Two different size stepper motors on y axis?

-

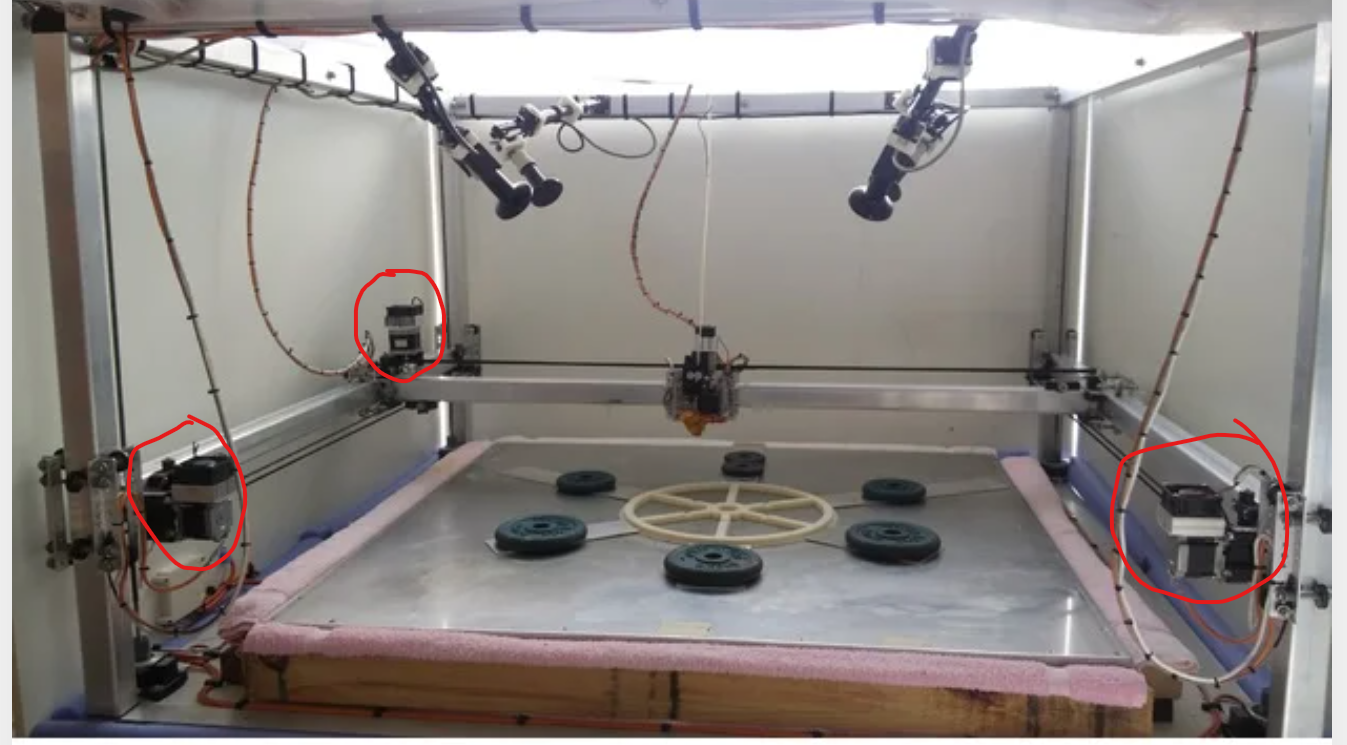

I'm planing to build large cartesian printer similar to the one on the picture with two nema23 motors for y axis.

As there is a 0.7kg x axis motor on the one side of the gantry, i'm wondering if it is a good idea to put a larger motor on that side as the mass for motor to move is significantly larger.

Each motor would have it's own stepper driver on Duet 3 board but i'm concerned that difference in motor size would cause different acceleration profiles that would be hard to synchronise.

-

@yrud RRF does not support different current settings for different motors on the same axis, even if on different drivers. From https://duet3d.dozuki.com/Wiki/Gcode#Section_M906_Set_motor_currents

RepRapFirmware does not support individual motor settings where an axis has multiple motors connected to different stepper drivers. The first parameter specified will be used for all motors on the axis. You should use identical motors on any axis that has more than one motor to avoid unexpected behaviour.

Example: If you have two motors on your Z axis, physically connected to Z and E0 stepper drivers, configured with M584 Z2:3, set M906 Z200, not M906 Z200:200It is generally recommended to use the same motor everywhere on each axis (because then the responses will be the same!)

Also, the acceleration of each motor on the axis will be the same, the only difference will be a small amount of lag between the motors (fraction of a microstep and almost certainly less than the flex in the belt). I'd hazard that that will be far below the other tolerances on the machine (guessing the moving mass is a few kg in total). The influence from whether your x carriage is at one end of the gantry or the other will be nearly as significant!If you're really worried, I'd recommend just adding a bit more mass to the right hand y-carriage to balance out the system (you could even test how much difference it makes)

-

@engikeneer Great response! Thank you.