PID tuning Thick bed

-

Running into an issue with Z banding that I believe is from Heating of my 1/2" Thick MIC6 Alum Bed with 120v AC heater.

banding still persists after I have run PID autotuning on it. but it does take a long time to heat up and cool down.

What parameters should I use to PID tune this bed?

I dont typically run it hotter than 80 degreesM308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M140 H0 ; Map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 R0.668 K0.284:0.000 D5.21 E1.35 S1.00 B0 ; PID BED Tuning

-

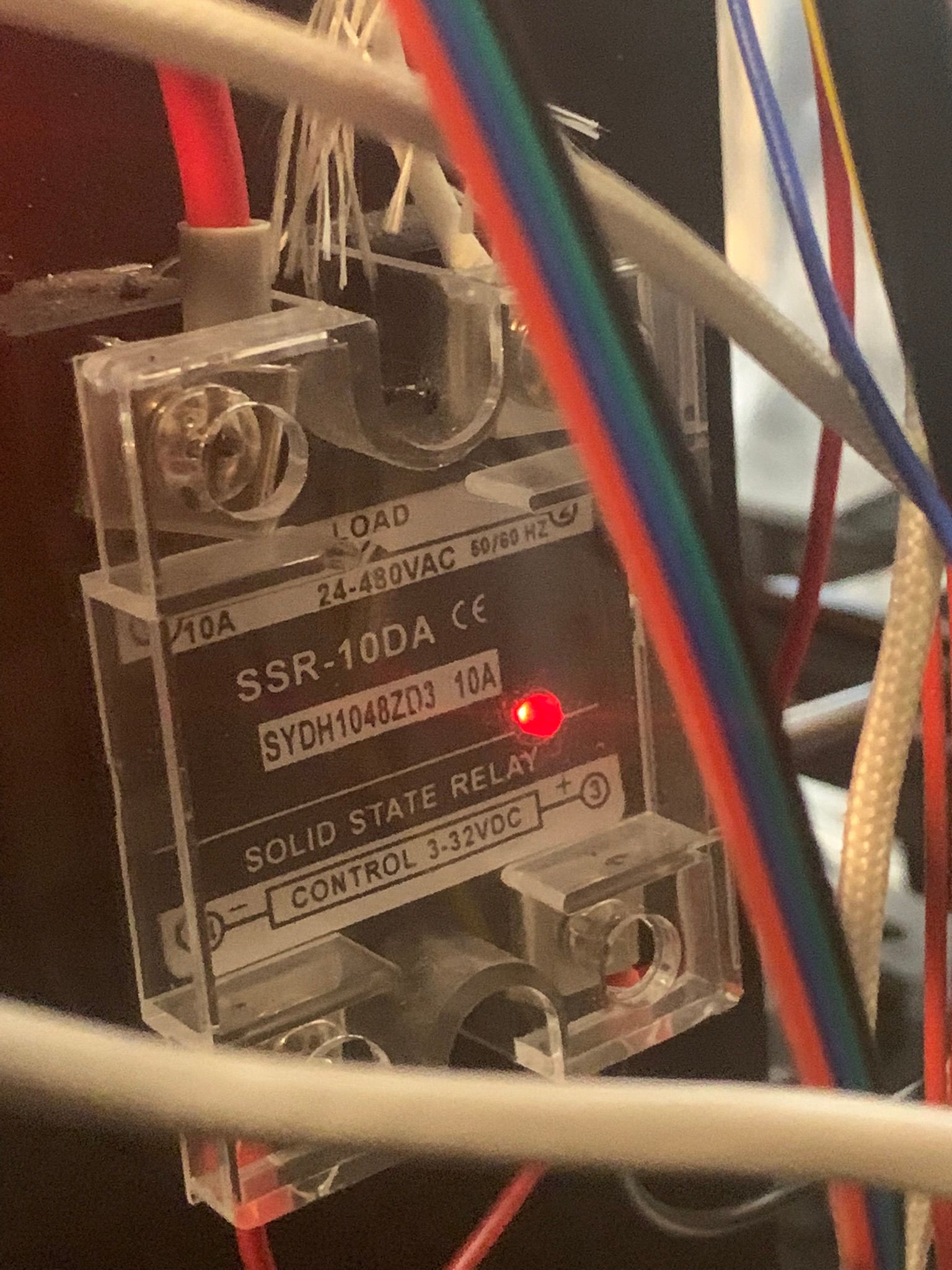

@adamfilip Could the reason be the B0 Parameter should I use B1 instead? running on a Solid state Relay to control the AC power

-

@adamfilip I am using an old cheap chinese SSR SYDH1048ZD3 SSR-10DA perhaps its not fully compatible?

.

-

@adamfilip I'd bet on the banding being due to Z motion, given that it looks pretty periodical in Z. Bent lead screw perhaps and otherwise unconstrained build plate?

-

@spoonunit my machine is like Voron 2.4 with Belted Z

Bed is fixed, constrained to frame -

-

@adamfilip There's still Z motion, but it's the head instead of the bed. That said, looks like you have linear rails for the Z motion, which ought to be great. I'd still look for Z motion first to be sure. Can you visually just watch the head as you increase and decrease Z and say there's not a jot of motion?

-

@spoonunit Also, your SSR is typically controlling heat to the bed, not the hot end. Or is that machine different in that respect too?

-

@spoonunit yes I am using SSR to heat bed with 120v ac power

-

@spoonunit my machine uses exoslides instead of linear rail. not sure what you mean by jot of motion. things are well constrained if you are referring to backlast or slack in the motion.

-

@adamfilip if you mean the bed is bowing with "heater on" pulses you can fix a cheap indicator to the print head or there abouts and see if that's really what's happening. I have a bed slinger with glass bed/ac heater and it bows up and down a tone even if the PID is real tight. You may not be able to get the PID good enough because of the slow thermal response of all that mass. I sometimes use a simple ac rheostat (fan motor controller) to manually set the ac voltage/bed temp which eliminates any heater cycling but its finicky and needs to be improved upon

-

Do a test print with the bed heater off and see if the banding disappears.