currently see no reason to not use a Nimble.

But others could not get it to work to their satisfaction and I don't know exactly why - perhaps they were trying to use v2 units.

Frederick

-

@LB

One thing I use with the Nimble that others have used is a gimbal to allow the stepper to move which reduces pressure from the drive cable on the extruder assembly.