Anybody wants a stepper motor analyzer?

-

@dogma2k, that sounds bad. Everything should work.

- Did you make any hardware changes to the board?

- Are you the exact same components in the original schema?

- What TFT module are you using?

- What version of the firmware UF2 file do you use?

The original schema is here

https://github.com/zapta/simple_stepper_motor_analyzer/blob/main/kicad/stepper_analyzer.pdfThe original firmware is here

https://github.com/zapta/simple_stepper_motor_analyzer/releases/download/F1.0.4/APPLICATION.uf2If you want, you can send me one analyzer (to the US) and I will look at it and send you back.

-

@dogma2k is your PSU powerful enough to supply current to all 4 Picos and LCD screens? Colour TFT screens draw quite a lot of current.

-

@dc42

I hope so. Both PSU have 5V/DC 5A -

Anyone have an idea? Something like soldering a diode?

It would be a shame if I had to take it all apart again because it doesn't work

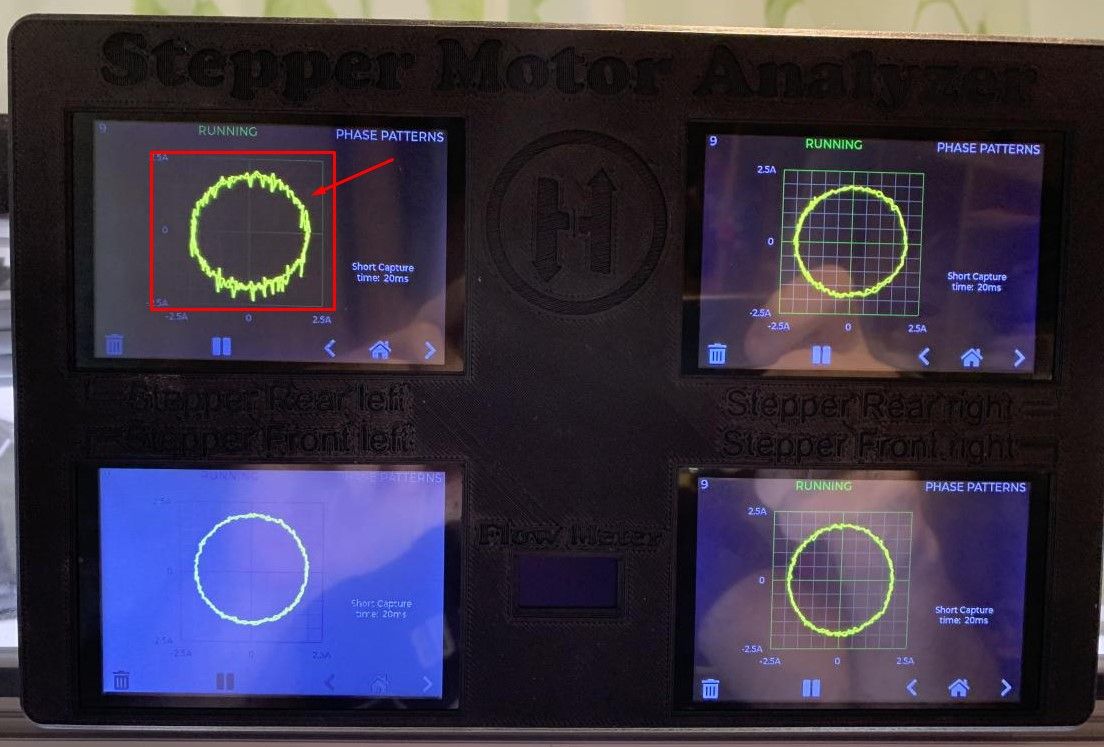

PS it may be that an analyzer is defective (or the engine). Yes, I know I didn't zero it

-

@dogma2k said in Anybody wants a stepper motor analyzer?:

Anyone have an idea?

What cable or cables are you using to power them?

A lot of cheap USB cables are really for data only and have ludicrously thin cores for the power connections, causing serious voltage drops as soon as you try to run anything that takes significant current.

I've even had ones advertised as "high current" / "Heavy duty" that will not run USB devices that need 200 - 300mA.

Oddly enough, the early (typically cream coloured) ones I have work fine!

-

@dogma2k, can you swap the connections of two analyzers to see if the problem follows the stepper or the analyzer?

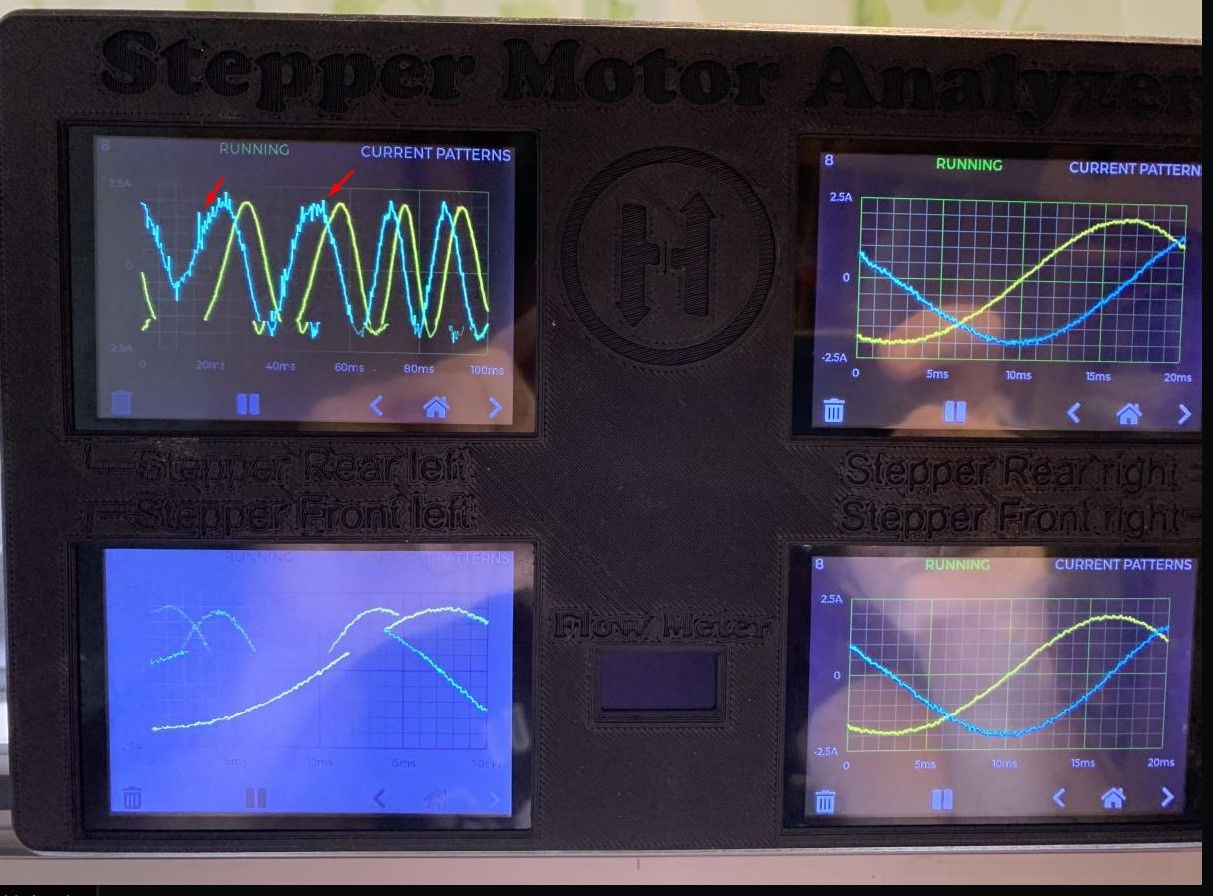

BTW, some of the artifacts, but not the noise you marked with arrows, are due to the screen being refreshed during the camera's exposure. You can pause the analyzer (using the || button at the bottom) if you want to avoid it.

-

@rjenkinsgb

At the moment, the power supply comes from a 5V / 5A power pack with 2x1mm² wires to the analyzer housing. In the housing, USB cables are used to distribute to the analyzers.The cables to and from the analyzer for the motors are LIYCY-OB 4x0.5mm² (i.e. shielded cable)

However, I think that the cross-section of the eagle of the USB cable is sufficient. Because the problem only occurs when more than 2 analyzers work at the same time with active engines (with 3 it gets worse over time)

However, I noticed that if I press a button longer with 4 active analyzers, the display then reacts. Just not with the analyzer at the top left, it even switches back and forth on its own

-

@zapta said in Anybody wants a stepper motor analyzer?:

@dogma2k, can you swap the connections of two analyzers to see if the problem follows the stepper or the analyzer?

I can at least swap the analyzers to see if the noise moves with it. But only tonight

BTW, some of the artifacts, but not the noise you marked with arrows, are due to the screen being refreshed during the camera's exposure. You can pause the analyzer (using the || button at the bottom) if you want to avoid it.

That with the II is a good tip.

Another question, I just have the APPLICATION.uf2 from https://github.com/zapta/simple_stepper_motor_analyzer/tree/main/temp

taken and copied. Is this still a beta version or is it already stable? -

@dogma2k , I am not sure what is in that temp dir.

This is the latest stable release of the firmware

https://github.com/zapta/simple_stepper_motor_analyzer/releases/tag/F1.0.4

-

@zapta

So the artifacts with the analyzer. So I can actually rule out everything else.

If I disconnect the stepper with the noise and only have the 3 other analyzers in operation, there are no problems (regardless of whether the steppers are on or off).

Did I possibly break a current sensor while soldering or simply get it defective?P.S. Thx for the link

-

@dogma2k, it's not clear from 'only have the 3 other analyzers in operation' if you tried to monitor the motor that had noise with another analyzer.

Please try this two cases:

-

Operate the analyzer that gave you noise with another motor in and see if you still see noise with the new motor.

-

Operate the motor that gave you noise with another analyzer and see if you still see noise with the new analyzer.

This tell us if the problem is related to the motor and its driver or to the analyzer.

-

-

@zapta

Sry I think the google translator didn't translate it the way I wanted it to.I swapped the analyzer with several analyzers and each time the error (the artifacts) moved with it.

So no matter which stepper or driver is connected to this one analyzer, it always shows artifacts.In addition, I shut down the analyzer with the artifacts and since then there have been no more delays in the other 3 analyzers during printing.

I hope google translates it now understandable

-

@dogma2k said in Anybody wants a stepper motor analyzer?:

I swapped the analyzer with several analyzers and each time the error (the artifacts) moved with it.

So no matter which stepper or driver is connected to this one analyzer, it always shows artifacts.That sounds like some kind of short circuit between the motor side connections and the internal electronics - a faulty current sensor IC or some kind of bridge or shorted pins on the circuit board.

Can you check with a multimeter (on resistance) between the motor connector pins and USB ground, to see if there is an obvious cross-connection, with all cables disconnected?

-

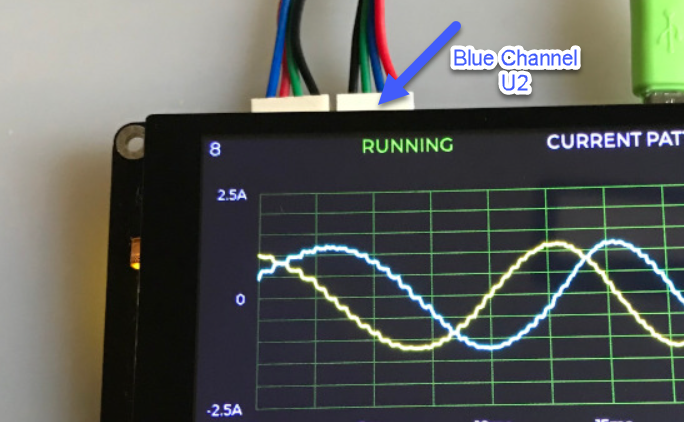

@dogma2k, the blue channel is made of this connector, U2 current sensor, capacitor c2 and the CHB input of the Pico. I suggest to inspect it carefully for anything strange.

Also, when you swap motors and analyzers, if the cables stayed with the same analyzer, I suggest to inspect the cable and connections as well.

-

The cables were always different when I exchanged the analyzer.

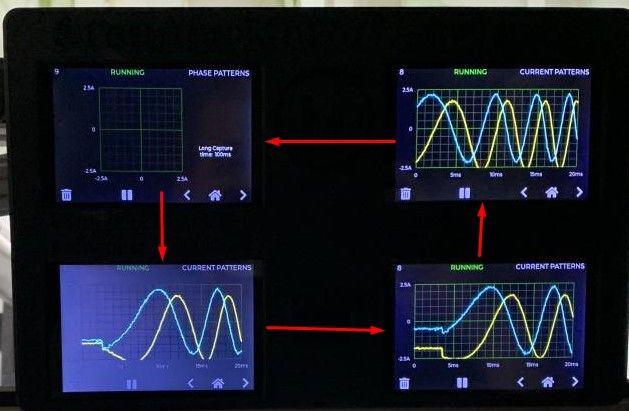

In the picture you can see from the red arrows how I rotated the analyzers (all) and each time the noise moved with it.!!This is an old image and is for illustrative purposes only!!

So start top left -> bottom left -> bottom right -> top right. Thus, the possibly defective analyzer was connected to all possible cables and motors.

As I said, the error has migrated and did not remain at the top left.I'll probably just get a new analyzer. Since I find it strange that if the possibly defective analyzer is not connected, all the other three analyzers work without problems

-

@rjenkinsgb

I thought about that today but didn't find the time.

I'll probably get another analyzer. Then I can calmly check the "possibly defective". -

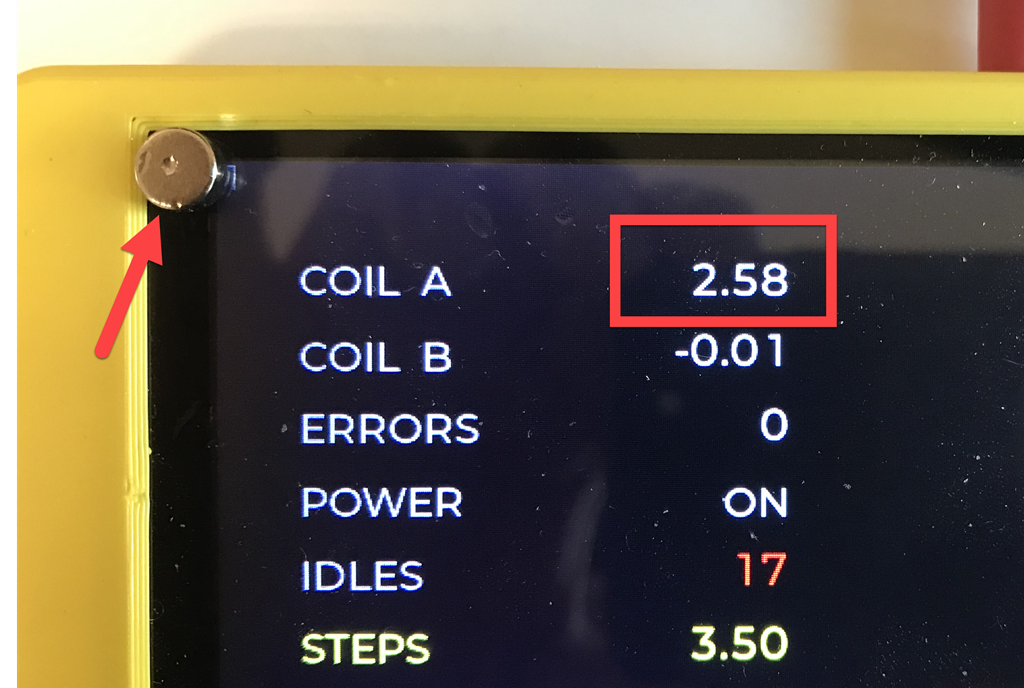

Apparently the analyzer can also be used as a magnetometer. Placing a magnet at the upper left corner gives a reading at Coil A. Positive values means magnet's north pole faces the screen and negative values magnet's south pole.

Useful for example when matching the magnet polarity of a Klicky probe. For higher sensitivity, open the base and place the magnet directly on the sensor.

The current sensor doesn't seems to have memory or hysteresis so I don't think it is effected long term.

-

Hi.

I have made the analyzer using TMCS1101A4B.

It is very nice. Thanks for developing it

I took a video of it in running.

https://youtu.be/eDaxUO8Hbqo?t=115And I have questions.

-

"Current Patterns" and "Phase Patterns" screens are choppy, is this normal?

It sample data for 20ms, but it feels like 2fps.

Is this due to the heavy load of data post-processing on the Raspberry Pi Pico? -

The ACS70331 has a bandwidth of 1MHz, whereas the TMCS1101A4B has a bandwidth of 80KHz.

I think 80KHz is sufficient for measuring stepping motor pulses, is that correct?

-

-

Hi @nyaru, I am glad that it works for you.

- The current and phase pattern, which use signal capturing, have intentional delay between screen updates to allow the user to view the signal. It could update at a higher rate but would be difficult to use.

- The signal is sampled at 100Khz. I am not an expert but by Nyquist–Shannon, 80Khz should be sufficient and maybe theoretically even better than 1Mhz due to lower probability of aliasing. I never used the TMCS1101A4B I believe it should just as fine for this application.

-

Hi @zapta ,I'm currently adapting the schematic and firmware for a different sensor, the MCA1101-5-5 (available on Mouser). They are +-5A, 350 mV/A, 1.5 MHz and they use the SOIC-16 package, but that's not an issue.

The question I have regards the firmware. I've read the source, and to my understanding, I should changestatic const SensorSpec GMR_2P5_SENSOR("G2P5A", 5000, 0.35)inhardware_config.cpp, and possibly the initial voltage offset (or is that handled by the Zero calibration?). I should also change the Y-axis values of many of the graphs, but that's easy. Do I have to adjust anything else? (don't bother reading the datasheet if you don't have time, I just need to know if there are other user-defined parameters or constants).

I'll fork the repo once I'm finished

Cheers!