Ask user to set bed temperature before bed mesh probing

-

@maxgyver or just take the heating command out of mesh.g. Then make a set of macros called e.g. mesh_probe_50deg etc, which heat the bed and call G29. Then all you have to do is click the right macro

You could even get them to save the heightmap with a specific name for the temperature so you can easily load it next time (and know what you've loaded!) -

Hey, thank you all for your feedback!

@nurgelrot said in Ask user to set bed temperature before bed mesh probing:

How about writing a conditional macro placed the start gcode in your slicer to load a low|medium|high heightmap based on printing temp?...

That's an awesome idea! I will give this a try.

-

@maxgyver said in Ask user to set bed temperature before bed mesh probing:

I noticed a "substantial" difference in the bend radius of my printbed depending on its temperature.

I was reviewing this topic and wanted to ask what you mean by "bend radius" and why it is related to bed temp.

Thanks.

Frederick

-

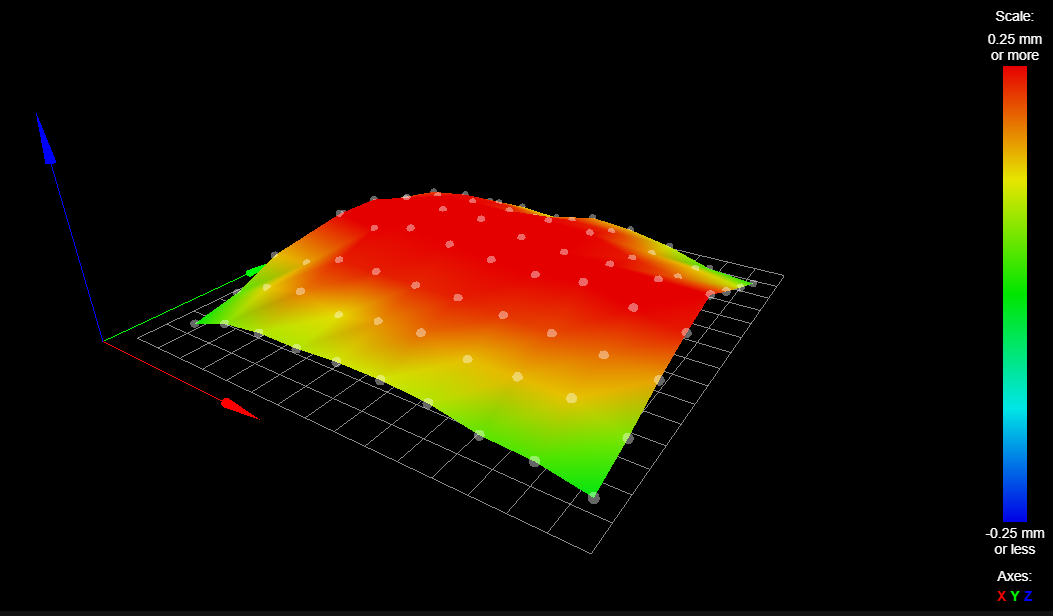

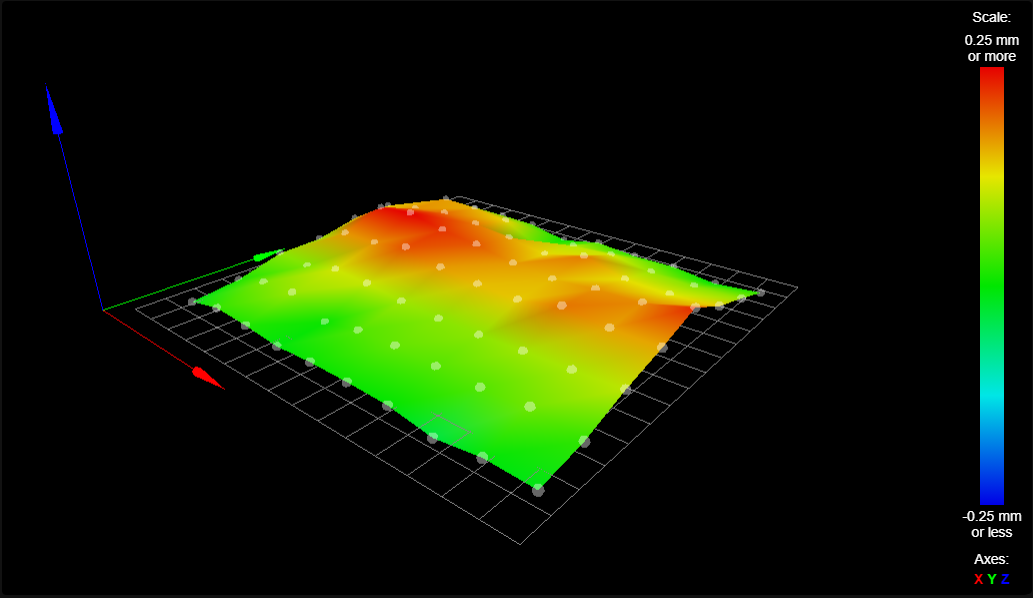

Maybe "bend radius" is the wrong word... I have a rectangular aluminum bed with a 1400W heater. Due to the heat expansion of the aluminum, the bed tends to deform. In my case it is "bend" along the X-Axis as can be seen on the hightmap.

-

@maxgyver said in Ask user to set bed temperature before bed mesh probing:

Maybe "bend radius" is the wrong word... I have a rectangular aluminum bed with a 1400W heater. Due to the heat expansion of the aluminum, the bed tends to deform. In my case it is "bend" along the X-Axis as can be seen on the hightmap.

Thanks.

Is your bed mounted in such a way that it can expand freely in any direction?

Frederick

-

@fcwilt

Yes, it is mounted on studs with silicone o-rings under the screw heads acting as thermal insulators and flexible washers. -

@maxgyver said in Ask user to set bed temperature before bed mesh probing:

@fcwilt

Yes, it is mounted on studs with silicone o-rings under the screw heads acting as thermal insulators and flexible washers.Are the holes larger than the studs by a few mm?

Thanks.

Frederick

-

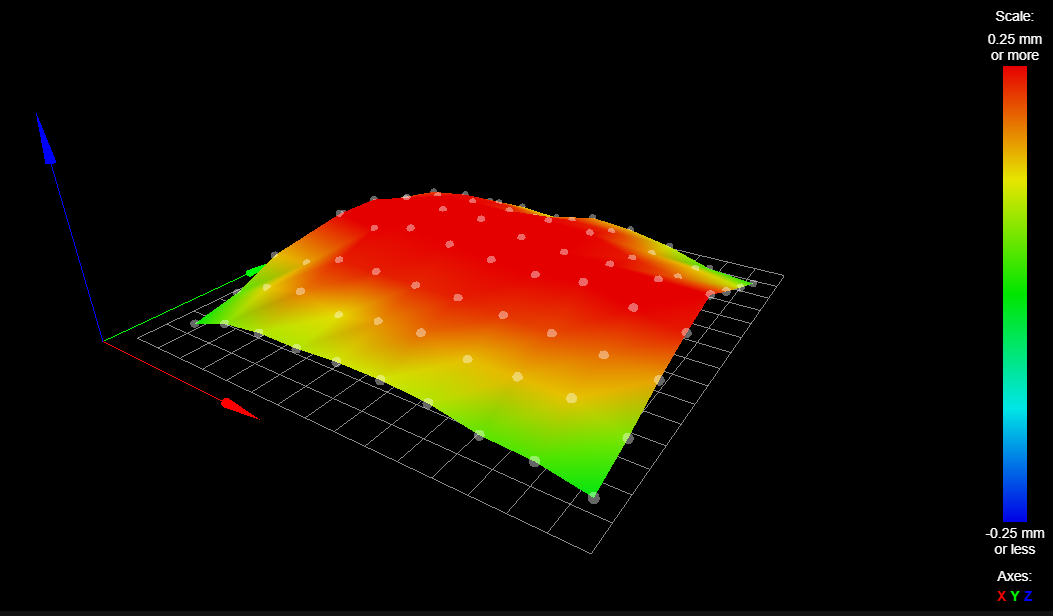

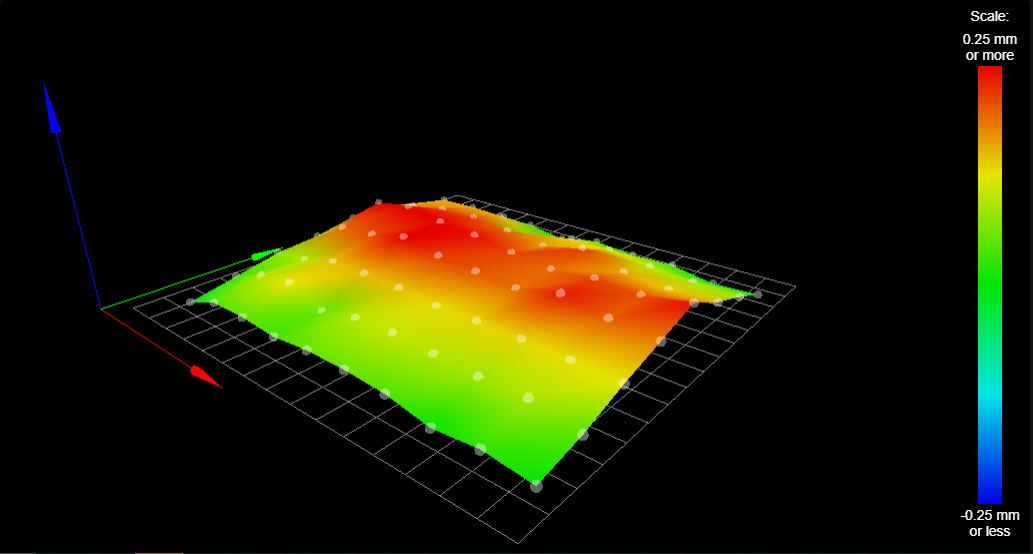

@fcwilt When I checked if the plate has some "wiggle" room, I noticed that the screws are clamping the bed quite hard. I loosened the screws a bit and made sure the bed can expand freely. To my surprise the hightmap looks much better now. I would not have thought that a 6mm aluminum plate will bend so easily.

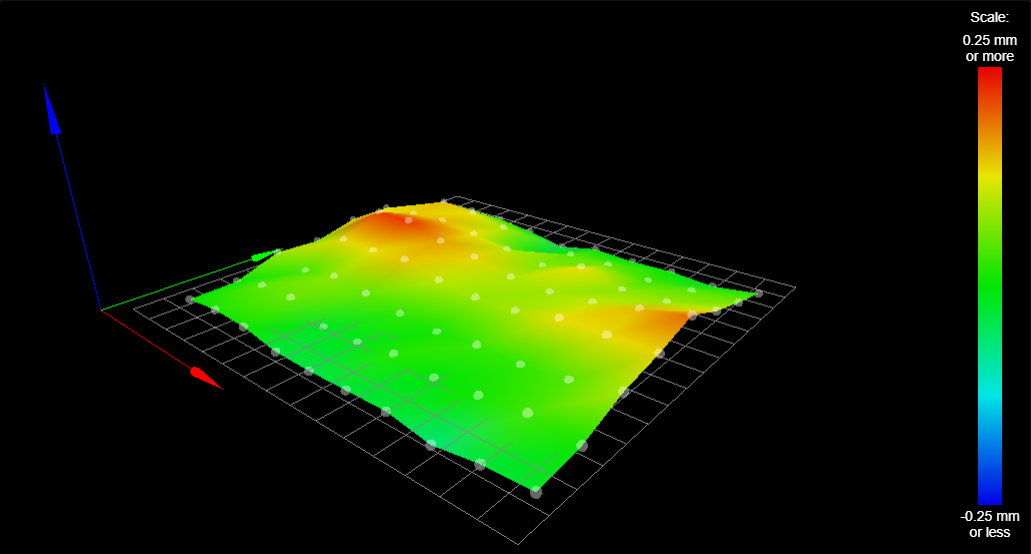

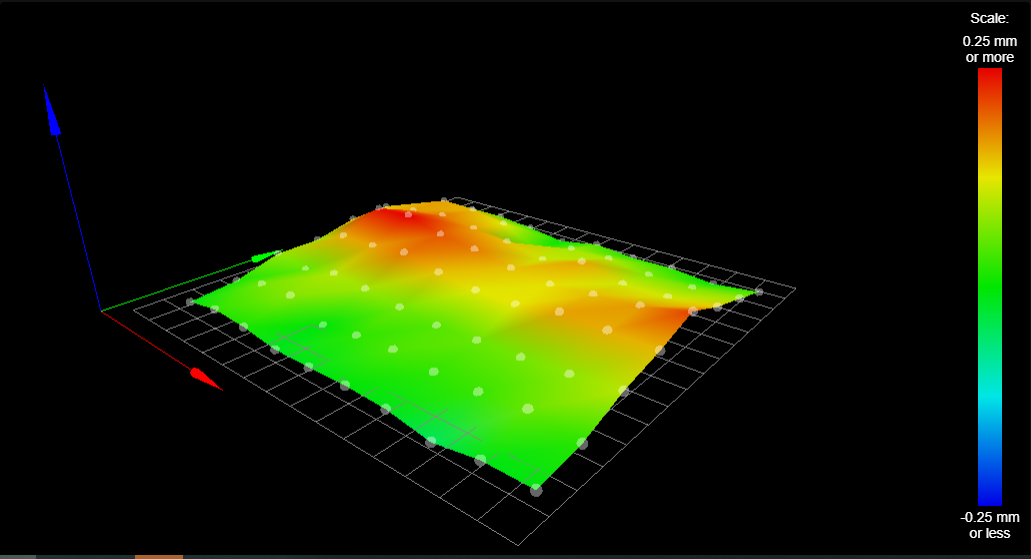

Anyway, I have extended my mesh probing routine to probe at room temperature, 60°C, 80°C and 100°C and save the height maps as separat files. I have also added a 60 second delay after every heating cycle to ensure the bed has an even temperature before proceeding with the next mesh probe.

Roomtemp

at 60°

at 80°

at 100°

-

And with this start Gcode for PrusaSlicer the correct heightmap is loaded according to the temperature of the printbed.

{if first_layer_bed_temperature[0] <=40} G29 S1 P"heightmap_roomtemp.csv" {elsif first_layer_bed_temperature[0] <=70} G29 S1 P"heightmap_60°.csv" {elsif first_layer_bed_temperature[0] <=90} G29 S1 P"heightmap_80°.csv" {elsif first_layer_bed_temperature[0] <=110} G29 S1 P"heightmap_100°.csv" {endif}Thanks everyone for your ideas and feedback. This is by far more elegant than my original idea.

-

You might be surprised how long it takes for a 6mm aluminum plate to stabilize.

You mentioned 60 seconds.

On my printer I wait at least 10 minutes - when starting from cold I wait 30 minutes.

You height maps look better - I suspected from the shape that the plate was encountering resistance to expanding.

It certainly doesn't hurt to have different height maps but they don't look that much different.

I will be interested to see if they make a difference for you.

Good work and good luck.

Frederick