As I logged on to the forum this morning I had a realization or perhaps I was just having a "moment". For the majority of us this is a hobby. A passionate one at that. We lay in bed at night dreaming of that perfect print or a new design. Seeing all the challenges people face and then overcome I couldn't help but feel appreciation for the tireless efforts of David, Tony, the moderators and all the contributors driven by this passion. Thank you.

Personally I am challenged when it comes to the electronics/computer side of the machine. Hell, I didn't even own a computer until I was in my mid 20's yet because of the efforts of this organization I have been able to create some awesome stuff and plan to make more. Keep it up guys

Best posts made by 3DPMicro

-

Positive Rantposted in General Discussion

-

Duet controlled micro millposted in My Duet controlled machine

I've been working on this one for a couple months. Using Misumi LX20 actuators with 1mm lead ball screws driven by 1 amp, 1.8 nema 14's on x and y (10 kg of force) and a .9 nema 17 on the Z using 75 mm square, steel bar as the foundation. Tool is driven by a 150K RPM Nakanishi air spindle. The purpose of the build is high accuracy micro machining. I have just ran the first test part, a 9mm diameter sprocket, and it turned out phenomenal (inspecting it with a digital microscope). I plan to try some 3D contouring next and then find the limits in part sized using .5 and .25 mm end mills I have.

-

RE: Duet controlled micro millposted in My Duet controlled machine

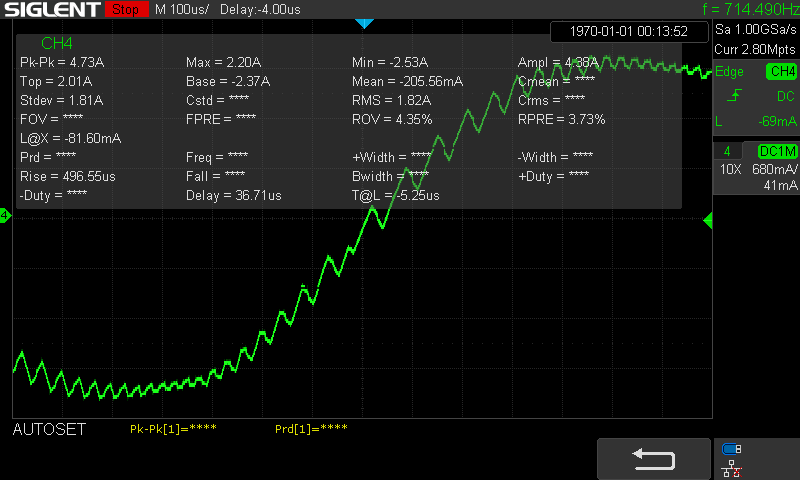

I was able to get the motors to run over 1200 RPM (1200 mm/m travel speed) but while using my test program they stuttered when interpolating corners below a certain radius (G2/G3) with 16x ms, interpolated. Still almost silent and smooth at 8x Ms w/o interpolation. I went all over the place with Accel, and jerk with no apparent effect on the stuttering until down, around 600 mm/m. This 2.3 mm thick part took 14 minutes using a .81 mm end mill including interpolating the 6, 1 mm mounting holes. .1 mm axial DOC and 400 mm/m feed.

The demensions I can measure easily came out within .02 mmp.s. for the record i was not actually using the bathroom when I took the picture

-

RE: Duet controlled micro millposted in My Duet controlled machine

My little micro Mill has been working great. No hicups other than the PanelDue touch screen not always working right (too lazy to investigate). I make high precision machined parts at my job using $500k equipment and it still amazes me how accurate and repeatable this $800 machine is. Latest project was a gift I made for my parents 50th wedding anniversary. Using a 20 deg engraving bit with a .1mm tip the machine was consistently able to ablate the thin aluminum film from the backside of the mirror with only minor signs of etching the glass in a few places. This was after surfacing the spoil plate and verifying flatness within .005 mm. This tells me at least the Z is hitting the theoretical .003 mm resolution and doing it pretty darn consistently.

-

RE: Duet controlled micro millposted in My Duet controlled machine

The Duet 2, with regularily updated FW has been flawless through many projects over the last few years guiding this little mill. I have the same confidence in it as any of the professional grade machines I run at work.

I thought if it could be tripped up the g code for 3d maching the .5mm radii on this part would do it. Resolving moves as small as 100nm for the inside corners there was no indication of lost steps or rounding errors (the floating point goes that low?) over the 8 parts that were made. Pretty cool

https://youtu.be/27_E8RawCyQ

There were 0 hiccups and 0 errors but underruns showed 0,0,4. What does that mean? -

RE: Ground loops don't only affect 3D printersposted in Off Topic

Tail dragers can be equally frustrating because of a ground loop

-

RE: single block and feed holdposted in CNC

@miss-rebekah I'm a machinist too (30 years in aerospace) . I think it's important to realize the value in the Duet. I dont think it was ever intended to be a full feature cnc controller (although it is quite capable) rather the focus is on 3d printing. For less than $150 it is extremely powerful but it does lack a a tad in the cnc department but continualy improved. I assume if you are going single block you are not doing the programming were here you will program so you already know what the machine is supposed to do next. Although there is no feed hold (before the buffer runs out) that I am aware of you can set up an emergency stop button that will keep you from tearing anything up. If you want your router to act like your machine at work I would suggest looking at Acorn or Oak but be prepared to pay a lot more for those additional features you mentioned. I say give it a try and I'll think those few things will become a non issue. Duet and RRF is very user friendly once you get past the learning curve and it's all g code so I think you'll feel very comfortable with it.

-

Sanity Check Plz!!! Omron Inductive switch for XYZ endstopsposted in Duet Hardware and wiring

This is for a mill so no Z probing. I can get 3 of these dirt cheap https://www.ia.omron.com/product/item/1017/

and would like to use them on a new mill build. Here's my board info...

I see info here https://duet3d.dozuki.com/Wiki/Connecting_a_Z_probe#Section_Mode_Num_5

on how to connect as a Z probe but how do I hook them up for XYZ endstops?

Thanks -

RE: DWC won't open. What am I missing? Solvedposted in General Discussion

Just upload the DuetWebControl.zip file through the Settings General tab of DWC. It will be unzipped and the files will be put in the correct folders automatically.

I cant get the DWC to open

Latest posts made by 3DPMicro

-

RE: Microstepping and other ponderingsposted in Tuning and tweaking

@dc42 thanks for the response. It seems like I will be in pretty good shape then as I'll be using 1/4 -1/2 the mechanical ratio of a typical belt driven 3d printer at 16x ms (im using 10 or 20mm lead screws, not belts) Although either 4 or 8x ms would be apples to apples as opposed to the 2x in the example above.

TLDR

Have you been able to determine (or a gut feeling) at what point resolution effects print quality? On a typical 20t belt drive Cartesian printer at 16x ms the ms resolution is .0125mm which seems significantly finer than would be required from a positioning standpoint -

Microstepping and other ponderingsposted in Tuning and tweaking

6HC V1.02

The top image is 2x ms w/interpolation, 40 steps/mm. The bottom image is 16x I1, 320 steps. There may be subtle differences, but the motor sounds the same for each all the way up to 2400rpm.

What's the advantage/disadvantage of running either ms'ing? -

RE: Limit Switch selectionposted in General Discussion

@NANDHAKUMAR10 I like these

https://www.ia.omron.com/product/item/1017/

and have used then on several machines. You can get them with different sensor styles. They are very expensive new, but can be purchased from eBay, new and used for next to nothing. -

RE: Extruder best at extruding?posted in 3D Printing General Chat

@o_lampe ahh yes. I remember the screw extruder from way back on the reprap forums when everyone was trying to figure stuff out. Do you remember where that thread was? Couldn't find it in a search

Edit- I see there's a rolling screw extruder out there. The one I was thinking about on the reprap forums actually drove the screws which did create a twisting force on the filament but this is coming from a 10 + yo memory so im really not sure.

Don't know if you've seen this guys videos. He's moved on to other things but he has some pretty good technical content from a couple years ago

https://youtube.com/@miragec?si=PSx9g8ZJtHsAzLb3 -

Extruder best at extruding?posted in 3D Printing General Chat

I havent been keeping up over the last several years so what direct drive extrusion design, extruder and hot end, is regarded as producing the most accurate extrusion with the least amount of artifacts?

Looking around it appears HeVort from MirageC (I think and based on another design?), Prusa planetary, Bambu Labs or Bondtech have all created designs that fix issues. Back in the mid to late 20 teens E3d was the bomb. I'm sure they have a formitable offering. Any indication of one that stands above the rest?

Opinions welcome. -

High quality power supplies for cheap USposted in Off Topic

This is not an advertisment and I won't name any specific sellers on US ebay but if you search for tdk lambda and flex power PSU's there's some great deals. I have been using an $800 Flex for the last couple weeks that I bought for $25. Has 5v 10a, 12v 5a, 2x24v 5a and 48v 8.5a. Purchased a tdk lambda with similar specs also for $45. It's surplus from decomisioned equipment but is in great shape and the seller has dozens of them. Don't buy potentially dangerous junk for the same price when you can get these.

-

RE: Error - Incompatible software versionposted in General Discussion

To anyone in the future that is creating files, like hand typed gcode in "text editor" on their Pi and can not figure out why DWC "upload and start" won't recognize the file its because the file name needs to end with .txt (or .gcode, etc). The Pi text editor doesn't have a file extension by default. A bit of a doh moment for me when it slapped me in the face

-

RE: Error - Incompatible software versionposted in General Discussion

@droftarts

@jay_s_uk

That did it. Thanks for the help gents. If I would have read the 6hc/sbc documentation carefully enough I should have picked that up.

Not a necessity but it would still be nice to know why a text file writen on the Pi isn't recognized by DWC upload and start. -

RE: Error - Incompatible software versionposted in General Discussion

@jay_s_uk

Duet 3 MB6HC MB6HC 3.5.3

Duet Software Framework DSF 3.5.4

Duet Web Control DWC 3.5.4