Bed mesh correction and tool offsets...

-

@dc42 Oh, you were talking about another tilt axis with the chain thing, yea, that makes sense. I will re-probe my new bed (just on top of the old) so you get an idea of how bad the current bed really is.

-

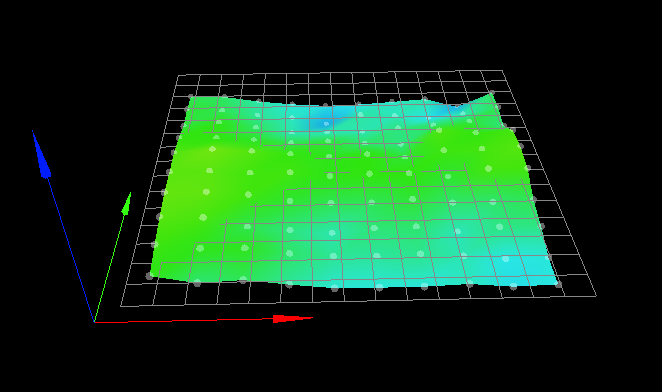

@dc42 Here's the "new" bed, I just slapped it on top of the existing bed, so likely this is not the best it will be eventually. The Z motion system will also be replace to be a kinematic coupling style so the bed can extend properly when heating.

I think it's safe to assume that the saddle shape does not arise from sag in the gantry, but rather from the bed itself.

I would really like to get this fixed though. It will easily take another month or so before I can actually use the new bed (missing hardware, printed parts that need actual printing etc)

-

If the adjustments to the z position with baby stepping are consistent based on XY location as you say, then you could potentially directly edit the heightmap.csv to alter the points to match reality.

-

@phaedrux Yea I guess technically that would be possible, but I have really no idea how one would do that in practice (finding the offset for each recorded csv value during a print).

I guess maybe one would have to print a grid or something very slowly and a turn at each probe point so it applies the new babystepping?Dunno, seems... complicated

-

@diamondback said in Bed mesh correction and tool offsets...:

Dunno, seems... complicated

Because it is.

Perhaps the best meaningful solution is to simply wait until you can replace the current bed with something better.

Frederick

-

@fcwilt Hm... While an option, I don't feel this is the correct option here...

This bed worked fine, so it's not like RRF can't deal with it. I really feel like some place is using the wrong tool offsets... -

@diamondback said in Bed mesh correction and tool offsets...:

M208 X-146:159 Y{global.minY}:{global.maxY} C0:250 Z0:290 ; set axis minima & maxima

Can you check that anywhere you have variables and conditional code that it evaluated correctly?

You can send M208 M577 etc by themselves in the gcode console and it will report what the current value is.

-

@phaedrux Will do, however, these globals are a super recent addition and the issue way predates this specific mesh setup.

-

@diamondback said in Bed mesh correction and tool offsets...:

@fcwilt Hm... While an option, I don't feel this is the correct option here...

This bed worked fine, so it's not like RRF can't deal with it. I really feel like some place is using the wrong tool offsets...Do you really want to print on a Pringle?

Frederick

-

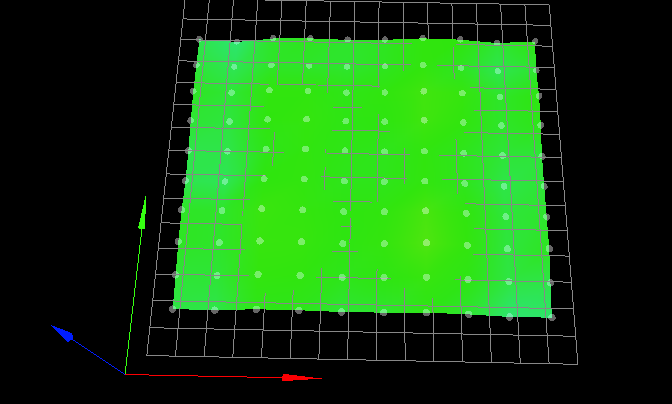

So, the saga continues. I managed to upgrade my bed to the new version, adjusted the frame and linear rails a bit and finally ended up with this mesh when probing the raw bed surface (no print surface attached yet)

So, as far as I am concerned, this is as flat as it's ever going to be.

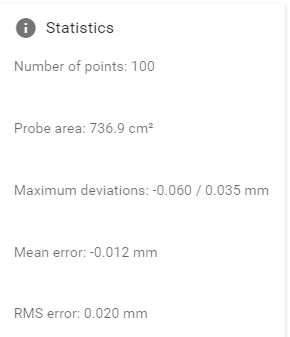

After installing the magnetic build surface I ended up with this as my final mesh:

So while a little less perfect, still good enough.

The fun thing now is that the behavior still exists... So it wasn't the bed afterall.

Here you can see a random brim from some print. As you can see the top right corner still has a massively different Z-Offset than the rest...

This was printed right in the center of the bed, so where the mesh is perfectly flat.Any further ideas....?

-

I am in the very same situation. Same kind of machine, but just one Z motor moving two ballscrews.

-

Can you try doing a higher density mesh of only the small area in the center of the bed where you will be printing and see if that helps. Or if you have the time, probe the entire bed with a higher density. You're using 100 points of a possible 441.

-

@phaedrux said in Bed mesh correction and tool offsets...:

Can you try doing a higher density mesh of only the small area in the center of the bed where you will be printing and see if that helps. Or if you have the time, probe the entire bed with a higher density. You're using 100 points of a possible 441.

I aleady do, and I have the very same problem

-

@egon-net You may want to start a new thread with your particular details so we can work through what's going on with your setup.

-

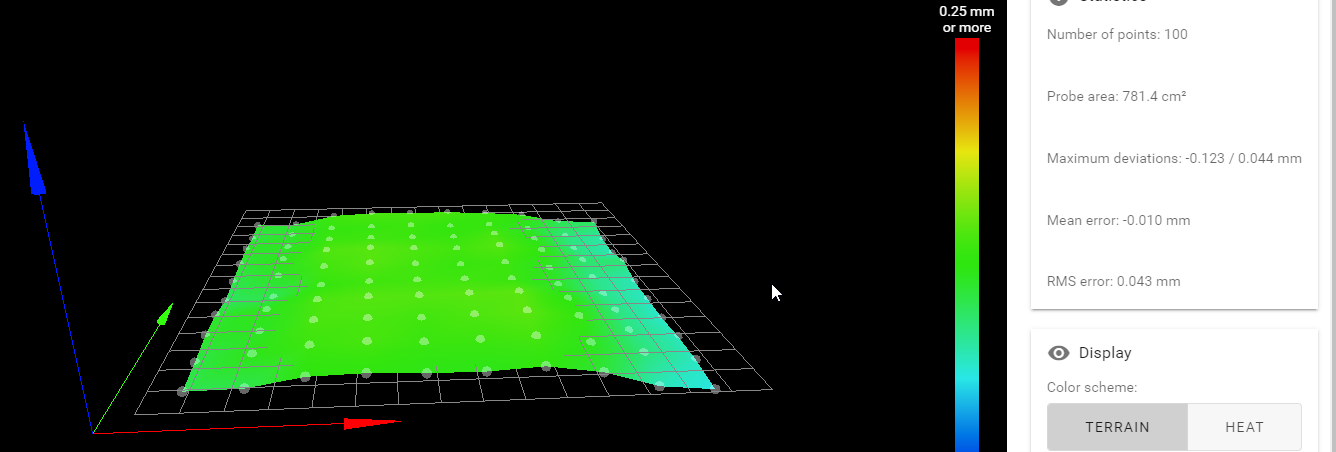

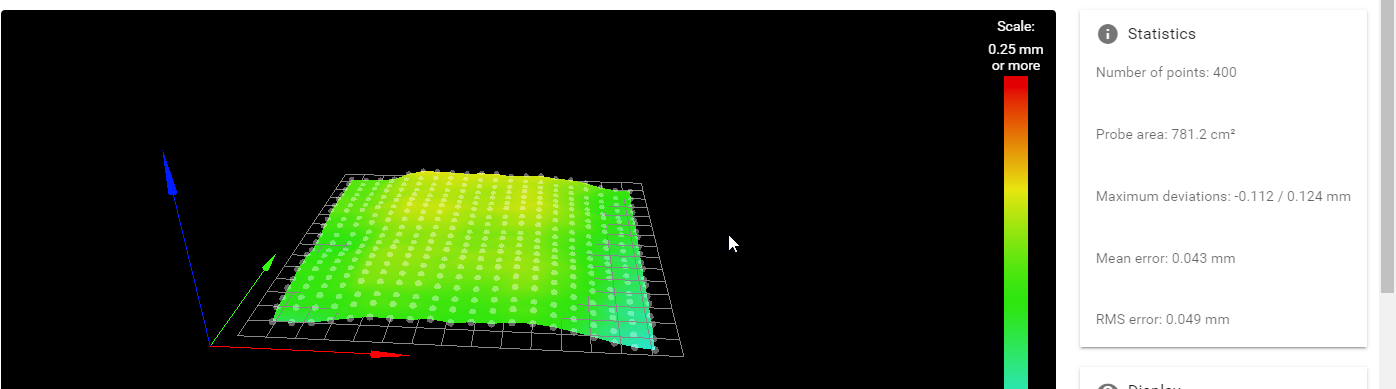

@phaedrux Here's one with 400 points:

What surprises me the most is that the magnitude of the error did not change at all, these "loose brims" look exactly the same as with the old bed, despite having a much flatter bed.

-

Can you do a test print with this file to get a sense of the entire bed surface?