how to calibrate the axes

-

how to calibrate the axes?

is there a guide somewhere...I haven't found any yet? -

@axiom What do you mean by calibrate?

-

@rushmere3d

If I move the z-axis 100mm across the dashboard, it actually only travels 63mm...I'd like to adjust that -

@axiom The steps per mm an axis takes is a known value of the hardware you have. See this https://blog.prusa3d.com/calculator_3416/ and look at the stepper motors section.

-

@rushmere3d

Entschuldige, aber auch mit Hilfe von Google-Übersetzer verstehe ich das nicht. Wenn ich anstatt 100mm weg nur 63mm habe...was muss ich dann wo im code ändern? -

@rushmere3d Sorry, but even with the help of google translator I don't get it. If instead of 100mm I only have 63mm away... what do I have to change where in the code?

-

@axiom You have to change the Steps per mm or M92 in the config.g file. You need to work out the steps required from the hardware you have.

-

@axiom Whats the tooth count of your pulley's?

-

@rushmere3d said in how to calibrate the axes:

Whats the tooth count of your pulley's?

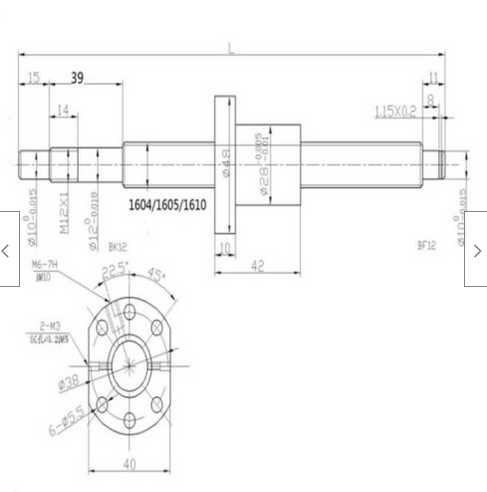

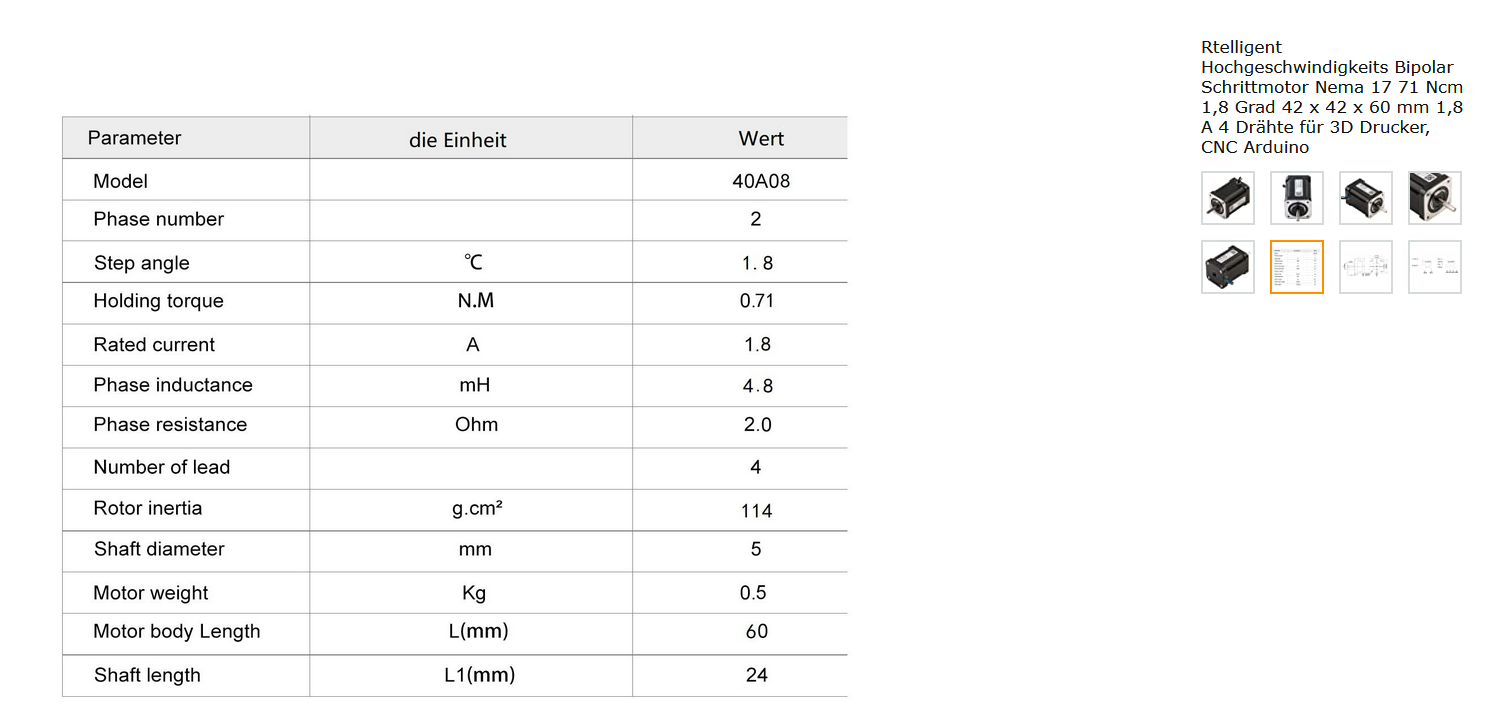

I have this information about the stepper motor.... does it do anything?

-

@axiom What printer? The pulley is the part the belt ride on. Post your config.g in the </>

-

@rushmere3d said in how to calibrate the axes:

What printer? The pulley is the part the belt ride on. Post your config.g in the

the printer is self-built... the Z-axis does not run on belts but on a spindle

Here is the code:; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm

M566 X900.00 Y900.00 Z120.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z30.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1680 Z2000 E1800:1800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout -

@axiom OK what are the spec of them?

-

-

@axiom Do you 1) have a picture of them 2) a link to where they were purchased? You could work out the step per mm from your movement test It would work out to be around 635 but it's best to do it with the manufactures specs. I can't understand that picture for the info I need.

-

@rushmere3d

https://www.ebay.de/itm/393158460107It ist the version1605 with a pitch of 5mm

-

@axiom The calulator suggests with a 5mm pitch that your steps per mm should be 640 so M92 Z640

-

@axiom The calculation goes like this. One revolution of a 1.8 degree stepper (the most common type) is 200 full steps. Assuming your stepper is directly connected to the screw, or you use 1:1 gearing, then we can say that one revolution of the screw is also 200 full steps. The next thing we need to know is how far a lead screw nut would travel if the screw rotated 1 revolution. This is given by the lead of the screw. If the screws are single start then the lead is the same as the pitch. If the screws are two start, then the lead is twice the pitch and if the screws are four start, then the lead is four times the pitch. As an example, let's assume the lead is 2mm. Then we know that in one revolution a nut will travel 2mm. So 200 full steps is 2mm therefore 1mm must be 100 full steps. The steps per mm are usually expressed as 16x micro-stepping so the number you need is 100 x 16 = 1600 steps per mm. If your motors are 0.9 degree, then one full revolution will be 400 full steps giving 200 full steps mm which would be 3200 @ 16X micro stepping.

Edit. So you just need to know the step angle of the motor you are using, and the lead of the screw. If the motors are not directly coupled, then you also need to take account of any gearing.

-

@deckingman

I haven't understood it yet, but maybe also because I can't concentrate so well anymore...it was a long day.But: Z 640 worked!!!! Thank you so much!! I'll have to take my time to look at the explanation again... how long are these dialogs stored in the forum?

cheers,

Don -

@axiom said in how to calibrate the axes:

@deckingman

I haven't understood it yet, but maybe also because I can't concentrate so well anymore...it was a long day.But: Z 640 worked!!!! Thank you so much!! I'll have to take my time to look at the explanation again... how long are these dialogs stored in the forum?

cheers,

DonThe posts stay pretty much forever.

Substituting your 5mm lead into what I said above, we get 200 full steps(one revolution of the motor) gives 5mm of linear movement. So 1mm is 200/5 = 40 full steps. Multiply that by 16x micro stepping and we get 640.