print finished before end of start.g

-

@fcwilt

yes i wanted to disable compensation just to eliminate any possible issues with the g28 in the start.gonly thing in the slicer start code is an m117 "print damnit"

(i even had tried a T0 just to see if i could get Tpre0 or Tpost0 to display (m117 in each to indicate activity)old files from 2.03 had heater/bed temp settings etc.

nothing changes.

from my understanding start.g runs completely before the machine starts chewing on the selected print file.

in which case id see the final m117 in the start.g before i got the print finished notification.

as it is now it appears that right after the g28 activity it "finishes" then 5 seconds later my m117 "start.g finished" shows up.

I've been reading more on the v3.4 but i don't see anything in there for correcting an issue like this but i can install it today and see if anything changes.

regards, james

-

@jawsn3d From what I can gather, the print finished issue occurs when running start.g and after the end of G28 within that file yes? If so, then G28 calls the macro "homeall" so that would be the place to look for the cause. Can you post your homeall.g here so that one of us can take a gander at it.

As for your other issues, nothing leaps out at me from your config.g (but I might have missed something). It might be an idea if you rename that file as something like configOld.g so that you keep a record of things, then create a new config.g from that file but with all the old commented out commands removed. It'll make life easier for you and us.

One thing to check is that you have a M501 command near the end of your config.g file. The comment you have after that is "load config.g on start up". That comment is incorrect because the it's config-override.g file which gets run. So essentially, config g reads each line sequentially. When it encounters M501 it will load each line from config-override.g. As the name suggests, any commands that are in this file will override any commands that have just been read from config.g. So maybe there is something in config-override.g which is causing things like your second bed heater to appear. Personaly, I hate the concept of having the override file and never use it. The reason is that sooner or later it will bite you because you'll want to change something in config.g and find that the changes have no effect (because they are being overridden by what is in the override file).

-

m501 is present right before some misc commands and an m300 diddy.

carp....your right i should have checked homeall and added some m117 comments

homeall.g

cleaned it up and added m117 comments for a test after i make breakfast; homeall.g ; called to home all axes ; ; generated by james williams for rrf 3.1.1 4-17-2021 M280 P0 S160 I1 ; Re-Set the probe M117 "PROBE RESET" ; X AXIS HOME G91 ; relative positioning M913 X50 Y50 ;SET X Y TO 50% CURRENT G1 H2 Z5 F5 ; lift Z relative to current position ;G1 H2 X10 F2200 ; go back a few mm on X G1 H1 X-810 F2200 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F1000 ; go back a few mm G1 H1 X-100 F200 ; move slowly to X axis endstop once more (second pass) ;G1 H2 Z-1 F10 ; lower Z again ;G90 ; absolute positioning ;Y AXIS HOME ;G91 ; relative positioning ;G1 H2 Z1 F10 ; lift Z relative to current position G1 H1 Y-215 F2200 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 Y5 F600 ; go back a few mm G1 H1 Y-215 F200 ; move slowly to Y axis endstop once more (second pass) ;G1 H2 Z-5 F5 ; lower Z again NOT USED WITH G30 FOR Z HOME M913 X100 Y100 ; SET X Y TO 100% CURRENT M117 "MOTOR FORCE CURRENT AT 100%" G90 ; absolute positioning G1 X300 Y175 F6000 ; go to first probe point M400 M117 "FIRST PROBE POINT" G30 ; home Z by probing the bed ;G29 S1 ; disable and put in start.g load stored bed height map ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 S2 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning ;M280 P3 S90 I1 ; retract mechanical Z probeconfig overide is heater models and workplace coordinates, genreated and not edited except with m500 after a recent PID on the hotend.

; config-override.g file generated in response to M500 at 2021-08-22 16:14 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 R0.129 C700.000:700.000 D10.00 S1.00 V0.0 B1 I0 M307 H1 R1. C241.283:241.283 D5.01 S1.00 V24.1 B0 I0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 -

cleaned up the bed/config.g to remove my brain droppings

config.g; NEW JAWS6 build Configuration file for Duet WiFi/Ethernet (firmware version 3.1.1) ; executed by the firmware on start-up ; generated by RepRapFirmware Configuration Tool v3.1.9 on Sat Nov 28 2020 17:26:32 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves G21 ; Work in millimetres M575 P1 B57600 S1 ;set paneldue i7 baud to 57,600 M550 P"JAWS N 3D" ; set printer name ; Network M552 S1 P192.168.4.2 ; enable network M553 255.255.255.0 ;set mask M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 X-axis goes backwards M569 P1 S1 ; physical drive 1 Y-axis goes forwards M569 P2 S1 ; physical drive 2 Z-axis goes forwards Z1 M569 P3 S0 ; physical drive 3 HERMES/HEMERA goes reverse M569 P4 S1 ; physical drive 4 goes forwards M569 P5 S1 ; physical drive 5 goes forwards M569 P6 R-1 ; physical drive 6 disabled M569 P7 S1 ; physical drive 7 goes forwards Z2 M569 P8 S1 ; physical drive 8 goes forwards Z3 M569 P9 S1 ; physical drive 9 goes forwards Z4 M584 X0:5 Y1 Z2:7:8:9 E3:4 ; set drive mapping M350 X16 Y16 Z1 E16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z1000.00 E409.00:420.00 ; set steps per mm M566 X4000.00 Y1000.00 Z3.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y8000.00 Z30.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y800.00 Z0.1 E250.00:250.00 ; set accelerations (mm/s^2) M906 X1400 Y800 Z800 E800:800 I10 ; set motor currents (mA) and motor idle factor in per cent M84 S0.01 ; Set idle timeout ; TESTING MULTI Z STEPPERS M671 X-117.0:-117.0:829.15:829.15 Y7.7:337.9:7.7:337.9 S0.5 ; leadscrews at RIGHT REAR Z1, RIGHT FRONT Z2, LEFT REAR Z3, LEFT FRONT Z4 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X700 Y320 Z685 S0 ; set axis maxima test volume ;M208 X790 Y340 Z685 S0 ; 7 2021 WARNING ROUGH measured print volume USE WITH CAUTION ESPESIALLY WITH PART FAN INSTALLED ; ENdstops v3.1.1 code M574 X1 S1 P"!^xstop" ; configure active-low endstop for low end on X via pin xstop M574 Y1 S1 P"!^ystop" ; configure active-low endstop for low end on Y via pin ystop M574 Z1 S2 ; The BLtouch Z probe acts as a Z axis end-stop & is located at Z axis's minimum M950 J1 C"e1stop" ;Configure EMERGENCY STOP E1 endstop M581 P1 T0 R0 ;EXT TRIGGER PIN1, TRIGGER ANYTIME ; Z-Probe v3.1.1 NEW cofig M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H3 F30 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X1.0 Y-28.5 Z3.3 ; set Z probe trigger value, offset and trigger height M557 X15:700 Y15:300 S100 ; define mesh grid ; Heaters v3.1.1 NEW CODE ;BED HEATERS 2x 400X400 110V MAINS PADS, CONTROLLED IN PARALLEL BY 2x SSR, 110V MAINS KILL VIA "PS_ON" CONTROL OF 110V CONTACTOR-SOON M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 A"BED TEMP" ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 Q5 ; create bed heater output on bedheat and map it to sensor 0 aka bedtemp Q is pwm 5hz M307 H0 B1 S1.0 ; disable bang-bang mode for the bed heater and set PWM limit M140 P0 H0 S62 R0 ; map heated bed to heater 0, active to 62c standby to 0c M143 P0 H0 S280 ; set temperature limit for heater 0 to 120C M144 P0 S0 ;TOOL 0 HEATER M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 A"E0 TEMP" ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.0 ; disable bang-bang mode for heater and set PWM limit M140 P1 H1 S200 R0 ; map extruder 0 to heater 1, active to 222c standby to 0c M143 H1 S280 ; set temperature limit for heater 1 to 280C ;M308 S2 P"e1temp" Y"thermister" T100000 B4138 A"SENTINEL TEMP" ;EXPERIMENT FOR TEMP SENSOR FOR CHAMBER/ETC ; FANS ;Parts cooler fan0 M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off ;Hemera Fan1 M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools v3.1.1 NEW CONFIG ;TOOL 0 M563 P0 S"Volcano E0" D0 H1 F0 ; define tool 0 with heater 1 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M302 P0 S180 R180 ; set min extrude /retract T's ;TOOL 1 NOT YET ;M563 P0 S"Volcano E1" D1 H2 F0 ; define tool 0 ;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets ;G10 P0 R0 S215 ;G29 S1 ; disable and put in start.g load stored bed height map M376 H10 ; Bed compensation tapered up to 10mm M501 ;load config.g on startup ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M911 S18 R20 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss G4 S10 M400 G4 S5 M400 M98 P/macros/MARIO ;G4 S1 ;M98 P/macros/IMPERIALbed

; bed.g v3.1.1 ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.1.9 on Sat Nov 28 2020 17:26:32 GMT-0600 (Central Standard Time) M564 S1 H1 ;H1 = forbid movement of axes that have not been homed, H0 = allow movement of axes that have not been homed S1 = limit movement within axis boundaries, S0 = allow movement outside boundaries M561 ; clear any bed transform M671 X-117.0:-117.0:829.15:829.15 Y7.7:337.9:7.7:337.9 S0.5 ;Z leadscrews at RIGHT REAR Z1, RIGHT FRONT Z2, LEFT REAR Z3, LEFT FRONT Z4 ; Z SCREW LOCATION FROM ORIGIN CAN BE NEGATIVE NUMBERS OUTSIDE PRINT AREA ; MULTIPLE Z STEPPER TESTING ;G28 ; home NOT NECESSARY ;M401 ; deploy Z probe (omit if using bltouch) G30 P0 X0 Y0 Z-99999 ; probe near a leadscrew G30 P1 X0 Y330 Z-99999 ; probe near a leadscrew G30 P2 X712.15 Y0 Z-99999 ; probe near a leadscrew G30 P3 X712.15 Y330 Z-99999 S-1 ; probe near a leadscrew and calibrate NOW 4 motors S-1 COMPENSATION CALCULATED BUT NOT ENABLED G1 X300 Y175 F3000 ;MOVE TO PROBE POINT G30 ; probe the bed and enable compensation....IF S-1 IS CHANGED ABOVE ;M402 ; retract probe (omit if using bltouch) -

Hi again,

We still need to see the start of the file you are actually trying to print.

That's a likely source of the problem.

Frederick

-

i retested with the cleaned .g files.

it displays probe reset, and motor current to 100% before it probes z and gives me the first probe point notification.

print file finished pops up before i get the g28 complete notification from the homeall file as well as the start.g finished notifications

current homeall since i cant seem to edit my previous post

; homeall.g ; called to home all axes ; ; generated by james williams for rrf 3.1.1 4-17-2021 M280 P0 S160 I1 ; Re-Set the probe M117 "PROBE RESET" ; X AXIS HOME G91 ; relative positioning M913 X50 Y50 ;SET X Y TO 50% CURRENT G1 H2 Z5 F5 ; lift Z relative to current position ;G1 H2 X10 F2200 ; go back a few mm on X G1 H1 X-810 F2200 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F1000 ; go back a few mm G1 H1 X-100 F200 ; move slowly to X axis endstop once more (second pass) ;G1 H2 Z-1 F10 ; lower Z again ;G90 ; absolute positioning ;Y AXIS HOME ;G91 ; relative positioning ;G1 H2 Z1 F10 ; lift Z relative to current position G1 H1 Y-215 F2200 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 Y5 F600 ; go back a few mm G1 H1 Y-215 F200 ; move slowly to Y axis endstop once more (second pass) ;G1 H2 Z-5 F5 ; lower Z again NOT USED WITH G30 FOR Z HOME M913 X100 Y100 ; SET X Y TO 100% CURRENT M117 "MOTOR FORCE CURRENT AT 100%" G90 ; absolute positioning G1 X300 Y175 F6000 ; go to first probe point M400 M117 "FIRST PROBE POINT" G30 ; home Z by probing the bed ;G29 S1 ; disable and put in start.g load stored bed height map ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 S2 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning ;M280 P3 S90 I1 ; retract mechanical Z probe -

sorry about that, print file start is as follows

it never gets to displaying the m117 "al is great" so the issue is likely above that point?

;FLAVOR:RepRap ;TIME:1255 ;Filament used: 1.33271m ;Layer height: 0.1 ;MINX:290.4 ;MINY:140.4 ;MINZ:0.3 ;MAXX:309.6 ;MAXY:159.6 ;MAXZ:20 ;Generated with Cura_SteamEngine 4.5.0 T0 M190 S65 M104 S220 M109 S220 M82 ;absolute extrusion mode M117 "Al is greeeeaaat PRINT FILE START CODE" M83 ;relative extrusion mode G1 F1500 E-6.5 ;LAYER_COUNT:198 ;LAYER:0 M107 ;MESH:test cube.stl G0 F3600 X290.4 Y159.6 Z0.3 ;TYPE:WALL-OUTER G1 F1500 E6.5 G1 F1800 X290.4 Y140.4 E1.91578 G1 X309.6 Y140.4 E1.91578 G1 X309.6 Y159.6 E1.91578 G1 X290.4 Y159.6 E1.91578 G0 F3600 X290.4 Y159.2 G0 X291.19 Y158.81 ;TYPE:SKIN G1 F1800 X291.19 Y141.19 E1.75813 -

Thanks.

Nothing unusual there.

And you are not getting any error messages in the DWC console?

Frederick

-

on full reboot i get a heater temp error as it seems to energize the hotend momentarily during bootup.

during a reload/reset that message never appears.

im thinking its time to look at the v3.4 tree and see which of the beta's is solid. i may have a corrupted 3.3?

-

@jawsn3d

for posteritym115 FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.3 ELECTRONICS: Duet Ethernet 1.02 or later + DueX5 FIRMWARE_DATE: 2021-06-15 21:45:03m122

=== Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3 (2021-06-15 21:44:54) running on Duet Ethernet 1.02 or later + DueX5 Board ID: 08DGM-917NK-F2MS4-7J1F4-3SJ6Q-1YUJG Used output buffers: 3 of 24 (24 max) === RTOS === Static ram: 23876 Dynamic ram: 71752 of which 320 recycled Never used RAM 15612, free system stack 130 words Tasks: NETWORK(ready,24.5%,233) HEAT(delaying,0.0%,314) Move(notifyWait,0.1%,313) DUEX(notifyWait,0.0%,24) MAIN(running,75.4%,445) IDLE(ready,0.0%,29), total 100.0% Owned mutexes: === Platform === Last reset 00:23:23 ago, cause: power up Last software reset at 2021-09-04 08:06, reason: User, GCodes spinning, available RAM 19236, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 0 MCU temperature: min 18.7, current 30.9, max 31.5 Supply voltage: min 23.9, current 24.1, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/8/8, gc cycles 0 Driver 0: position 24000, standstill, SG min/max 24/487 Driver 1: position 14000, standstill, SG min/max 0/287 Driver 2: position 6300, standstill, SG min/max 0/950 Driver 3: position 0, standstill, SG min/max not available Driver 4: position 0, standstill, SG min/max not available Driver 5: position 0, standstill, SG min/max 4/464 Driver 6: position 0, temperature-warning, standstill, SG min/max not available Driver 7: position 0, standstill, SG min/max 0/881 Driver 8: position 0, standstill, SG min/max 0/943 Driver 9: position 0, standstill, SG min/max 0/867 Driver 10: position 0 Driver 11: position 0 Date/time: 2021-09-04 09:36:31 Cache data hit count 4294967295 Slowest loop: 19.73ms; fastest: 0.14ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 3.8ms, write time 0.0ms, max retries 0 === Move === DMs created 83, maxWait 177260ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 10, completed moves 10, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === DueX === Read count 1, 0.04 reads/min === Network === Slowest loop: 16.96ms; fastest: 0.02ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 Interface state active, link 100Mbps full duplex -

@jawsn3d said in print finished before end of start.g:

on full reboot i get a heater temp error as it seems to energize the hotend momentarily during bootup.

during a reload/reset that message never appears.

im thinking its time to look at the v3.4 tree and see which of the beta's is solid. i may have a corrupted 3.3?

I am currently only using 3.3. I'm not sure how it would be possible to corrupt it.

Possibly a flaky SD card? Other folks have cured unusual problems with a new card. Easy enough to try - if you've got another card.

I don't get any heater errors on reboot like you are seeing. That worries me a bit. I will take a closer look at your config.g file

Frederick

-

-

@fcwilt

We're going to go grab a new SD card now. as I've had some Oddities I can't explain. Such as bouncing off the x axis and stop repeatedly. As well as the heater reading 2000 degrees Centigrade during a hard reboot.I edited out the m84 and now suddenly it's bouncing off of the Y end stop and making lovely noises.

I will retest with a new SD card within the next 2 hours hopefully and be able to report back.

I appreciate the help and third pair of eyes on our problem if you're ever in the west suburbs of Chicagoland give me a holler I owe you as some beers.

-

@jawsn3d said in print finished before end of start.g:

I edited out the m84 and now suddenly it's bouncing off of the Y end stop and making lovely noises.

Actually that's good.

It suggests to me the aborted printing was caused by the M84.

And removing it has revealed problems with your Y endstop wiring and/or configuration.

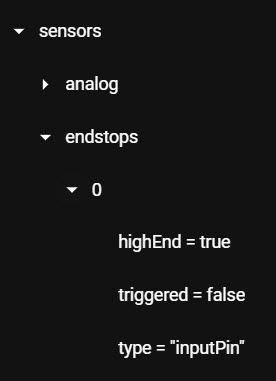

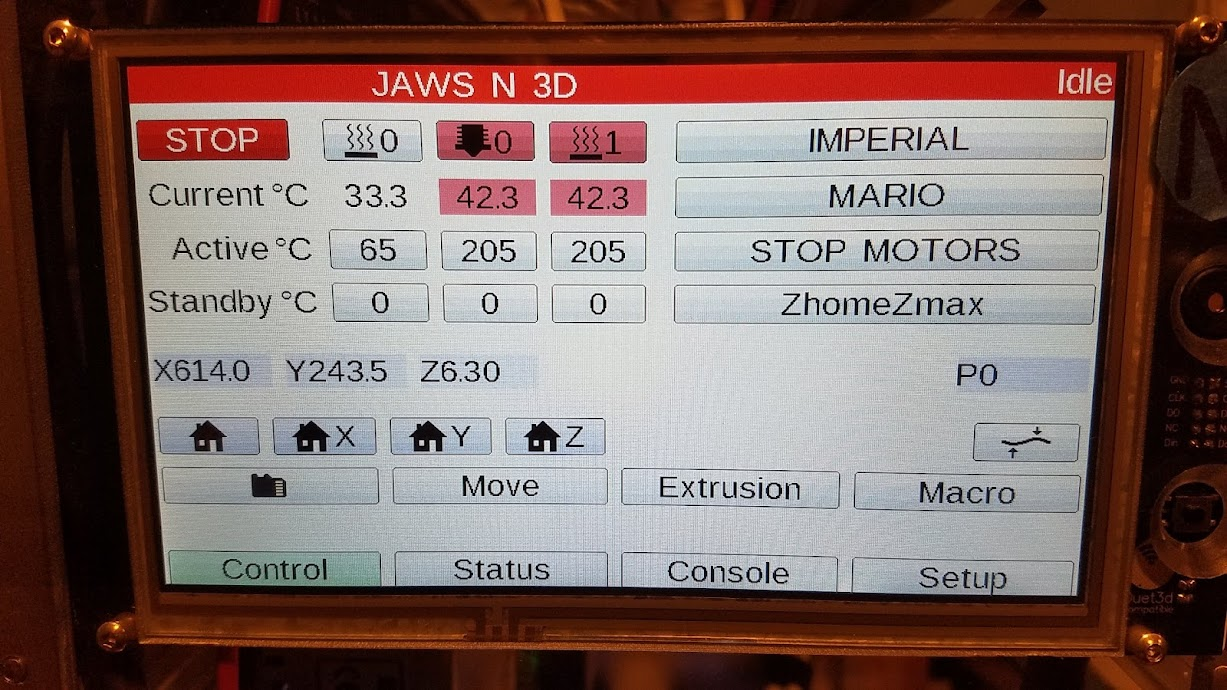

You can use the DWC Object Model viewer to verify the operation of your endstop sensors.

For example:

Frederick

-

@fcwilt

Homing has been good since I finished the new rrf3+ syntax...only in the last 2 weeks ive had it bounced off of and jamming into the end stops a few times before I ever even commented out the m-84...

It actually seems to be doing that more and more.

which is why we're going to at least swap to a different SD card for further testing. -

@jawsn3d do you have any tool change files? You are running T0 before you run G28, so maybe there is command in tpre0.g or tpost0.g that is failing and aborting the print because an axis hasn't been homed. In RRF3.3 and later, tool change files are run regardless of the homed status.

-

@dc42

I'll post those momentarily but i believe they are setup properly.

i probablt shouldnt have started futzing with that stuff since im still only using 1 tool and it defaults to T0 iirc.

its pretty much just comments since i was trying to see what would show on the paneldue before i got the "print finished " notification which pops up before start.g finishes; tpre0.g ; called before tool 0 is selected ; ; generated by RepRapFirmware Configuration Tool v2.1.5 on Sun Jan 12 2020 13:37:35 GMT-0600 (Central Standard Time) M117 "tpre0 called for"; tpost0.g ; called after tool 0 has been selected ; ; generated by RepRapFirmware Configuration Tool v2.1.5 on Sun Jan 12 2020 13:37:35 GMT-0600 (Central Standard Time) ; Wait for set temperatures to be reached M116 P0 M117 "tpost0 called for"; tfree0.g ; called when tool 0 is freed ; ; generated by RepRapFirmware Configuration Tool v2.1.5 on Sun Jan 12 2020 13:37:35 GMT-0600 (Central Standard Time) M117 "tfree0 called for" -

well gentlemen, i believe ive narrowed further the issue.

new sd card, reloaded all of 3.3, same issue every time.did a buncha trial and error, and, after commenting out g28 in start.g....and making sure i was parked back at the origin after homing all axis individually.

the print is under way.same pause at the m117 "g28 begins" comment (g28 disabled)...but proceeded to print after displaying "start.g ends printing should begin"

so somehow after the g28 calls homeall we have it kick out that print finished notification.

i cant see anything out of place but at least i feel safe enough to manually home and start enabling some playtime with g32/g29 and our 4 z screws.

still cant figure out how i have a bed thats tied to the hotend temps/control....but at least i have a cube!

-

@jawsn3d So we know the cause of the error is in the homeall.g file. The next thing would be to comment out parts of it to see exactly where about in the file the error is. One thing I notice is that your homeall file has this:

M280 P0 S160 I1 ; Re-Set the probeI don't use a Bltouch so I can't be of much help. But in the wiki, the comments for M280 state this - quote:

"RRF3: The I parameter is no longer supported in M280. Instead, specify an inverted pin name in M950 when you create the GPIO port."

So your M280 should not have that "I1" parameter. Whether that could be the cause of your issue, I cannot say.....

-

@jawsn3d please post your homeall.g file.