Extruder motor suddenly getting extremely hot

-

@dc42 ...in the meantime:

Would it help to repeat the current settings periodically? (eg. at layer change, add the M906 in slicer or let daemon.g repeat it every 10sec.) -

@o_lampe said in Extruder motor suddenly getting extremely hot:

@dc42 ...in the meantime:

Would it help to repeat the current settings periodically? (eg. at layer change, add the M906 in slicer or let daemon.g repeat it every 10sec.)Probably not.

I have the new firmware ready.

-

@dc42 said in Extruder motor suddenly getting extremely hot:

https://duet3d.dozuki.com/Wiki/Getting_Started_With_Duet_3#Section_Software_Installation

I am upgrading now the latest beta release. If you can send the firmware then I can test is.

However, the plot thickens. Now as one would expect, I haven't had the error after I reported it here. But there is a new issue that may or may not be related.

At a random point in the print the heater temp goes to 2000 degrees. But... the printer does not stop printing. It just continues as nothing has happened. No errors, nothing in the logs but also no extruder moves. Hotend cools down but fans stay on (even thermo-controlled one).

When I pause the print I can still communicate with the toolbar with M115 B121. I can even reset it with M999 B121. But no change.

But if I do a M999 for a full reset suddenly the temp is back to normal, fans, power down and all is well.After the reset the log reports this:

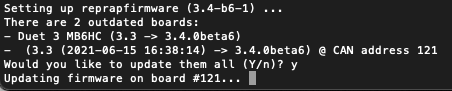

Error: Failed to switch off remote heater 1: Board 121 does not have heater 1edit: Hmm, maybe this has something to do with it. I just did the upgrade but is has been on this for 10 minutes now:

-

@hbm-3d the upgrade should happen quickly. Reset the main board if you haven't already.

-

@dc42 All running now on beta6 but same issue with the temp and toolbar not responding mid-print.

-

@hbm-3d you can find the updated firmware at https://www.dropbox.com/sh/wtgcvkuaq52x3aq/AAADVEzSwypcIZSwExX0M4RQa?dl=0.

What type of temperature sensor are you using on the tool board (the one that reports 2000C)?

-

@dc42 I use the standart E3D thermistors.

Today I had to do a short print (25 minutes) so i figured it was that short that it will probably make before the error would occur. Sadly no.Here are the results.

First print:

It started like normal and then it went into overdrive. It looks like it is extruding more than it should.

I restarted it again and then it went into overdrive straight from the start.

As you can see, major over extrusion. The extruder motor was burning hot.But now the kicker. I reset the printer again and printed the same file. The only exception was that I did not use Simplify but SuperSlicer.

I used a standard Voron preset without optimisation because I haven't used the slicer yet. I always use Simplify.I had a 12 hour print that i have tried to print now for 4 times. Every time it failed with either temp sensor error or this overdrive error.

Now I resliced it with SuperSlicer (just default non-optimised Voron preset) and it is now almost done without issues...I have no idea what is going on here...

edit: The 12 hour print failed after 10,5 hours with the temp error again. I'm really considering ditching the toolboard en going back to a full wire loom to the toolhead.

-

@hbm-3d have you installed the updated firmware that I linked to yet?

-

@dc42 I did after the last failure. Running the 12 hour print again now.

-

Did the update. Print failed again. Temp error, no errors, no log entries, printer kept on going. Reset the printer without touching it and temp is good again.

If it is a cable break or a sensor defect it would not be fixed by just a software reset. -

@hbm-3d said in Extruder motor suddenly getting extremely hot:

As you can see, major over extrusion. The extruder motor was burning hot.

Are you absolutely certain that is not under extrusion?

A failing heater (or power to it) or a partly blocked nozzle etc. could also explain the extruder motor getting hot, as its overloaded.I'd expect over extrusion to result in a fairly solid surface with grooves plowed by the nozzle, to the point the axis drives overloaded & lost positions.

-

@rjenkinsgb I don't think it is under extrusion. As you see in the second picture, the Sideview, it starts with a neat layer stacking but when it goes into overdrive you see that it expands beyond the layers beneath. That is a sign of overextrusion. And in the pictures below that you see the plowing happening.

I do agree that that is what may increase the motor temp. It tries to push so much plastic and the hotend can't melt it that fast. Plus the nozzle will get blocked due to the amount of plastic beneath it. But not due to under extrusion.

Besides of it it a temp issue or not, the printer should signal it and stop but it doesn't.

-

undefined Vinculum referenced this topic

undefined Vinculum referenced this topic

-

Well i need the machine to work so I ripped the toolboard out of my home printer and just layed a lot of wires. Problem fixed.

But now, I wanted to use the toolboard as an upgrade to my work printers. Totally different design. But similar 6HC mainboard and a new 1LC toolboard. This time a v1.2. Guess what? Same issue!

Start great and suddenly it goes into overdrive.I made a cross post in this topic (https://forum.duet3d.com/topic/26697/toolboard-1lc-heater-falut-mid-print/7?_=1641814629460) where someone has at least part of the symptoms I have. Here is what I had this morning:

Had a 88 hour print and it failed midway. Temp sensor says 2000 degrees but the printer doesn't go into error mode, it just continues.

I then stopped the print, decoupled the thermistor and connected a brand new one. Temp still at 2000.

Reset just the board with the 2 buttons, no effect. Reset the board with M999 B121, no effect. Unplugged the power from the toolboard, no effect.

Only after pressing the reset button on the 6HC it came back online and with the original temperature sensor...

All run the same firmware, 3.4.0beta7.That was this morning. I then did a restart of the print and the result is above. Again 2000 degrees, printer goes into overdrive and print failes. But printer still keeps on moving...

-

@hbm-3d I'm not so involved in this so please feel free to tell me to butt out...

In the picture you show, that looks a lot like an overheated print (which may also have overextrusion). I note that it starts where the print changes from a large infilled section to a thinner section. Is this seen in your other larger test prints? Given the 2000C thermistor it seems there is something going on with temperature control?

I believe it is a current firmware limitation that heater faults on expansion boards are not reacted to. You can however query them via the object model (I think?) so could run your own checks via daemon.g for the meantime. I think this is planned to be fixed in RRF3.5 (check the firmware limitation Wiki page for more details).

I wonder if the reason you need to reset the 6HC is because the toolboard loses its config, so you need to run config.g again. Maybe try just calling M98 P"config.g" next time to see? Might help narrow down the debug options

-

@hbm-3d

I'd guess you have a CAN bus problem; interference from other wiring, bad termination or a bad connection, so some data is being corrupted and causing the system to misbehave.A power brownout that did not cause a full reset at the toolboard could also give a similar effect, again possibly a bad connection somewhere?

Are the CAN connections either twisted pair in each run, or well separated from other wiring ?