Which frame design can scale best?

-

@kuon said in Which frame design can scale best?:

As for the Z axis, I thought of using belts if I go belts, and depending on what motor I use, I will put brakes/worm gear.

Here is a quick-and-dirty video of my implementation of a Mark Forged type of printer. The video was made to demonstrate the bed leveling ability of multiple Z steppers.

It was also a test bed for belt drive for the Z axis. Since the Z axis usually doesn't need to be fast but you don't want the bed to fall when power is removed I used steppers with integrated 5 to 1 planetary gearboxes.

I'm so pleased with the result of using belt drive I will likely use it on any new printer I build.

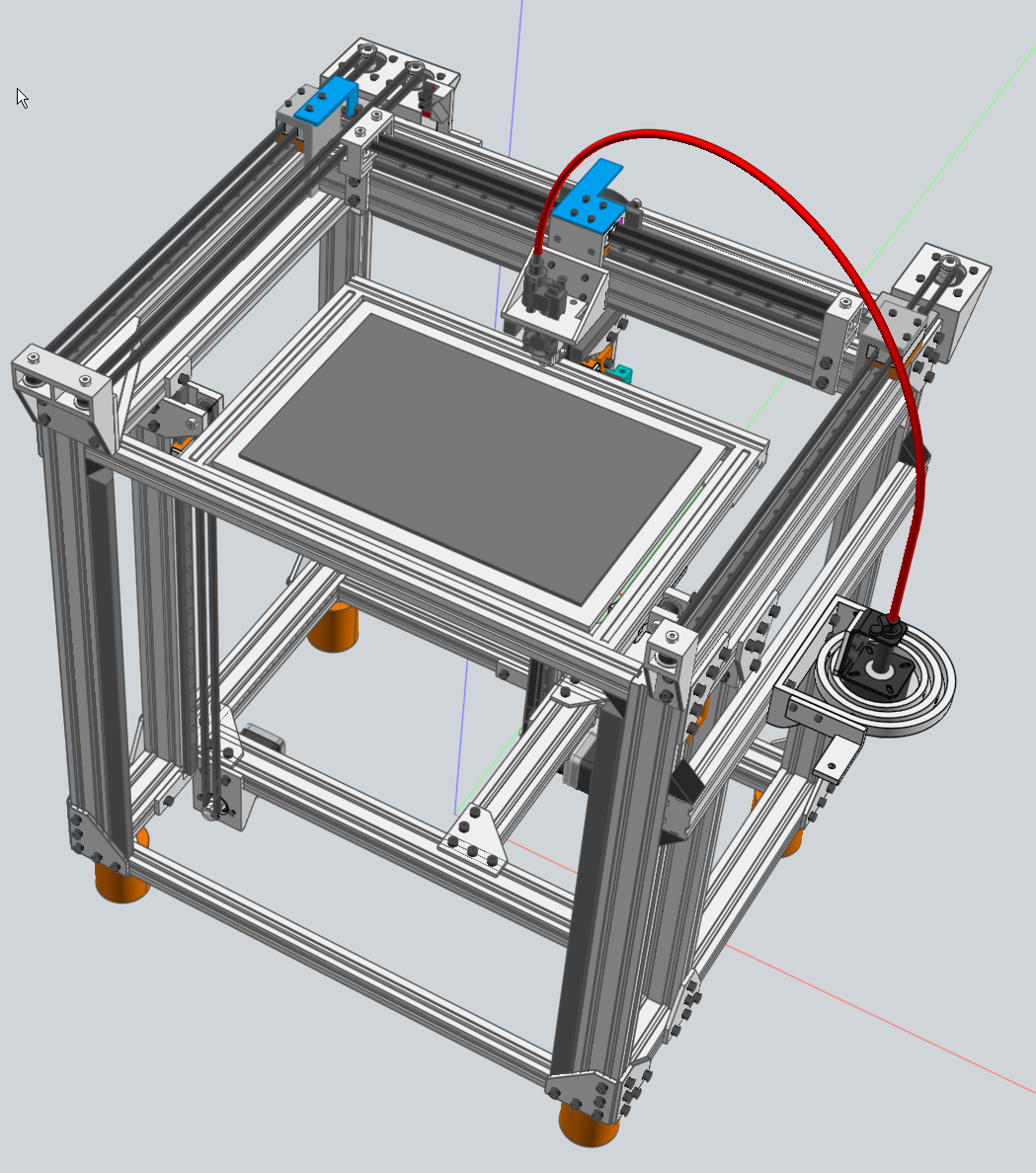

Here is a overview of the printer which better shows the Mark Forged kinimatics:

-

@kuon I used one of these in my printer's belt lifted Z axis and it works very nicley: https://www.ebay.com/itm/191714031261?epid=711126295&hash=item2ca30bf69d:g:A7UAAOSwPhdVB2f0

The gears are about as good as you can get, don't create any print artifacts, and the 30:1 ratio prevents bed drop when power is cut. With the pulleys I used it provides a nice, round, 20 um/full step.

The problem with planetary gear reductions is they usually (always?) have very odd gear ratios that make it impossible to print layers in full step multiples (in case that matters to you). Here's a classic example:

https://www.ebay.com/itm/231616316474?epid=1540009596&hash=item35ed68843a:g:B9wAAOSw9N1VmkMZ

As Tom Waits says, "The large print giveth, and the small print taketh away". The big print says it's a 5:1 gear box, but if you look at the specs, it's actually 5+2/11:1. There is no "neat" full-step-multiple layer thickness available with that. I would be wary of any planetary geared motor that provides only the big print number without seeing a detailed spec sheet that shows the actual ratio.OTOH, maybe it isn't really necessary to print layers in full-step multiples.

Someone at the makerspace built a corexy printer with a belt lifted Z axis using this type of motor/gearbox and it produces beautiful prints: https://www.aliexpress.com/item/1005001763231566.html?spm=a2g0o.productlist.0.0.1b0c182eqynHM6&algo_pvid=29493bf2-624e-4829-882a-4d4b452de7ce&algo_exp_id=29493bf2-624e-4829-882a-4d4b452de7ce-41&pdp_ext_f={"sku_id"%3A"12000017469607760"}

-

@mrehorstdmd said in Which frame design can scale best?:

The problem with planetary gear reductions is they usually (always?) have very odd gear ratios that make it impossible to print layers in full step multiples (in case that matters to you).

You are correct in that they often have odd gear ratios but you can find them in ratios that may be preferred. The cheaper ones I tried at first just as proof of concept had a ratio like you mentioned. But once I was satisfied that the concept was sound I researched more expensive units and found true 5 to 1.

Frederick

-

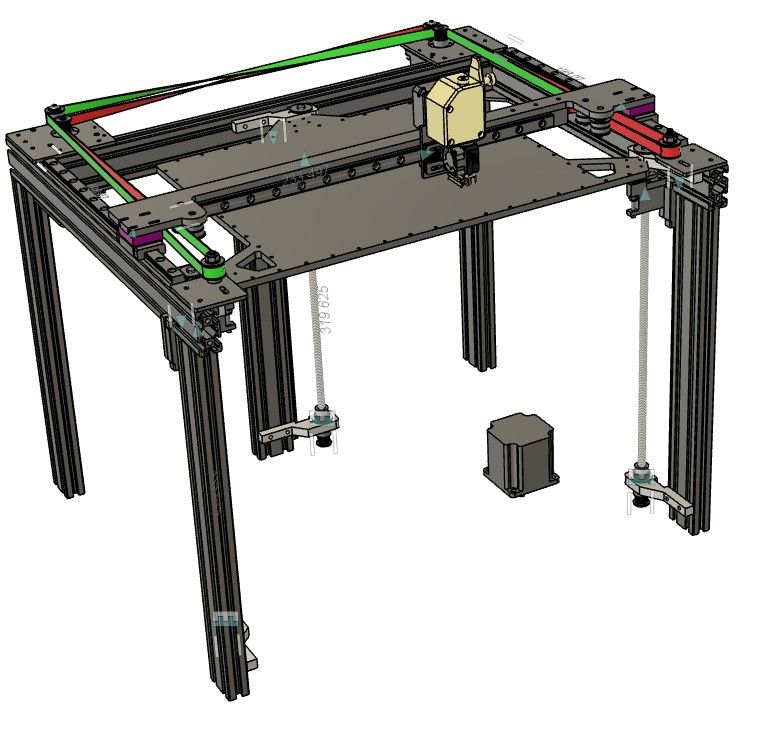

Very interesting discussion topic. I'm working on a printer design myself, and although it's not the large scale you are thinking about I've designed it without any restrictions on X Y or Z. At present its capacity is 250 x 300 x250 tall), Its a coreXY with a "twisted belt" design. I've worked hard to minimize belt offsets form rail axes for both the X and Y rails. My belief is that minimum offsets lead to minimum moment arms and therefore minimal torques during acceleration and deceleration. I've also designed to not require machined parts (so far, so good) but rely heavily on metal plates that can be laser cut (there are lots of laser job shops, my favorite is sendcutsend.com in the us - no affiliation, just a satisfied customer). It's still a work in progress, as you can see. I've built a proto top frame I'm happy with and I'm working on the Z axes now. However, the Mark Forged kinematics are vert intriguing. I might have to build one of those too...

-

-

@mikeabuilder I would love to be able to source steel easily, but here in switzerland I couldn't find a reasonably priced service that does precision steel cutting.

-

@fcwilt If I do not use the "crossed gantry" (ala ultimaker), I could also use an IDEX arrangement instead of one large head, but this would mean 2 moving steppers along Y. I need dual head, but not necessarily dual carriage.

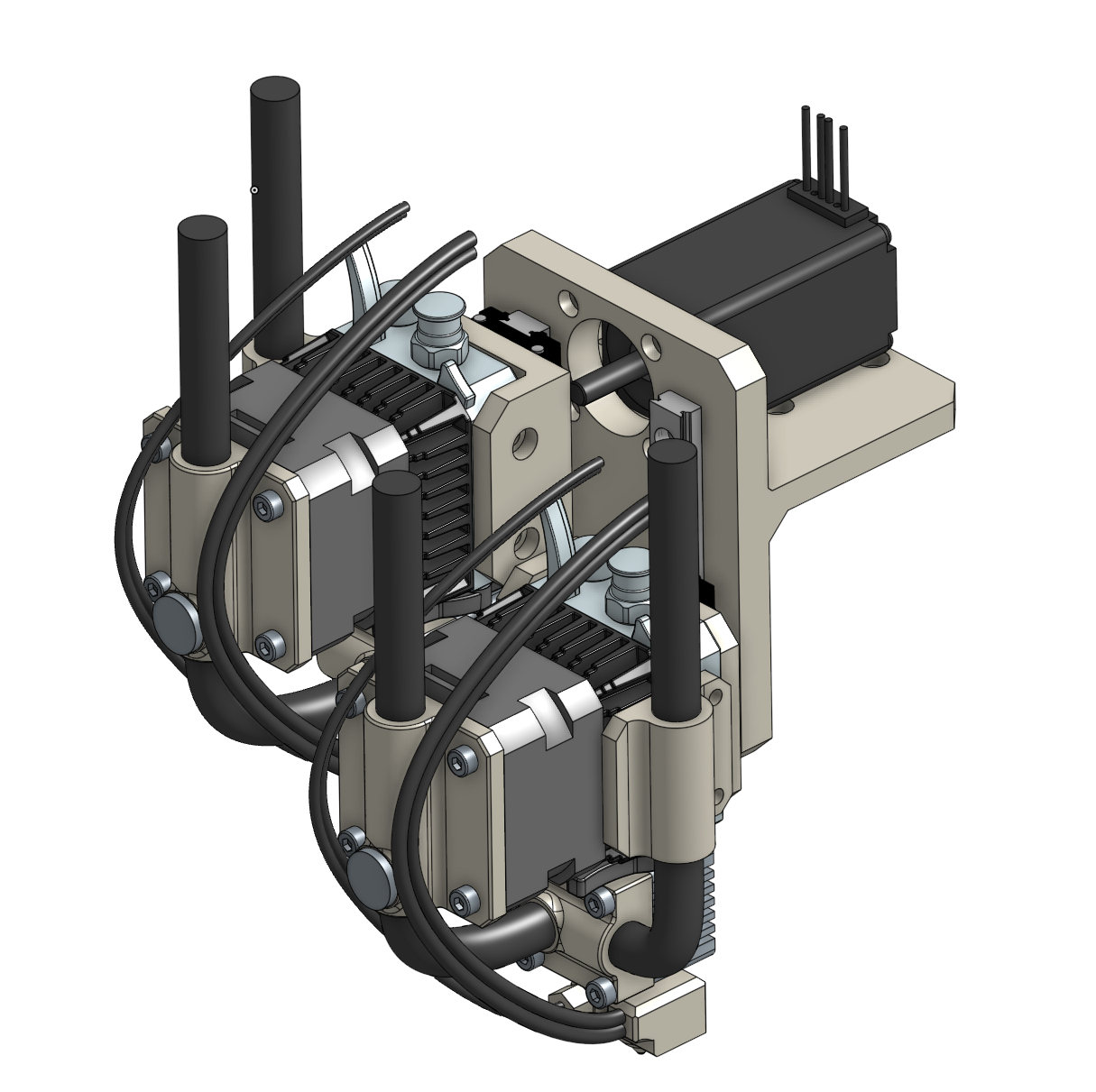

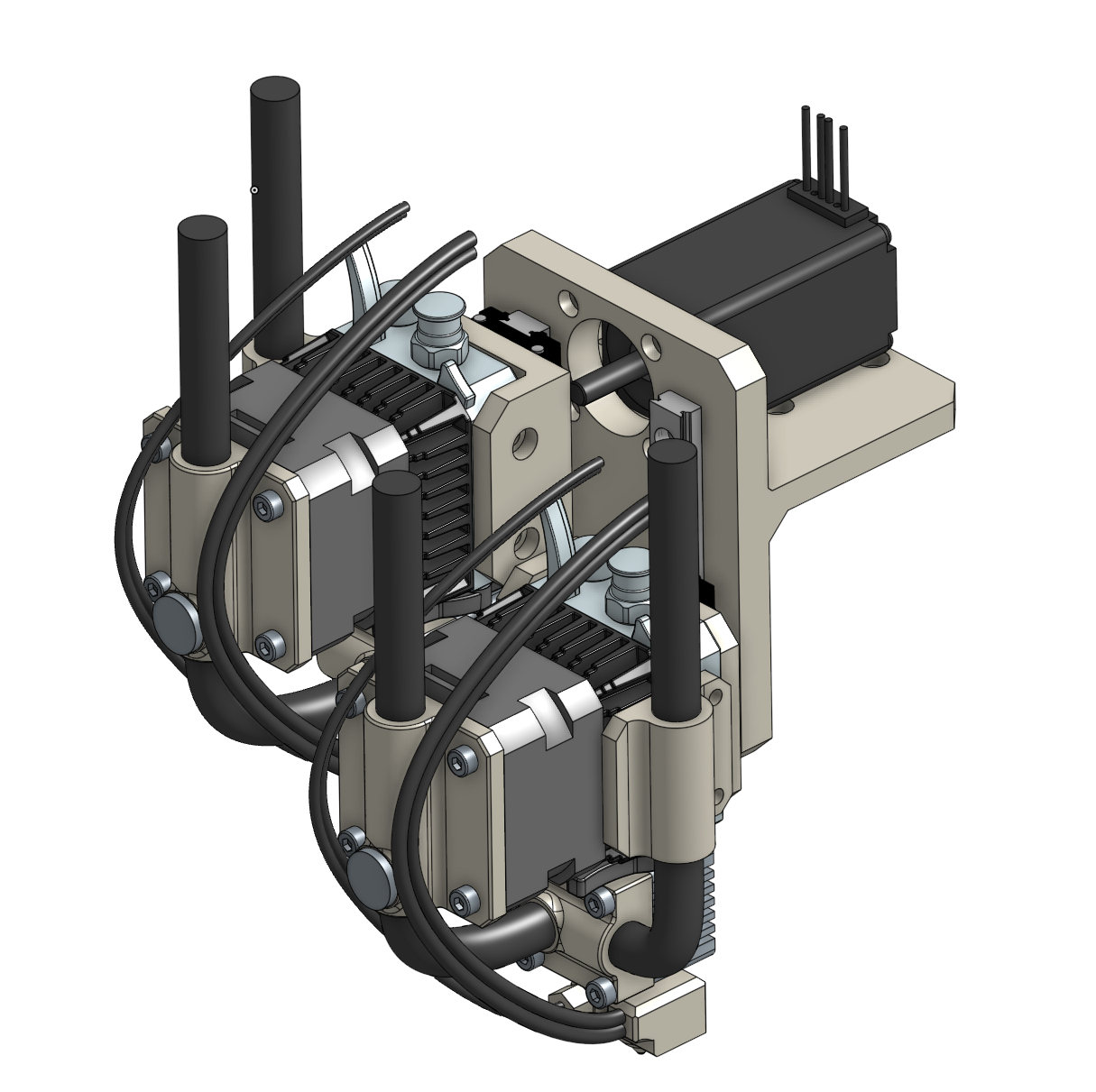

I am still "tinkering around" but I thought of maybe using a small stepper with a rack gear to be able to lift either extruder. The following picture is just the placement, rack gear or mini belt is not present yet. Basically for probing both extruders would be in the middle position, and for printing either one would be down.

The advantage of moving one large head is that I could mount anything (pellet...) and for a large printer, it is a plus.

I love the mark forged kinematic idea, but it makes one belt very long, that's not an issue for a large printer?

-

@kuon said in Which frame design can scale best?:

I love the mark forged kinematic idea, but it makes one belt very long, that's not an issue for a large printer?

You mean the X belt?

At the time I was deciding between a CoreXY and the Mark Forged. Everyone seemed to be doing a CoreXY so I decided to be difficult - I mean different.

I never considered the X belt to be that long. I did opt for 9mm belts instead of 6.

Frederick

-

@kuon said in Which frame design can scale best?:

I am still "tinkering around" but I thought of maybe using a small stepper with a rack gear to be able to lift either extruder. The following picture is just the placement, rack gear or mini belt is not present yet. Basically for probing both extruders would be in the middle position, and for printing either one would be down.

What are those largish black rods for?

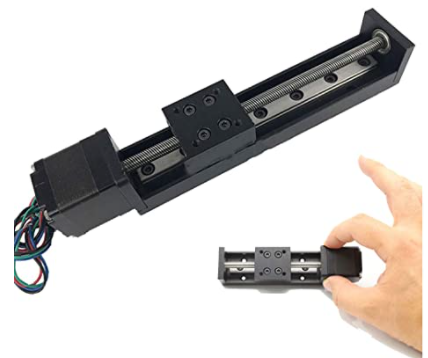

I used one these in 50mm for a recent project:

-

@fcwilt Yeah, for my frame size it is nearly a 6 meter belt. That's why I am considering a regular cartesian printer (like the craftbot flow serie), and thus maybe IDEA. At first I thought the ultimaker crossed gantry would be cool, as it allows for short belt (I would have used 4 steppers, 2 per axles).

-

@fcwilt Black rods are water cooling pipes for "illustration".

-

@kuon said in Which frame design can scale best?:

@fcwilt Yeah, for my frame size it is nearly a 6 meter belt. That's why I am considering a regular cartesian printer (like the craftbot flow serie), and thus maybe IDEA. At first I thought the ultimaker crossed gantry would be cool, as it allows for short belt (I would have used 4 steppers, 2 per axles).

The original cross-gantry setup was rather elegant in that it used two round rounds, as both guides and support, for the crossed part. That only works for small printers. For your size you would need to use linear rails mounted to something like a metal plate or extrusion to prevent gantry zag.

The cross-gantry I experimented with used 4 steppers which worked very well - smooth, quiet and very fast.

I'm a fan of the design and may well finished building the printer after I finish the one I am working on now.

Frederick

-

@fcwilt What I like with the cross gantry is that I can have stationary steppers and short belts (with 4 steppers). Of course I would use a heavy "X" with profiles with linear rails on them instead of rods.

-

Then you should go with cross gantry.

The short belts are a plus.

And as long as you don't mind the extra mass of the cross I believe you would be happy with the result.

To keep down moving mass on my printers they are all equipped with Zesty Nimbles as you can see in the image I posted.

Frederick

-

@fcwilt Well, with the cross I can put steppers as big as I want as I will not move them. As for non direct drive, I want to keep the option open for a pellet extruder which weight roughly the same as my dual extruder head pictured above.

-

@kuon said in Which frame design can scale best?:

@fcwilt Well, with the cross I can put steppers as big as I want as I will not move them. As for non direct drive, I want to keep the option open for a pellet extruder which weight roughly the same as my dual extruder head pictured above.

Pellet Extruder???

Frederick

-

-

@fcwilt Yeah, like this https://dyzedesign.com/pulsar-pellet-extruder/ I want this printer to be a platform were I can experiment. And I want my gantry to be able to handle this weight (even if I would print slowly with that).

Of course that extruder is overkill (and expensive), but there are some other high flow (also 2.85mm filament based, like this https://dyzedesign.com/typhoon-extruder/ ) extruders which weight like 2kg I might try.

Even if I do not plan on using it now, while building a project that large, I'd like to have a gantry that is able to handle other "heads".

-

Wow. You could do amazing things with that beast.

Yes you want to come up with a good design for allowing changing tools - hopefully without a lot of work.

Fun project.

Frederick

-

@fcwilt said in Which frame design can scale best?:

@kuon

Wow. You could do amazing things with that beast.

Yes you want to come up with a good design for allowing changing tools - hopefully without a lot of work.Instead of linear rails for the extruder -mini Z axes, you could use dovetail profiles. They could easily slide out for maintenance or tool changing.

For a light load, I made my own PTFE sliders.