DUEX 5 V0.8 TO DUEX 5 V0.11

-

@droftarts said in DUEX 5 V0.8 TO DUEX 5 V0.11:

@paolozampini1973 Okay, I'm going to have to stop. I'll try and edit your config.g this evening. I'm available tomorrow.

I still don't think this is a hardware problem. If it is, it's because you are using a clone Duet 2, not one made by Duet3D.

Check that the pins on the expansion connector are not loose or bent over, and properly soldered, on both the Duet 2 and on the DueX (both of them).

If you feel like it, put the v0.8 back on (which is also a clone, not produced by Duet3D).

Ian

Look for me there are no problems anyway I think it's better to go all the way if it's okay with you So we can talk tonight?

-

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

So we can talk tonight?

Probably not, I have ill kids.

Ian

-

@droftarts I am so sorry that you have sick children anyway Many thanks I am sending you the PDF file so we continue tomorrow at least out of curiosity to see how it endsDM860H V3.3 act英文 (1).pdf

-

@paolozampini1973 I have found one piece of information for you this evening, regarding thermistors on V0.11. From https://docs.duet3d.com/Duet3D_hardware/Duet_2_family/DueX2_and_DueX5#pcb-revision-history

Modified the series resistors of the temperature inputs to be 2k2 so they perform better with PT1000 sensors. From RRF3.4 the DueX5 version will be detected and the correct R values set in M308, for RRF 3.3 and earlier use R2200 in the M308 command.

In config.g, change M308 for the following:

M308 S3 P"duex.e2temp" Y"thermistor" T100000 B4138 R2200 ; configure sensor 3 as PT1000 on pin duex.e3temp M308 S4 P"duex.e3temp" Y"thermistor" T100000 B4138 R2200 ; configure sensor 4 as PT1000 on pin duex.e3tempThis should fix the temperature reading. But I think the thermistor configuration is still wrong. What hot ends are you using? Link to where you bought them?

Ian

-

@droftarts said in DUEX 5 V0.8 TO DUEX 5 V0.11:

M308 S3 P"duex.e2temp" Y"thermistor" T100000 B4138 R2200

Good morning the correct TEMPERATURE I had to put R 2150

M308 S3 P"duex.e2temp" Y"thermistor" T100000 B4138 R2150

-

@droftarts

E2 +E3+E4+E5+E6 Filament Sensing it works very well

E2 +E3+E4+E5+E6 it does not work when microswitch is configured There is no way to make it work if I close the led the same collector lights up I connect it in duet and it works is very strange -

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

Good morning the correct TEMPERATURE I had to put R 2150

Use R2200, that's the value of the sense resistor. Don't worry about temperature variation of a couple of degrees at room temperature - thermistors are not very accurate at low temperature. If you use a different R value, they will be inaccurate where it is important, around 200C.

Also, the M308 B value is wrong. I have asked you before, what thermistors or hot ends are you using?

Ian

-

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

E2 +E3+E4+E5+E6 it does not work when microswitch is configured

Please show how you are testing this.

Ian

-

@droftarts NTC 100K ohm B3950

220v 1400W 500*500 NTC 100K 3950

-

@droftarts said in DUEX 5 V0.8 TO DUEX 5 V0.11:

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

E2 +E3+E4+E5+E6 it does not work when microswitch is configured

Please show how you are testing this.

Ian

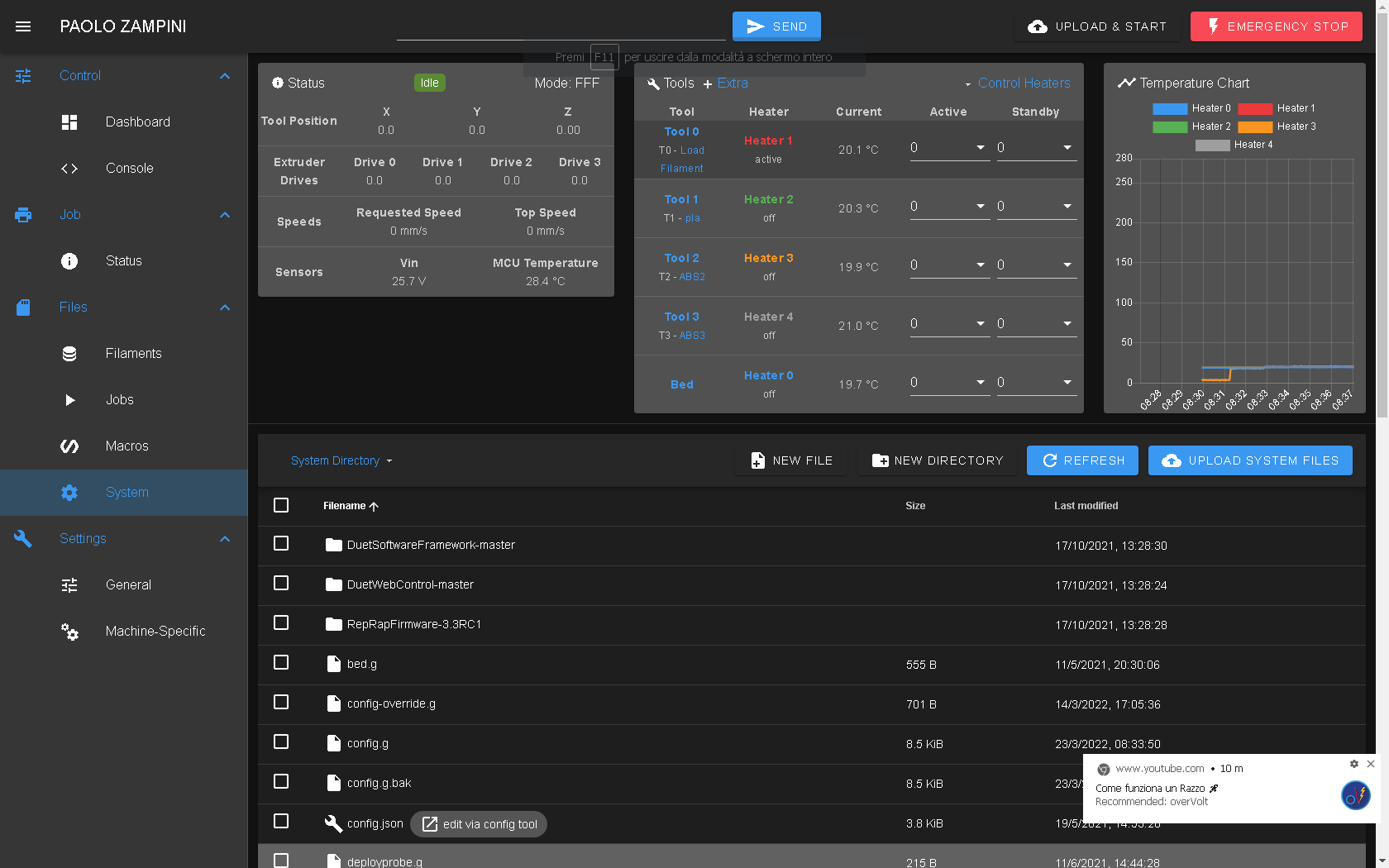

M119

-

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

@droftarts NTC 100K ohm B3950

220v 1400W 500*500 NTC 100K 3950That is the bed. What about the hot ends?

For bed, change config.g to:

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtempIan

-

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

M119

M119 does not show filament sensor status, only endstop status for axes (X, Y, Z).

Send

M591 D#where # is the extruder drive number, 0 to 3.Ian

-

@droftarts said in DUEX 5 V0.8 TO DUEX 5 V0.11:

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

M119

M119 does not show filament sensor status, only endstop status for axes (X, Y, Z).

Send

M591 D#where # is the extruder drive number, 0 to 3.Ian

Yes exactly so I made the limit switch m119 and for the end of the line m 591 d is the distributor number

and the film works perfectly instead of the switch does not work now I have replaced it and put it on two WiFi switch Z2config (22).g -

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

@droftarts said in DUEX 5 V0.8 TO DUEX 5 V0.11:

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

M119

M119 does not show filament sensor status, only endstop status for axes (X, Y, Z).

Send

M591 D#where # is the extruder drive number, 0 to 3.Ian

Yes exactly so I made the limit switch m119 and for the end of the line m 591 d is the distributor number

and the film works perfectly instead of the switch does not work now I have replaced it and put it on two WiFi switch Z2config (22).g -

@droftarts if it is possible for you we can see the problem of the loss of pace because the rest everything works

for other small problems I look at myself I do not want to take advantage of your kindness we see the biggest problem of the loss of the Step of X and Y -

; Endstops M574 X0 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z2 S1 P"!zstop+!e1stop" ;Filament Sensing M591 P2 C"e0stop" S0 D0 M591 P2 C"duex.e2stop" S1 D2 M591 P2 C"duex.e3stop" S1 D3 M591 P2 C"duex.e4stop" S1 D4With this configuration, homez.g works? And the filament sensing works?

Ian

-

@droftarts said in DUEX 5 V0.8 TO DUEX 5 V0.11:

; Endstops M574 X0 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z2 S1 P"!zstop+!e1stop" ;Filament Sensing M591 P2 C"e0stop" S0 D0 M591 P2 C"duex.e2stop" S1 D2 M591 P2 C"duex.e3stop" S1 D3 M591 P2 C"duex.e4stop" S1 D4With this configuration, homez.g works? And the filament sensing works? YES

Ian

-

M566 X1000.00 Y1000.00

M201 X2000.00 Y2000.00

I tried to make a print with this configuration without extruding the pitch I don't lose it but if I increase it I lose it

DM860H V3.3 act英文 (1).pdf 17HS19-2004S1.pdfI made the print at 100 mm and the displacement 130 mm

-

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

@droftarts if it is possible for you we can see the problem of the loss of pace because the rest everything works

Okay, back to the original problem. DM860H driver is made by Leadshine. I expect you have a Chinese clone version. All documentation I have found, except for the one you posted, has a different timing specification for the DM860H drivers. eg:

http://www.jdsmotion.com/products1/dma860h.pdf

https://manuals.plus/microrostep/leadshine-microstep-dm860-user-s-manualI suggest trying the following timing:

M569 P7 S0 R1 T3:3:6:6 ; E4 X physical drive 7 goes forwards M569 P8 S1 R1 T3:3:6:6 ; E5 Y physical drive 8 goes forwardsStated timing is minimum length. Timings can be longer than stated in documentation, but not shorter. This will not affect the speed you can achieve with the axis.

But note that even the pdf you linked says that signal level must be >3.5V.

Ian

-

@droftarts said in DUEX 5 V0.8 TO DUEX 5 V0.11:

@paolozampini1973 said in DUEX 5 V0.8 TO DUEX 5 V0.11:

@droftarts if it is possible for you we can see the problem of the loss of pace because the rest everything works

Okay, back to the original problem. DM860H driver is made by Leadshine. I expect you have a Chinese clone version. All documentation I have found, except for the one you posted, has a different timing specification for the DM860H drivers. eg:

http://www.jdsmotion.com/products1/dma860h.pdf

https://manuals.plus/microrostep/leadshine-microstep-dm860-user-s-manualI suggest trying the following timing:

M569 P7 S0 R1 T3:3:6:6 ; E4 X physical drive 7 goes forwards M569 P8 S1 R1 T3:3:6:6 ; E5 Y physical drive 8 goes forwardsStated timing is minimum length. Timings can be longer than stated in documentation, but not shorter. This will not affect the speed you can achieve with the axis.

But note that even the pdf you linked says that signal level must be >3.5V.

Ian

Ok so I apply this configuration and do a test test without instructions