Delta - Nozzle crashing into bed

-

@malkem said in Delta - Nozzle crashing into bed:

@blt3dp

I dont get it. I put the G30 between G28 and G32, the result is the same. As soon as the printer starts to print it crashes into the bed, not by much but I can hear the knock.

Would it help to decrease the Z-value in G31 P50 X0 Y0 Z-0.07?The larger the Z Trigger Height value the closer the nozzle ends up to the bed when Z is set to 0.

So make the value smaller could help with your problem.

Frederick

-

@fcwilt

Tried it out to decrease Z to -2 (G31 P50 X0 Y0 Z-2).

My printer doesn't care anymore. He lower the nozzle always to the same height, what is likely Z0.

I remember increasing/decreasing the G31 Z value helped me in version 2.05.Any other ideas?

Maybe the whole config.g will help?config.g

; Configuration file for Duet WiFi (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Mon Apr 11 2022 12:41:54 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"TLM" ; set printer name M665 L400.350:400.350:400.350 R172.703 H511.873 B155.0 X-0.022 Y-0.040 Z0.000 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E815.00 ; set steps per mm M566 X540.00 Y540.00 Z540.00 E240.00 ; set maximum instantaneous speed changes (mm/min) M203 X24000.00 Y24000.00 Z24000.00 E6000.00 ; set maximum speeds (mm/min) M201 X7500.00 Y7500.00 Z7500.00 E3000.00 ; set accelerations (mm/s^2) M906 X1600 Y1600 Z1600 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop ; Z-Probe M558 P8 R0.4 C"zprobe.in+zprobe.mod" H18 F1200 T6000 ; set Z probe type to effector and the dive height + speeds G31 P50 X0 Y0 Z-2 ; set Z probe trigger value, offset and trigger height M557 R130 S10 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M307 H0 R1.501 K0.636:0.000 D1.85 E1.35 S1.00 B0 ; PID parameter M140 H0 ; map heated bed to heater 0 M143 H0 S100 ; set temperature limit for heater 0 to 100C M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M307 H1 R2.755 K0.408:0.372 D5.79 E1.35 S1.00 B0 V24.0 ; PID parameter M143 H1 S260 ; set temperature limit for heater 1 to 260C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T125 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan1" Q500 ; create fan 2 on pin fan1 and set its frequency M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M501 ; Load saved parameters from non-volatile memoryconfig-override.g

; config-override.g file generated in response to M500 at 2022-04-12 20:28 ; This is a system-generated file - do not edit ; Delta parameters M665 L400.350 R172.703 H511.873 B155.0 X-0.022 Y-0.040 Z0.000 M666 X-0.599 Y-0.539 Z1.138 A0.04 B0.33 ; Heater model parameters -

You don't need to run a print to verify that things are OK.

Move the probe to the center of the bed. Execute G30. When done it should end up at appx Z=16.

Then jog down until the nozzle is just touching the bed. Check the Z position in the DWC. It should be close to 0 if all is well.

Frederick

-

Have you actually tried to measure your probe trigger height yet?

Also, just in case, can you send M122 and M98 P"config.g" and post the results?

-

@phaedrux

Hi and thanks for the reply!Here the results

M122

=== Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.0 (2022-03-15 18:58:31) running on Duet WiFi 1.02 or later Board ID: 08DGM-956GU-DJMSN-6JKD2-3SN6T-TVNRD Used output buffers: 3 of 24 (13 max) === RTOS === Static ram: 23868 Dynamic ram: 73840 of which 176 recycled Never used RAM 14196, free system stack 184 words Tasks: NETWORK(ready,13.0%,232) HEAT(notifyWait,0.0%,332) Move(notifyWait,0.0%,364) MAIN(running,85.7%,440) IDLE(ready,1.3%,30), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:01:23 ago, cause: power up Last software reset at 2022-04-14 23:32, reason: User, GCodes spinning, available RAM 14296, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Step timer max interval 0 MCU temperature: min 19.8, current 25.1, max 25.3 Supply voltage: min 24.2, current 24.2, max 24.5, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min n/a Driver 1: standstill, SG min n/a Driver 2: standstill, SG min n/a Driver 3: standstill, SG min n/a Driver 4: standstill, SG min n/a Driver 5: Driver 6: Driver 7: Driver 8: Driver 9: Driver 10: Driver 11: Date/time: 2022-04-15 11:46:34 Cache data hit count 2901757074 Slowest loop: 15.73ms; fastest: 0.19ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 1.2ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Network === Slowest loop: 161.06ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.26 WiFi MAC address 5c:cf:7f:76:68:64 WiFi Vcc 3.36, reset reason Turned on by main processor WiFi flash size 4194304, free heap 24408 WiFi IP address 192.168.178.33 WiFi signal strength -47dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 4 0 0 0 0 0 0 0M98 P"config.g"

HTTP is enabled on port 80 FTP is disabled TELNET is disabled Error: bad grid definition: Too many grid points; suggest increase spacing to 13.0mm Error: Pin 'fan1' is not free Error: Fan number 2 not found@phaedrux said in Delta - Nozzle crashing into bed:

Have you actually tried to measure your probe trigger height yet?

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Z_probe_testing#calibrate-the-z-probe-trigger-heightI've done this in the past but I will give it another try.

I haven't change any hardware components. -

Just measured the Z trigger height. It is -0.15

I've set the Z value to -2 so the nozzle should be far above the bed, am I right? -

@malkem said in Delta - Nozzle crashing into bed:

I've set the Z value to -2 so the nozzle should be far above the bed, am I right?

Yes. -2mm is pretty extreme. That would make it think that the nozzle is 2mm below the bed surface when the probe triggers.

So tell me this, set your G31 Z trigger height correctly to -0.15 and then if you do a G28 to home the towers and then a G30 to probe the bed to set Z0, if you then send G1 Z0 does the nozzle end up just touching the bed?

-

@phaedrux

Good morning phaedruxI just did how you said and the nozzle was not crashing into the bed.

The space between nozzle and bed was just enough to slide in the sheet of paper I used to determine the Z trigger height.

I've send G32 after G30 and went again to Z0 and nothing has changed, it was enough space to slide in the sheet of paper.

This part seems working fine.So what the hell is the problem of my printer?

I'm close to toss him out the window

-

I'm running out of ideas.

Should I downgrade? Is it even possible?

In my old config.g (v2.05) I've used P1 instead of P8 "M558 P1 H18 F240 R0.4 T4000"

Could it change anything?I took a look into the gcode file, there is also nothing suspicious in my opinion.

; generated by PrusaSlicer 2.4.1+win64 on 2022-04-16 at 18:16:02 UTC ; ; external perimeters extrusion width = 0.50mm ; perimeters extrusion width = 0.50mm ; infill extrusion width = 0.46mm ; solid infill extrusion width = 0.45mm ; top infill extrusion width = 0.40mm ; support material extrusion width = 0.35mm ; first layer extrusion width = 0.70mm M107 M190 S60 ; set bed temperature and wait ;TYPE:Custom ;M558 P1 H8.5 F240 R0.4 T4000 M558 P8 R0.4 C"zprobe.in+zprobe.mod" H3 F240 T6000 M109 S120 G28 G1 X0 Y0 Z8.5 F6000 G30 G32 ; auto calibration G29 S1 ; heightmap.csv G1 X0 Y0 Z100; lift nozzle M104 S210 M109 S210 G1 X0 Y0 Z10; lower nozzle G21 ; set units to millimeters G90 ; use absolute coordinates M82 ; use absolute distances for extrusion G92 E0 ;M572 D0 S0.05; linear advanced PLA-NX2 M107 ;LAYER_CHANGE ;Z:0.35 ;HEIGHT:0.35 G1 Z.35 F27000 G1 E-2.8 F2400 G92 E0 G1 Z.55 F27000 G1 X0 Y14.575 G1 Z.35 G1 E2.8 F2400 ;TYPE:Skirt/Brim ;WIDTH:0.7 G1 X-43.737 Y14.575 E6.49863 G1 X-44.622 Y14.439 E6.57429 G1 X-45.393 Y14.072 E6.64657 G1 X-46.033 Y13.478 E6.72039 G1 X-46.457 Y12.732 E6.79294 G1 X-46.657 Y11.769 E6.87613 G1 X-46.546 Y10.734 E6.96417 G1 X-46.132 Y9.713 E7.05727 G1 X-45.438 Y8.762 E7.15689 G1 X-22.591 Y-14.091 E9.88954 G1 X-21 Y-14.75 E10.03515 G1 X21 Y-14.75 E13.58686 G1 X22.591 Y-14.091 E13.73247 G1 X45.633 Y8.986 E16.4902 G1 X46.078 Y9.619 E16.5556 G1 X46.402 Y10.284 E16.6182 G1 X46.598 Y10.965 E16.67807 G1 X46.661 Y11.635 E16.73506 G1 X46.584 Y12.315 E16.79292 G1 X46.377 Y12.92 E16.84695 G1 X46.047 Y13.461 E16.90053 G1 X45.613 Y13.908 E16.95323 G1 X44.75 Y14.397 E17.03707 G1 X43.737 Y14.575 E17.12405 G1 X.06 Y14.575 E20.81758 G1 X.06 Y13.95 F27000 G1 F2400 G1 X-43.722 Y13.95 E24.52001 G1 X-44.426 Y13.846 E24.58014 G1 X-45.043 Y13.554 E24.63786 G1 X-45.533 Y13.103 E24.69422 G1 X-45.878 Y12.498 E24.7531 G1 X-46.035 Y11.694 E24.82235 G1 X-45.925 Y10.831 E24.89594 G1 X-45.559 Y9.97 E24.97506 G1 X-44.963 Y9.169 E25.0595 G1 X-22.149 Y-13.649 E27.78808 G1 X-21 Y-14.125 E27.89325 G1 X21 Y-14.125 E31.44496 G1 X22.149 Y-13.649 E31.55013 G1 X45.101 Y9.324 E34.29624 G1 X45.779 Y10.41 E34.40454 G1 X45.961 Y10.973 E34.45455 G1 X46.034 Y11.532 E34.50226 G1 X45.996 Y12.068 E34.54771 G1 X45.849 Y12.571 E34.592 G1 X45.597 Y13.018 E34.63538 G1 X45.24 Y13.405 E34.67995 G1 X44.547 Y13.806 E34.74759 G1 X43.725 Y13.95 E34.81815 G1 X.12 Y13.95 E38.50562 G1 E35.70562 G92 E0 G1 Z.55 F27000 G1 X-20.161 Y-1.329 G1 Z.35 G1 E2.8 F2400 ;TYPE:Perimeter G1 X-20.429 Y-.989 E2.83663 G1 X-20.751 Y-.714 E2.87243 G1 X-21.128 Y-.502 E2.90899 G1 X-21.53 Y-.372 E2.94472 G1 X-21.957 Y-.321 E2.98107 G1 X-22.364 Y-.351 E3.01556 G1 X-22.781 Y-.465 E3.05212 G1 X-23.169 Y-.66 E3.08883 G1 X-23.502 Y-.92 E3.12457 G1 X-23.784 Y-1.248 E3.16116 G1 X-23.991 Y-1.614 E3.19668 G1 X-24.124 Y-2.012 E3.23219 G1 X-24.179 Y-2.443 E3.26895 G1 X-24.147 Y-2.876 E3.3057 G1 X-24.034 Y-3.283 E3.34141 G1 X-23.84 Y-3.669 E3.37791 G1 X-23.581 Y-4 E3.41346 G1 X-23.264 Y-4.276 E3.44898 G1 X-22.888 Y-4.49 E3.48555 G1 X-22.488 Y-4.624 E3.52129 G1 X-22.059 Y-4.679 E3.55783 G1 X-21.638 Y-4.649 E3.59351 G1 X-21.219 Y-4.535 E3.63025 G1 X-20.831 Y-4.339 E3.66702 G1 X-20.498 Y-4.08 E3.70269 G1 X-20.217 Y-3.753 E3.73914 G1 X-20.009 Y-3.387 E3.77478 G1 X-19.875 Y-2.986 E3.81052 G1 X-19.821 Y-2.544 E3.84817 G1 X-19.854 Y-2.122 E3.88399 G1 X-19.966 Y-1.716 E3.91955 G1 X-20.134 Y-1.383 E3.95117 G1 X-20.691 Y-1.666 F27000 ;TYPE:External perimeter G1 F2400 G1 X-20.882 Y-1.424 E3.97729 G1 X-21.11 Y-1.229 E4.00268 G1 X-21.38 Y-1.077 E4.02882 G1 X-21.665 Y-.985 E4.05414 G1 X-21.971 Y-.949 E4.0802 G1 X-22.258 Y-.97 E4.10451 G1 X-22.556 Y-1.051 E4.13066 G1 X-22.833 Y-1.191 E4.15685 G1 X-23.069 Y-1.375 E4.18218 G1 X-23.271 Y-1.609 E4.20835 G1 X-23.418 Y-1.869 E4.23357 G1 X-23.512 Y-2.152 E4.25879 G1 X-23.551 Y-2.459 E4.28502 G1 X-23.528 Y-2.769 E4.31124 G1 X-23.448 Y-3.057 E4.33655 G1 X-23.309 Y-3.333 E4.36265 G1 X-23.126 Y-3.568 E4.3879 G1 X-22.9 Y-3.764 E4.41312 G1 X-22.632 Y-3.917 E4.43929 G1 X-22.348 Y-4.012 E4.46461 G1 X-22.041 Y-4.051 E4.49075 G1 X-21.743 Y-4.03 E4.51602 G1 X-21.444 Y-3.949 E4.54224 G1 X-21.167 Y-3.809 E4.56848 G1 X-20.931 Y-3.625 E4.59375 G1 X-20.73 Y-3.392 E4.61981 G1 X-20.583 Y-3.131 E4.64514 G1 X-20.488 Y-2.847 E4.67046 G1 X-20.449 Y-2.53 E4.69748 G1 X-20.472 Y-2.231 E4.72288 G1 X-20.552 Y-1.943 E4.74814 G1 X-20.664 Y-1.72 E4.76925 G1 X-20.549 Y-1.392 F27000 G1 E1.96925 F2400 G92 E0 -

Why did you change to probe type 8?

I would think the strain gauge would output an analog signal.

Frederick

-

@fcwilt

I changed it back to P1, it didn't help. Got the same results.

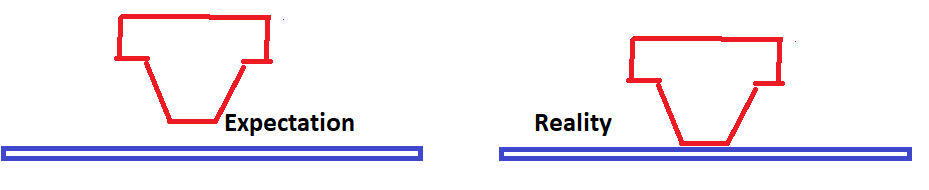

If I do it manually G28 -> G30 -> G32 and move the nozzle to Z0, there is a gap between bed and nozzle, just how we would expect.If I upload a gcode file and start to print, the DWC shows that the nozzle is moving to the first layer height to Z.35. But the nozzle is actually flat on the bed.

-

Well in the print file you have G28 then G30 then G32 then G29.

Remember that G29 is going to change the Z position based on the X/Y position.

Also for the height map to work correctly you need to set the Z=0 Datum before creating the height map and before loading the height map. Moreover the X/Y position used for setting the Z=0 Datum must always be the same. I use the center of the bed which for me is at X=0 Y=0.

I don't have a delta so I am not sure what G32 does, exactly, but I think you should still have a G30 at your reference point before you do the G29.

And did you set the Z=-0 Datum before creating the height map?

Frederick

-

@fcwilt

Hi and thanks for your time helping me out here

heightmap and G29 was never a problem before. I've also tried without G29.

I downgraded to version 2.05 and my printer works again.I dont know if this is a bug or just me doing something wrong.

If you guys want me to try something out, I will do it. But for now I'll stay on version 2.05.