difference between 1LC and BTT canbus tool head Ebb 36/42

-

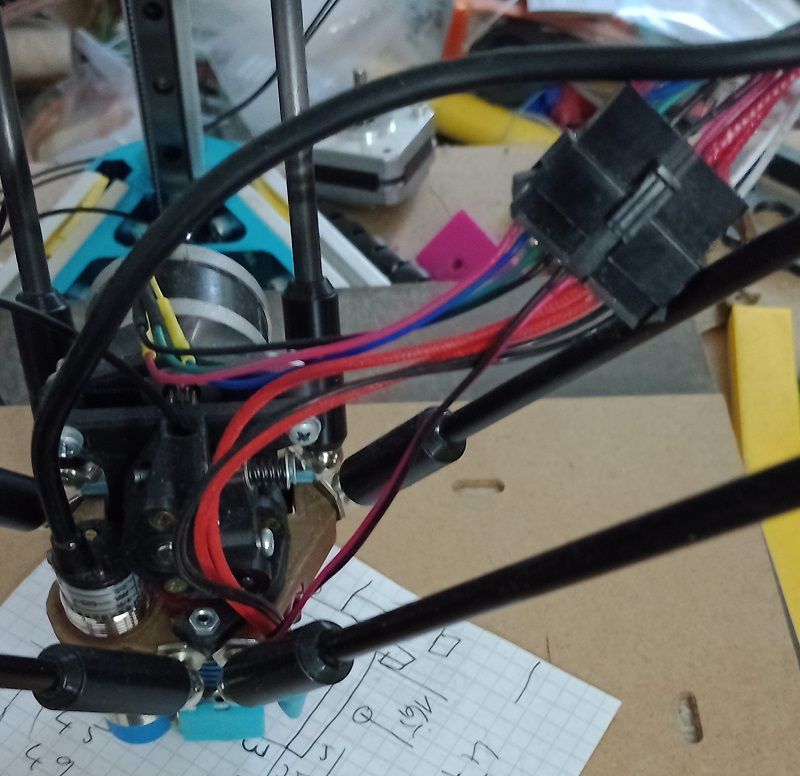

I am trying to understand why the 1LC has so many more components then the Ebb. I want to figure out how to make the 1LC smaller to fit the mini extruders using nema 14 round steppers. But first I need to understand what the 1LC has that Ebb does not have

-

@cncmachineguy the biggest difference is that the Duet tool board uses CAN-FD protocol to get sufficient bandwidth for worst-case conditions, where as the BTT board does not.

Another difference is that the Duet tool board includes EMI suppression components that the BTT board does not. It would likely be impossible to achieve CE certification (maybe also FCC certification) using the BTT board without enclosing the whole printer in a metal box or similar EMO shield.

-

@dc42 Thanks dc, that makes perfect sense. So really it is another case of theirs is really inferior as normal. So no way to make it smaller either.

I assume there are no unneeded functions on the 1LC.Also to be clear I am the same person from openPNP that wants to modify the board.

I haven't given up that yet. -

@cncmachineguy the 1LC has quite a lot of I/O and it may well be that your application doesn't need all of it. The connectors take up a lot of space, so removing unused I/O would make the board smaller.

If the rated hot end current was reduced so as to support heaters no greater than 50W @ 24V then the VIN connector and the hot end connector could be smaller.

Removing the option to support 12V fans would allow one of the voltage regulators to be removed.

You could also remove the accelerometer if you don't need it.

Board space could be reduced by fitting components on both sides of the board, although this would increase manufacturing costs and it would likely be necessary to change from a 4 to 6 layer PCB.

We are aware of the trend towards smaller extruders and we have been looking at making a cut down tool board for them.

-

@dc42 The accel needs to stay IMHO. it is always needed for tuning.

I for 1 would be fine losing all the connectors for solder pads, but I have been soldering for many years.I would say the fans can be 24V only. after all if you need 12v fans run a 12v power supply LOL

I can't speak to the extruder power yet

-

@cncmachineguy said in difference between 1LC and BTT canbus tool head Ebb 36/42:

I for 1 would be fine losing all the connectors for solder pads, but I have been soldering for many years.

I'd put them all together on one remote connector and be able to change the effector quickly. (for different nozzle sizes or multicolor)