Config for the Pinda v2 ,need help!

-

@lui2004 sorry I am Bulgarian .

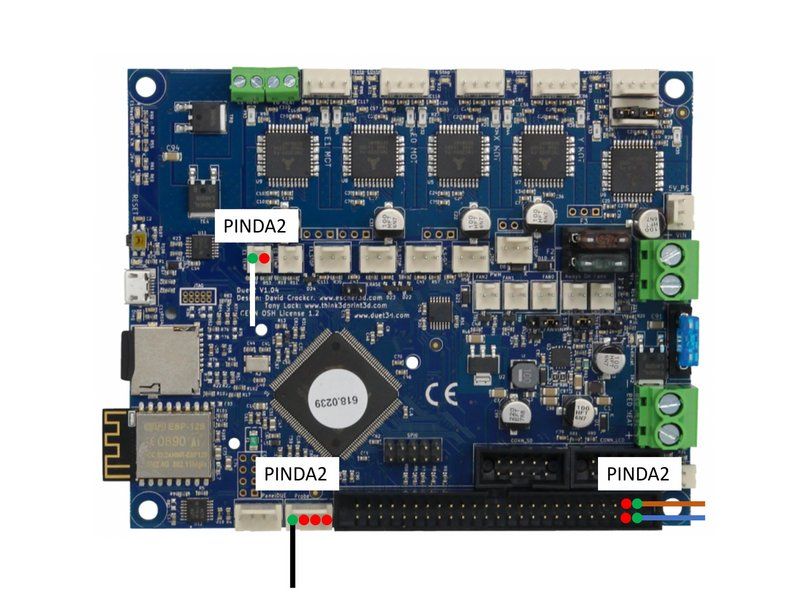

So generaly you ahve 3 wires +5V,- and Signal.- and Sig are conected to - and sig on probe conector and 5V to some 5V pin on the board

-

@martin7404 like this:

and config:

; PINDA2

;

M558 P5 C"zprobe.in" H1.5 F1000 T12000 A3 ; set Z probe to PINDA2

M308 S2 P"e1temp" A"Pinda V2" Y"thermistor" T100000 B3950 ; temperature of PINDA2 -

@lui2004 that looks correct and the config matches the wiring. As always when you test the trigger for the first time first confirm not is triggering as expected by manually lowering the Z axis so it's not the expected trigger height and checking the z probe is shown as switching in DWC

-

-

@lui2004 if you move the probe down manually do you see the Zprobe indication on DWC change. What is it showing?

-

the pinda wont trigger because i have a pei surface.

i have insert some Aluminum foil under the pei i now it will work.

which surface is good without Aluminum foil under pei ?

-

@lui2004 whats the PEI surface mounted on? I suppose most people using PINDA style probes an aluminium bed.

-

aluminium bed with pei

this is my heightmap:

RepRapFirmware height map file v2 generated at 2021-10-12 14:59, min error -0.093, max error 0.125, mean 0.003, deviation 0.049 axis0,axis1,min0,max0,min1,max1,radius,spacing0,spacing1,num0,num1 X,Y,10.00,220.00,10.00,220.00,-1.00,20.00,20.00,11,11 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0 0, 0, 0, 0.008, -0.000, 0.091, 0.057, -0.005, 0.050, 0.050, 0.007 0, 0, 0, -0.000, -0.025, 0.082, 0.087, 0.050, 0.032, 0.091, -0.009 0, 0, 0, -0.018, 0.025, 0.116, 0.125, 0.012, 0.007, 0.082, -0.025 0, 0, 0, -0.025, 0.016, 0.116, 0.125, -0.018, 0.032, -0.005, -0.050 0, 0, 0, -0.043, -0.025, 0.041, 0.025, -0.009, -0.018, 0.025, -0.084 0, 0, 0, -0.050, -0.075, -0.034, -0.018, -0.000, -0.000, -0.000, -0.059 0, 0, 0, -0.050, -0.038, -0.034, -0.021, -0.018, -0.018, 0.037, -0.059 0, 0, 0, -0.055, -0.050, -0.043, 0.025, -0.018, -0.034, -0.055, -0.093 0, 0, 0, -0.063, -0.034, 0.032, 0.025, 0.016, -0.009, 0.020, -0.050 0, 0, 0, -0.030, -0.025, 0.007, -0.000, 0.025, 0.025, 0.050, 0.041 -

I bought a new surface !

what is important to calibrate the pinda V2 ?

-

This is my actuall config.g

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"Ender 5" ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Physical drive 0 goes forwards M569 P1 S1 ; Physical drive 1 goes forwards M569 P2 S0 ; Physical drive 2 goes backwards M569 P3 S1 ; Physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E288.30 ; set steps per mm M566 X600.00 Y600.00 Z60.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z600.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1400 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X235 Y235 Z250 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;Filament Sensors M591 D0 P2 C"!e0_stop" S1 ;Extruder 1(0) ; PINDA2 ;M558 P5 C"^zprobe.in" H1.5 F1000 T12000 A3 ; set Z probe to PINDA2 M558 K0 P8 C"^zprobe.in" I1 H2 F1000 T6000 A20 S0.005 ; set Z probe type to effector and the dive height + speeds, max number of probes per point, tolerance(MM) M308 S2 P"e1temp" A"Pinda V2" Y"thermistor" T100000 B3950 ; temperature of PINDA2 G31 P500 X52.7 Y18 Z1.775 ; set Z probe trigger value, offset and trigger height M557 X10:210 Y10:210 S20 ; define mesh grid ;M557 X41.2:219 Y15:195 S20 ;M671 X28.8:198.8:198:28.8 Y24:24:194:194 P0.5 M557 X10:220 Y10:220 S20 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 300C M307 H1 B0 S1.00 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 S3D G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled ; Custom settings are not configured M575 P1 S1 B57600 ; enable support for PanelDue M572 D0 S0.05 ; Pressure Advance PLA ;M572 D0 S0.08 ; Pressure Advance PLA M207 S1.50 R0 F2100 T2100 Z0 ; Firmware Retraction P0 S0.45 R0 F2100 T2100 Z0 ; Firmware Retraction M204 P500 T2000 T0 ; Sets Tool0 as default M501homeall.g

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Jul 28 2020 08:52:12 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative mode G1 H2 Z4 F200 ; raise head 4mm G1 H1 X-240 Y-240 F3000 ; move up to 240mm in the -X and -Y directions until the homing switches are triggered G1 H2 X4 Y4 F600; move slowly 6mm in +X and +Y directions G1 H1 X-10 Y-10 ; move up to 10mm in the -X and -Y directions until the homing switches are triggered G90 ; back to absolute mode G1 X57.3 Y92 F2000 ; put head over the centre of the bed, or wherever you want to probe G30 ; lower head, stop when probe triggered and set Z to trigger height; homex.g

; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) G91 ; relative mode G1 H2 Z4 F200 ; raise head to avoid dragging nozzle over the bed G1 H1 X-240 F3000 ; move up to 240mm in the +X direction, stopping if the homing switch is triggered G1 X-4 F600 ; move slowly 4mm in the -X direction G1 H1 X10 ; move slowly 10mm in the +X direction, stopping at the homing switch G1 H2 Z-4 F200 ; lower the head again G90 ; back to absolute modehomey.g

; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) G91 ; relative mode G1 H2 Z4 F200 ; raise head to avoid dragging nozzle over the bed G1 H1 Y-240 F3000 ; move up to 240mm in the -X direction, stopping if the homing switch is triggered G1 X4 F600 ; move slowly 4mm in the +X direction G1 H1 X-10 ; move slowly 10mm in the -X direction, stopping at the homing switch G1 H2 Z-4 F200 ; lower the head again G90 ; back to absolute modehomez.g

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Jul 28 2020 08:52:37 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X57.3 Y92 F6000 ; go to first probe point G30 ; home Z by probing the bedthanks for help

-

Hi

Is there a how to ,to set z offset on different temperature? Like in marlin?

-

@lui2004 there is not the option of using a table like i think Marlin has. You configure the S and C parameters within G31 to compensate:

https://duet3d.dozuki.com/Wiki/G31Based on this thread:

https://forum.duet3d.com/topic/16972/pinda-2-probe-with-temperature-compensation/5?_=1593546022132It appears the non linearity of the measurements at different temperatures could be a problem.

The poster in that post shows a conditional gcode way to get around the problem. Before you do that it would be worth testing you can get a good z probe performance with everything (including the PINDA temperature) at a steady temperature.

Once thats working then non linear temperature compensation can be looked at,

-

Thanks ,i will give it a try!

Other question when print is finished my z axis at 0 what i can do that the z-axis goes u after print?

-

@lui2004 in the end gcode you can add a move to lift slightly and move the tool out the way.

E,g,

G91 ; set to relative positioning G1 Z5 ; raise Z 5 mm G90 ; set to absolute positioning G1 X0 Y0 ; park at X0 Y0