Duet 3 Stepper drivers protection

-

Hello everyone,

just one short question:

- is there any possibility to destroy the Duet 3 6HC or its stepper drivers because of moving the axes manually in idle mode or when VIN is turned off?

I remember the LEDs of the stepper drivers of the Duet 2 turned on while moving an axis manually.

Thanks in advance and greetings from franconia,

Gabriel -

Yes there is always the risk of damaging the drivers when moving an axis manually. The stepper motor is also a generator when driven in reverse and the current has to go somewhere. It's usually safe to move them at a gentle pace by hand. Long rapid movements, not so much.

-

@gabriel

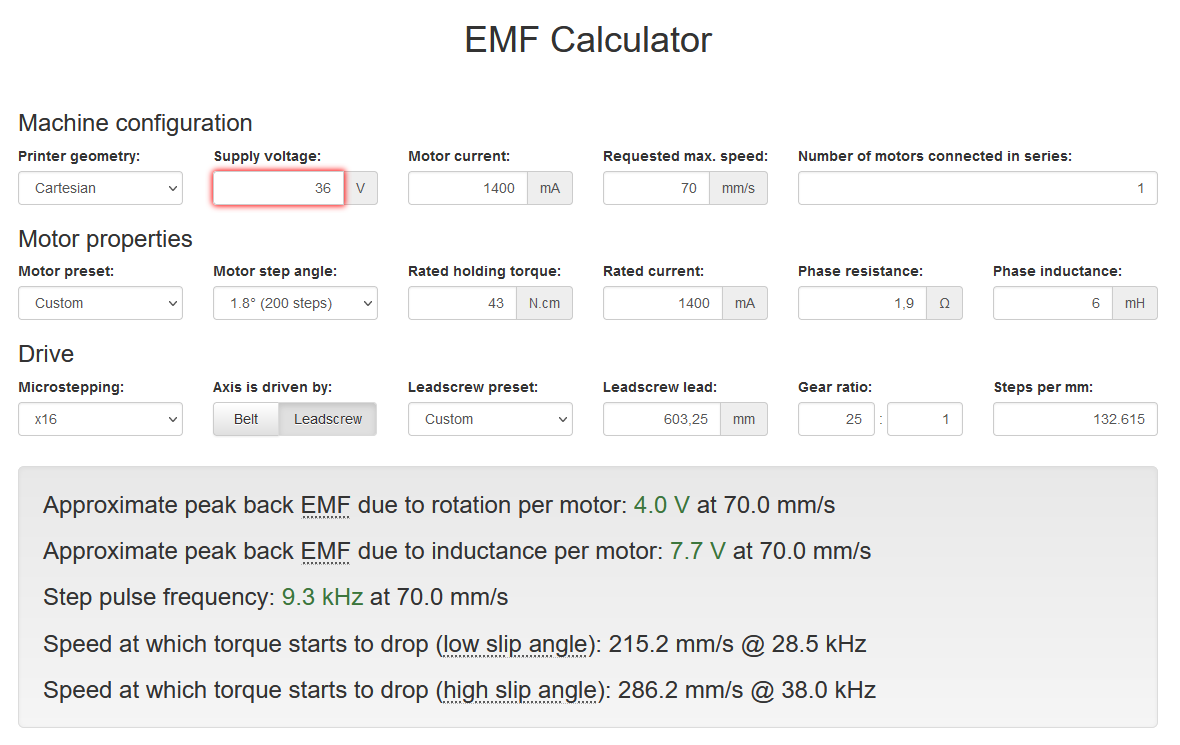

you can calculate the max speed you must not exceed with the EMF calculator

Just hack in the numbers of your stepper and play with the 'requested max. speed parameter' until the backEMF exceeds Vin.It'll tell you if you have to be extra careful or if the dead zone is far above the usual move_by_hand speed.

Also useful for printers with dropping beds or effectors at PowerOff. -

@o_lampe thanks for your reply. It's a chain drive that is moving some parts in circle.

The supply voltage of 36 V is no problem, as we modified the Duet so it can be used up to 48 V. The thing is, the chain drive can also manually be driven without the plug put into the wall outlet. And this is even wanted!

Greetings

Gabriel -

Couldn't a reverse current protection be implemented to prevent this? Maybe a diode or more robust electronics?

-

@chimaeragh said in Duet 3 Stepper drivers protection:

Couldn't a reverse current protection be implemented to prevent this? Maybe a diode or more robust electronics?

Duets already include protection against many issues which occur commonly, as based on our experience of supporting users and supplying warranty replacements over many years. There is always more protection that we could include, and Duet 3 boards include more protections than Duet 2 boards. However, there comes a point at which the cost/benefit ratio of adding additional protection isn't worth it.

In your particular example, protecting the electronics against rapid manual movement of stepper motors would require the following:

- All capacitors connected to VIN close to the stepper drivers to be rated at the maximum voltage that the driver itself can take (60V on Due 3 MB6HC, 40V ion Duet 3 Min, and 30V on Duet 2 WiFi/Ethernet). If the generated motor EMF exceeded 60V then the drivers would fail anyway.

- A diode that can handle the full rated current draw of all the stepper drivers simultaneously, or at least somewhat more than the fuse rating.. For the MB6HC this would be 20A or higher. Such a diode would not be cheap and would require a large PCB area for heatsinking.

Alternatively, a current sink could be added in the event that overvoltage is detected. Again, heatsinking would be a significant issue.

In summary, adding this type of protection to protect against an event that happens very rarely would lead to a significant increase in board cost and size, which in our opinion is not worthwhile. This doesn't mean that it wouldn't be worthwhile in a board designed for a particular machine configuration in which the risk of damage due to fast manual movement was higher than usual.

-