HotBed Heating Too Slow?

-

I thought so too, and I could get close, but never quite reach it.

-

@phaedrux I've never meant a proportional integral I didn't find derivative.

-

6/23/2022, 3:01:49 PM Warning: Auto tune of heater 0 failed due to bad curve fit (R=0.129 K=2.291:0.000 D=2.92)

-

@jay_s_uk well, the tuning failed three times. so I've gone back and changed the profile to PID for the bed, and now we're going to see if that will help it pass DWC's tuning procedures.

-

What command did you use to start the tuning?

Are you starting from ambient temp?

What does your heater temp graph look like during the process?

Do you have the correct thermistor values set for your sensor? -

@phaedrux thanks for asking, I've edited the config.g maybe a dozen times today.

- M303 H0 S60. That test failed. I reduced the 60 to 40. That test failed. Then I reduced it to 16. I don't remember the message, but it sounded like something had gone very wrong.

- Room temp's in the seventies.

- The graph shows a line progressing to the right.

- I didn't, but I continued to edit the config.g file to change that until I got something like an NTC 3950, which is as vanilla as the choices are, I think.

Anyways, when the last test crashed, I decided to work on changing the motors from being X and Y reversed to X and Y forwards, and Z reversed.

Which lead to:

I've got movement on all 3 axis. For X, the print heads goes up, then down about 2-3- inches when I home it. After that, I can move it to the right incrementally until it gets to the far right side of the printer. Getting it to come back is hit and miss, but mostly misses.

For Y, the bed goes towards the front when you click on Y-50 and towards the back when you click on Y+50. So I'm guessing I should reverse Y.

The printer has no idea where home is (far left is 0 for X, far back is 0 for Y, and 2.5mm above the bed is 0 for Z (because the BLTouch is working properly, but I haven't tweaked it's elevation yet).

Mark

-

@mac I forgot two things.

-

I changed the voltage of all the motors to 600ma

-

I changed the steps to 32.

-

-

@rushmere3d see the post above this one, there’s good news.

-

System marked this topic as a question

-

https://youtube.com/shorts/HVZQz00e_HE?feature=share

This 40 second video on YouTube shows my printer X-homing, Y-homing, and Z-homing in that order.

-

@mac definite progress with that video! A couple of things…

- Is the back right corner of the bed the ‘origin’, ie X0 Y0, for you? This is okay (prints won’t be mirrored, but will be rotated 180 degrees), but usually the origin is when the nozzle is over front left. Or you can get fancy and set the centre as the origin.

- Most printing starts in the middle of the bed, so it’s usually best to probe for Z in the middle of the bed, too.

- Motor noise. The stepper drivers on the Mini 5+ support two stepping modes; stealthchop and spreadcycle. In stealthchop, the motors will be quieter, but have less torque, so there is a slightly higher chance of missed steps (usually only when moving fast and the nozzle hits something). Spreadcycle has more torque, but is noisier. There are various things you can do with these modes, but for now, trying sending in the console:

M569 P0.0 S0 D3 M569 P0.1 S0 D3 M569 P0.2 S1 D3 M569 P0.3 S1 D3Stealthchop is supposed to be the default for the drivers on the Mini 5+ in RRF 3.4, so this may not make a difference.

Ian

-

@droftarts the home point for this Xvico was the FRONT, LEFT, Corner.

Did you watch the 40 second video (see link above?)?

When one Home's the X-axis, is it supposed to go up a few inches, then come back down a few inches?

Why is homing the x-axis telling the z-axis to go up and then down?

Mac / Mark / Corlissmedia (2.0)

-

@droftarts Okay, in the Console, I sent all 4 of those commands. The printer responded by moving up and down, up and down, up and down, and then it tried to land on the bed, but the BLTouch told it to get off of me (I guess the BLTouch has been reading the New York Times over the last hour or so), so the print-head continued to climb until I turned the printer off to keep it from pounding against the top rail.

Mark

-

@droftarts M569 P0.2 S0 D3 silenced the noisy fan!!!!!

FINALLY, some progress!

-

@mac Yes, of course I watched the video! That's what I was commenting on.

the home point for this Xvico was the FRONT, LEFT, Corner

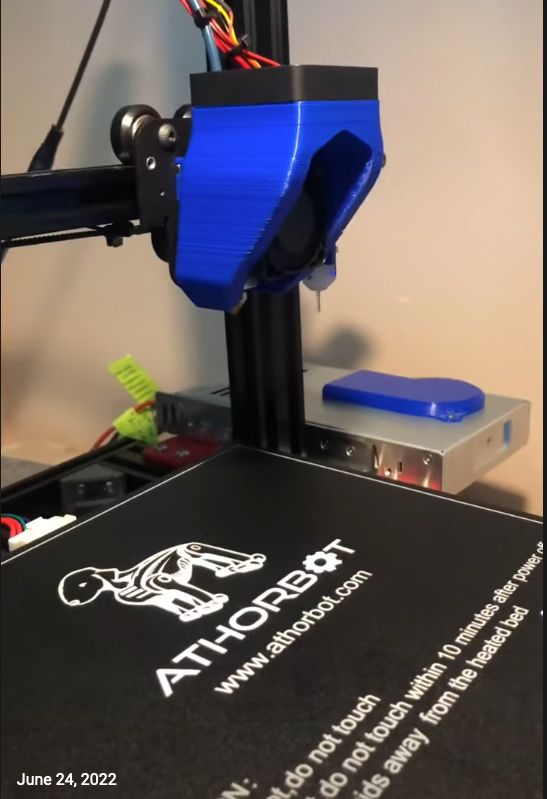

Sorry, but I'd say the nozzle in the image below is over the back right corner, viewed from the front of the machine (ie reading the text on the bed the correct way up, left to right). If you've set the endstops up as maximum endstops (ie bed maximum position is set when homed, like X200 Y200), then fine, but if they're set up as minimum endstops, the machine coordinates are rotated 180 degrees. Just for clarity: the X axis is (usually) the one that has the nozzle on it (goes left/right), the Y axis is the bed (goes forward/backward).

I copied the M569 commands from the config.g you posted a few days ago. I probably should have said to check the 'S' parameter in them (that's the axis direction)! It's the D3 that silences the motors. It should not have made the motors move, or done anything to the fan. I thought the squealing was motor coil whine, not the fan! Because it stopped when you moved an axis. If it helps, add it to the M569 commands in config.g. Maybe post your current config.g in this thread, too.

Why is homing the x-axis telling the z-axis to go up and then down?

Because homex.g tells it to. Usually it's best to lift the nozzle before homing, just in case it has stopped on the bed, or stopped during printing, so it stops the nozzle being dragged along the bed. Lifting it 5mm is normal, and it usually drops it again after the X (and Y does the same thing) has been homed.

Ian