Dual z Stop and Piezo Bed Level

-

@ukwebb Could you please tell me how to get the exact values for the m671 command on my printer I have a bed of 330 330 and my leadscrews are left and right 25mm away from the bed I would then have M671 X-25:375 Y165:165 S20 and is the S20 for the test grid

-

@palgon no one can give you the exact measurements, other than you, as you have the printer to measure it!.

Home your printer, then move the print head Y position until it's in line with your Y rods. That will give you the Y value.eg something around 165

Then make sure x is at the 0 position and measure the distance from the tip of the nozzle to the approx centre of the z rod.

You'll get something like -30mm. Then move the X across as close as you can to the right side, and again measure the nozzle to rod distance. Remembering to add in the X position. So if the head is at position 330, and the rod is a further 30mm away, then your number is 360mm.So in the examples above the positions would be -30,165 and 360,165

-

@palgon said in Dual z Stop and Piezo Bed Level:

Do you have any tips or a checklist that I should now work through?

If you have uploaded the complete zip, DWC should be updated.

If you have access to DWC you can check versions under Setting/General and Machine SpecificAs several commands and files have changed under RRF3 generate a new config under

https://configtool.reprapfirmware.org -

@diy-o-sphere i have created a new rrf3 config i have saved my old one on my pc and on a usb stick so everything should be up to date then and thanks for your quick reply was just unsure since everything is new territory for me

-

-

@fcwilt I use two Z motors on my hevors which are connected on the board at slot Z1(Z2 is plugged with jumpers) and E1 and they both have their own limit switch

-

OK with two Z endstop sensors (or limit switches as you called them) ignore anything you read about homing Z with the Z probe.

You will be homing with the Z endstop sensors.

The Z probe will be used for:

- setting the Z=0 datum - which is needed for the next two items

- leveling the bed using the two Z steppers

- creating height maps for use with mesh compensation

Do you know how to configure for that?

Frederick

-

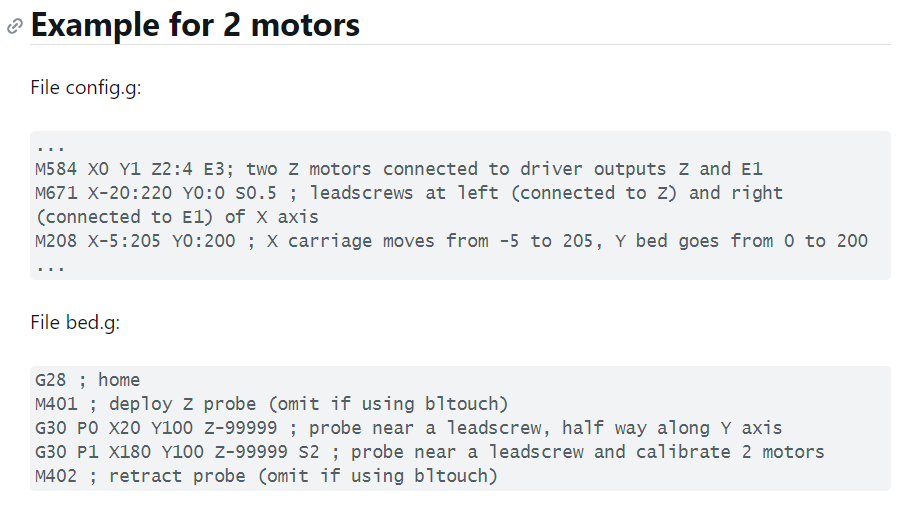

@fcwilt i'm trying to read up on this right now but i'm currently at this report https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors and looking at what i have to do in the bed.g in the config.g i currently only have M584 X0 Y1 Z2:4 E3 and

M671 X-25:165 Y355:165 S20 inserted further I am not yet

and i need to somehow integrate the endstop sensors (e1) well my goal is that it stops each axis individually and the piezo then applies the mash -

https://duet3d.dozuki.com/Wiki/Gcode#Section_M574_RepRapFirmware_Num_3

Find the example for two Z-motors -

how is that actually must one under rrf3 also everywhere where a z axis is defined a u axis add or searches the somewhere out for example with m350 /m92 /m201or m208 and can it be that I have the M584 command wrong because in my old M584 XO Y1 Z2:3 U3 E4 is written

-

@palgon

Extruder is swaped with 2. motor of ZEdit:

M584 X0 Y1 Z2:4 E3

should be

M584 X0 Y1 Z2:3 E4 -

@diy-o-sphere have a clean cfg on the printer where nothing is difiniert. this I have now copied times and test times edited and this is now the result

config.gcan the following command actually be inserted under M584 or where must it be inserted M574 Z1 S1 P "io2.in+io3.in" ; Z axis with two motors, individual min endstops, active high

-

@palgon said in Dual z Stop and Piezo Bed Level:

how is that actually must one under rrf3 also everywhere where a z axis is defined a u axis add or searches the somewhere out for example with m350 /m92 /m201or m208 and can it be that I have the M584 command wrong because in my old M584 XO Y1 Z2:3 U3 E4 is written

Under older versions of the firmware you had to breakout one of the Z steppers as another letter.

Now you don't have to do that because the M574 command for the Z axis allows specifying two endstop sensors.

My printer controlled by a Duet 2 WiFI/Diuex 5 combo has three Z steppers and this is what the M574 command looks like for the Z axis:

M574 Z1 S1 P"!duex.e2stop + !duex.e3stop + !duex.e4stop" ; configure active-high endstop for low end on ZFrederick

-

@palgon said in Dual z Stop and Piezo Bed Level:

config.g

Below should be the correct code for limits and endstops but there are to much other issues

like

M671 missing

Wrong declaration of Z-Probe

So I also expect issus with the generated files for homing beg.g ...etc.

To much to fix by hand....Got through the configurator step by step

; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X295 Y295 Z390 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S1 P"zstop+e0stop" ; configure active-high endstop for low end on Z via pin zstop+e0stop -

@diy-o-sphere I'm just a newbie when it comes to writing cfg and am today (25 Jul 2021, 17:49) just started with rrf3 and to the z prob entries I have not yet come because it's all very new to me I need longer for. because I have to read everything but thanks for the right end stops and because the printer under 2.05.1 is also only run without sample I wanted to work out the first time again and then teach him how he has to move with the sensor

-

If you want to do it step by step, that's fine, I just wondered.

I have also done the conversion to RRF3 by hand and really learned a lot.

But I would still recommend to do as much as possible with the tool, even if you only take it as a reverence to compare... -

@diy-o-sphere I'm just about to create another one with the tool this time even with piezo settings am curious how the same looks

-

@DIY-O-Sphere the newly created cfg looks totally different hope that this looks better and that I'm not on the wrong track. and yes I have to insert m671 and then also that in the bed.g . furthermore I have to look at what the manufacturer makes for information on M558

the whole thing I will do tomorrow

-

While the configurator tool and many folks put the M671 command in config.g I put it it bed.g because it is related to the operation of bed.g and nothing else.

It also means if I need to change M671 I edit bed.g and the next time I do G32 the new M671 settings take effect - no need to re-boot the printer to cause config.g to be processed again.

It is just my personal preference and it doesn't change the behavior of bed leveling.

Also remember to set the Z=0 datum (with a single G30) after leveling the bed.

Frederick