insufficient axis homed when start printing

-

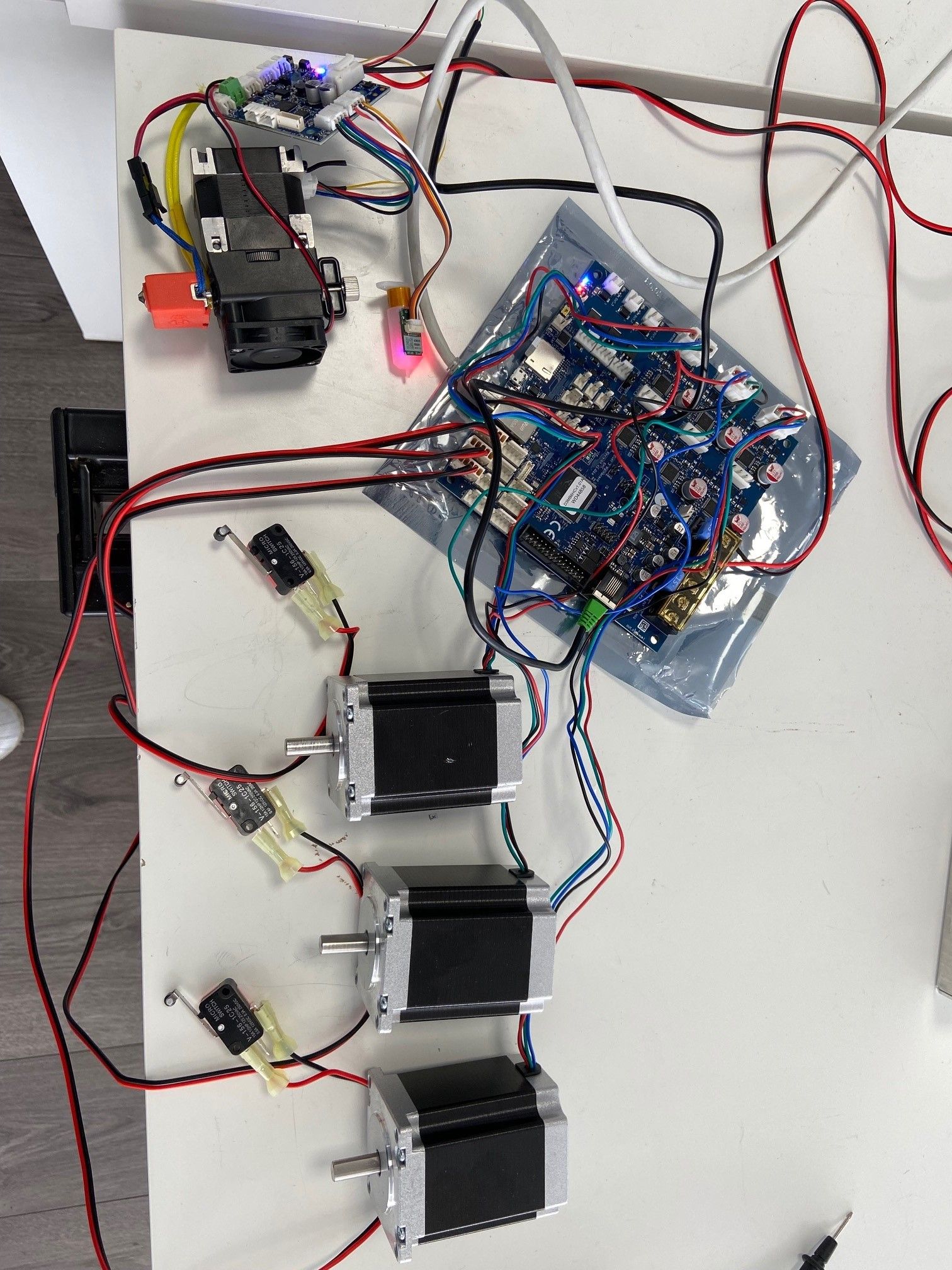

Hi guys, I'm a new user of the duet platform. Today I wired everything up. My configuration: standalone duet 3 6HC, 1x tool board directly wired to mainboard, hemera&volcano printhead and corexy setup. Managed to connect everything, connect to LAN, startup DWC, update firmware and setup the basics using the config tool. I can move and home the axis, play with the fan, extruder and heater. Also use cura with plugin to make a gcode file and load that to DWC and start the print. Since the printer is not build yet I have the electronics laid out on the table.

Unfortunately, when start printing within seconds the error "insufficient axis homed" pops up and when checking, indeed the previous homed axis arent anymore.

Help is welcome! (Config under the picture)

; Configuration file for Duet 3 (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.2 on Mon Aug 30 2021 18:34:21 GMT+0200 (Central European Summer Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Sculptura" ; set printer name

M669 K1 ; select CoreXY mode; Wait a moment for the CAN expansion boards to start

G4 S2; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P121.0 S1 ; physical drive 121.0 goes forwards

M584 X0.0 Y0.1 Z0.2 E121.0 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X100 Y100 Z100 S0 ; set axis maxima; Endstops

M574 X1 S1 P"io0.in" ; configure active-high endstop for low end on X via pin io0.in

M574 Y1 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin io1.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"^121.io0.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z3.3 ; set Z probe trigger value, offset and trigger height

M557 X15:85 Y15:85 S20 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0

M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"121.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"121.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P0 S"Volcano " D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

T0 ; select first tool -

First let me ask you to copy-and-paste configuration files and such using the </> tag.

When you use that tag correctly you will get something like this - which is your config.g file:

; Configuration file for Duet 3 (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.2 on Mon Aug 30 2021 18:34:21 GMT+0200 (Central European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Sculptura" ; set printer name M669 K1 ; select CoreXY mode ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P121.0 S1 ; physical drive 121.0 goes forwards M584 X0.0 Y0.1 Z0.2 E121.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X100 Y100 Z100 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io0.in" ; configure active-high endstop for low end on X via pin io0.in M574 Y1 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^121.io0.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z3.3 ; set Z probe trigger value, offset and trigger height M557 X15:85 Y15:85 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"121.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"121.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 S"Volcano " D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous T0 ; select first tool -

-

@agileproductontwikkeling The most common cause of the homing status changing to "not homed" after they have been successfully homed, is that the motors lose power. Check the start code of the file you are trying to print for any commands which might do that such as M84.

-

ah ok good point, will do in the future. Below homing file, and snippet of the gcode file.

I found G28 "homing" in the gcode file, deleted that in the and now it prints. Checked cura, and saw cura placed this in the "start G-code".

Since I home on power up using G28 in the config file, I deleted this in the cura "start G-code" and all is well. Thanks for pointing me in the right direction!

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.2 on Mon Aug 30 2021 18:34:21 GMT+0200 (Central European Summer Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-105 Y-105 F1800 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-105 ; home X axis G1 H1 Y-105 ; home Y axis G1 X5 Y5 F6000 ; go back a few mm G1 H1 X-105 F1800 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-105 ; then move slowly to Y axis endstop G90 ; absolute positioning G1 X15 Y15 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning;FLAVOR:RepRap ;TIME:1291 ;Filament used: 1.43758m ;Layer height: 0.1 ;MINX:32.4 ;MINY:32.4 ;MINZ:0.3 ;MAXX:67.6 ;MAXY:67.6 ;MAXZ:20 ;Generated with Cura_SteamEngine 4.10.0 T0 M104 S200 M109 S200 M82 ;absolute extrusion mode ;G28 ;Home G1 Z15.0 F6000 ;Move the platform down 15mm ;Prime the extruder G92 E0 G1 F200 E3 G92 E0 M83 ;relative extrusion mode G1 F1500 E-6.5 ;LAYER_COUNT:198 ;LAYER:0 M107 G0 F3600 X34.82 Y34.439 Z0.3 ;TYPE:SKIRT G1 F1500 E6.5 G1 F1800 X35.417 Y33.937 E0.07783 G1 X36.062 Y33.5 E0.07774 G1 X36.748 Y33.131 E0.07772 G1 X37.469 Y32.834 E0.07781 G1 X38.217 Y32.612 E0.07785 G1 X38.983 Y32.468 E0.07777 G1 X40 Y32.4 E0.1017 G1 X60 Y32.4 E1.99561 G1 X60.778 Y32.44 E0.07773 -

Doing any movement commands in config.g is generally considered a bad idea. A unexpected power glitch can result in movement for which the printer is not prepared for some reason, such as you haven't removed the previous print.

Doing it in your print start code is a much better place.

Frederick

-

@agileproductontwikkeling another place you can do homing is in the start.g file. You could make homing conditional on the axes not having been homed already.

-

ah ok... I'm not trying to reinvent the wheel. Its fine if the printer homes when the print starts, however I currently see 2 problems in that case:

First: The printer only homes after the heaters have reached their setpoint. Not a real big issue but I hate unnecessary waiting

I will have a 1000mm z-axis so homing takes a while. I guess this can be circumvented but it seems the default situation and I'm not yet comfortable enough with the whole system to alter sequences.

I will have a 1000mm z-axis so homing takes a while. I guess this can be circumvented but it seems the default situation and I'm not yet comfortable enough with the whole system to alter sequences.Second: When the printer is already homed, for instance when starting up a second print, it will halt the print and causes the " insufficient axis homed". Of course I could restart the print and it will work but not elegant.

I could do homing in the start.g file, but how can I make it conditional? I found this but seems not conclusive. https://forum.duet3d.com/topic/17083/conditional-homing-and-z-height-fine-adjustment/20

-

@agileproductontwikkeling Lots of questions but I'll do my best to answer them. Firstly uderstand that homing files are nothing more than macros, and macros are nothing more than a sequence of commands which get executed consecutively. Some macros are "system" macros. These include the homing files so they generally reside in the system folder. Other macros are what I call "user macros" and they usually go on the "macros" folder. Macros can be called from pretty much anywhere or they can be run "stand alone" and they can also call other macros.

Regarding your first question, you can start heating the hot end (and bed if you want to) by adding the commands to the start of your homing macro. So for example, you could use G10 T0 S195 which will set the active temperature for tool zero to 195 but it will not wait. So you can then carry on with the rest of your homing while the tool is heating. At some point, you will want to wait for the active temperature(s) to be reached so you could use M116 at the end of your homing file or elsewhere. The potential problem with that is that homing will always heat the hot end to 195 and you might not always want to do that. So a better approach might be to use another macro such as start.g or some other "pre-print" macro that you define. That macro would have the G10 T0 S195 command at the start, then M98 P"homeall.g" then the M116. That would start the tool heating, then run the home all macro, then wait for the temperatures to reach their set points. But you could run homeall stand alone or in some other place, and it will not heat the hot end.

Ref your second and last questions, I'm not sure why you are getting "insufficient axes homed messages" when homing a second time. Do you see those messages when homing for the first time? This has nothing to do with conditional gcode (although you could suppress the message by not homing axes which have already been homed). I suspect you might have something amiss with your BlTouch settings/G31 but I don't use one so can't advise - maybe someone else will.

-

I had a similar problem when I set up my Jubilee printer. It turns out that Cura inserts some commands before the Cura start code. This included selecting a tool and homing the printer. The jubilee can not be homed with a tool selected. The answer turned out to be to first remove all homing instructions from the Cura start code file and to insert homing in the Duet start.g file which is executed before Cura can send any instructions. That way, the printer is homed when Cura calls for it's first homing.

My issue was specifically Jubilee related and this may not be anything related to your issue. -

@jens55 said in insufficient axis homed when start printing:

I had a similar problem when I set up my Jubilee printer. It turns out that Cura inserts some commands before the Cura start code. This included selecting a tool and homing the printer.

Hmm...

I have Cura 4.10.0 and this is what it inserts in the print start code:

; Cura (Repeteir flavor - no temps) ;M109 S0 ; set extruder temp and wait (no wait with S0) ;M82 ; absolute E moves ;M98 P"print_begin.g" ; invokes my print start code ;G92 E0 ; set E position ;G92 E0 ; set E position again (have no idea why) ;G1 F1800 E-1 ; do initial retractI wonder why you are seeing something different.

Frederick

-

@agileproductontwikkeling said in insufficient axis homed when start printing:

First: The printer only homes after the heaters have reached their setpoint. Not a real big issue but I hate unnecessary waiting

I will have a 1000mm z-axis so homing takes a while. I guess this can be circumvented but it seems the default situation and I'm not yet comfortable enough with the whole system to alter sequences.

I will have a 1000mm z-axis so homing takes a while. I guess this can be circumvented but it seems the default situation and I'm not yet comfortable enough with the whole system to alter sequences.That is easily dealt with, usually. There are commands that start the heating process and continue and commands that start the heating process and waits for temp to be reached.

For example M104 sets the extruder heating and continues on, M109 sets the extruder heating and waits.

The is M116 which waits for all temps to reach the set point.

So the basic steps are

M104 Snnn ; set extruder temp and start heating M140 Snnn ; set bed temp and start heating G28 ; home printer M116 ; wait for extruder and bed to reach tempSecond: When the printer is already homed, for instance when starting up a second print, it will halt the print and causes the " insufficient axis homed". Of course I could restart the print and it will work but not elegant.

Something is wrong with your code if that is happening. We need to look at your various configuration files and the start of a typical print file.

Frederick

-

So I need to figure out what homing/tool/temp settings/commands are executed where: config, start, homing, cura. For me its not completely clear yet what makes the most sense.

Anyway the main problem I had is gone: I now have a more or less working pile of parts on my desk. I'm going to build the actual printer first and work from there.

thanks so far!

-

@agileproductontwikkeling said in insufficient axis homed when start printing:

Anyway the main problem I had is gone:

So what made the problem go away?

Frederick

-

@fcwilt Dont give the homing command when already homed. Not sure why that is a problem, but apparently it is in my case.

-

@agileproductontwikkeling said in insufficient axis homed when start printing:

@fcwilt Dont give the homing command when already homed. Not sure why that is a problem, but apparently it is in my case.

Homing when already homed should never be an issue as (one of) the first thing a G28 command does is mark the axis as un-homed.

You have something wrong in your code.

We just need to find the problem and correct it.

Frederick

-

@fcwilt said in insufficient axis homed when start printing:

Homing when already homed should never be an issue as (one of) the first thing a G28 command does is mark the axis as un-homed.

You have something wrong in your code.

It most certainly CAN be a problem .... see my various postings on the Jubilee printer.

A Jubilee printer can only be homed when it has no tools loaded in the tool changer. The first thing Cura does, and this is BEFORE any Cura start code is executed, is to select a tool. Generally the homing is done after that in the Cura start code.

There is no known way of bypassing the fact that Cura selects a tool even before executing it's start codes. -

@jens55 said in insufficient axis homed when start printing:

It most certainly CAN be a problem .... see my various postings on the Jubilee printer.

You write the code that does the homing - you can code it as needed.

There is no known way of bypassing the fact that Cura selects a tool even before executing it's start codes.

How is that possible - since the code in the sliced file is doing all the work.

The first command I see Cura 4.10.0 generate is M109 S0.

When RRF processes that command it selects the tool.

The next command I see is M82 which has no effect on tools.

The third command I see is the call to my own start code where I can, if needed, de-select the tool selected by the M109.

So perhaps I am missing the problem but I just don't see it.

Frederick

-

I made one change to Cura 4.10.0 to use RepRap as the "gcode flavor" instead of Repetier.

I still am setting all temps in Cura to 0 as I don't let slicers control temps.

The only difference I see in the generated code, compared to Repetier, is a T0 as the very first command.

But the result is the same in that when my code gets executed I still can de-select the tool.

Frederick

-

@fcwilt said in insufficient axis homed when start printing:

So perhaps I am missing the problem but I just don't see it.

It is a bit of an esoteric issue and yes, you are missing something.

I should first mention that I use the latest Master Branch of Cura rather than plain old Cura.

What happens, even before the start code from Cura is run, is that Cura calls for a tool and then sets up temperatures for said tool and the bed. The temperature calls can be bypassed but no matter what you do, Cura calls for a tool.

Generally the Cura start code calls for homing.

The Jubilee printer can not home if a tool is mounted period. If you try to do that you get all kinds of errors. Yes, you can most certainly remove all the code that generates the errors but you can't bypass the crash that happens as a result of trying to home while a tool is physically mounted in the tool changer.I think we are getting way too fixated on a specific setup that the OP might not even have. There are apparently a few other printers that throw errors when you try to do a home with a tool mounted but this might still not be the issue with the OP. I only mentioned this issue because I had a bit of a struggle finding why things were happening and I wanted to make some mention in this thread about the issues I encountered in case somebody searches for the same problem.

I am more than happy to discuss more details via email to clarify things for you.