Adding a Z-hop to IDEX tool changing

-

Firmware version: RRF3.4.5

I'm trying to understand proper IDEX behavior with getting everything setup with the tool changing files, and one of the things I'm trying to accomplish is having a proper Z-hop movement added to the tool changing scripts. However I'm running into an interesting issue which I suspect cannot be fixed configuration side wise, and would need to be done slicer side

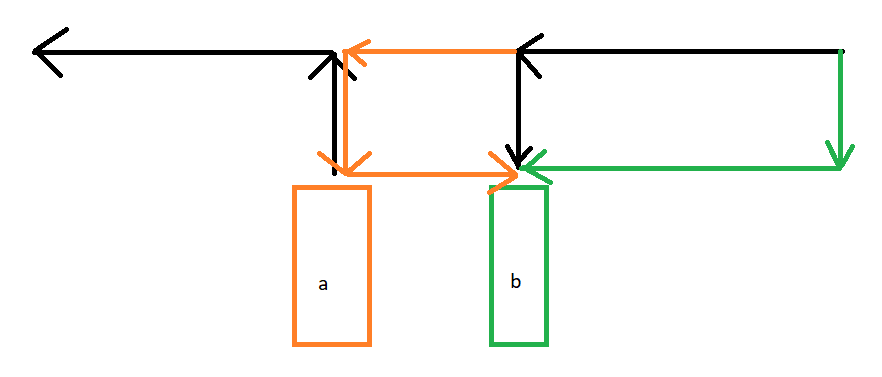

The idea is to have a Z-hop movement in the tool changing script, where the tool would move up, then away from the print, and on selecting the new tool it would move back down (the lines shown in the graphic below with the black lines). However

with the below tool changing scripts, it moves down, then to the next object (so the green pathway)I was able to make a script that first moves back to the XYZ coordinates of the previous selected tool, and then go to the new XYZ coordinates, but sadly that's also not always an ideal solution (orange pathway). The code for this is in the last bit of the commented out tpost0.g and tpost1.g (so the G1 R2 Z3 X0 Y0 followed by G1 R2 Z0. I have also tried it without the G1 R2 Z0, but in that case it behaves the same as with just the G1 R2 Z3 X0 Y0)

If anyone has any things to try out, I would love to hear them, otherwise it is most likely a slicer side solution that I'll have to dig in more

Here are the tool changing scripts:

Tfree0.g

; tfree0.g ; called when tool 0 is freed ; if job.file.fileName = null ; Check if printing a file G4 P1 ; If you're not printing, don't extrude else if heat.heaters[0].current < 160 ; check for temperature G4 P1 ; dont retract if heaters aren't at temperature yet else M83 ; relative extruder moves G1 E-5 F1200 ; retract 5mm M106 S0 ; disable fan G91 ; relative moves if {(move.axes[2].machinePosition) < (move.axes[2].max - 5)} ; check if there is >5mm space to raise head G1 Z+4.5 F3600 ; move Z up by 4.5mm elif {(move.axes[2].machinePosition) < (move.axes[2].max - 2)} ; if there is >2mm but <5mm G1 Z+0.5 F3000 ; raise by 1.5mm else ; if there isn't enough space, don't lift. G4 P20 ; wait 20ms G90 ; absolute XYZ moves if job.file.fileName = null ; Check if printing a file G4 P1 ; If you're not printing, don't extrude else if heat.heaters[0].current < 160 ; check for temperature G4 P1 ; dont retract if heaters aren't enabled yet else G1 E-5 F3600 ; retract 5mm G91 ; relative positioning G1 H1 Y{(move.axes[1].max+5)*-1} F6000 ; home Y axis G1 H2 Y2 F3000 ; go back a few mm G1 H1 Y{(move.axes[1].max+5)*-1} F600 ; move slowly to Y axis endstop once more (second pass) G4 P0 ; wait for movements to complete G90tfree1.g

; tfree1.g ; called when tool 1 is freed ; if job.file.fileName = null ; Check if printing a file G4 P1 ; If you're not printing, don't extrude else if heat.heaters[0].current < 160 ; check for temperature G4 P1 ; dont retract if heaters aren't at temperature yet else M83 ; relative extruder moves G1 E-5 F1200 ; retract 5mm M106 S0 ; disable fan G91 ; relative moves if {(move.axes[2].machinePosition) < (move.axes[2].max - 5)} ; check if there is >5mm space to raise head G1 Z+4.5 F3600 ; move Z up by 4.5mm elif {(move.axes[2].machinePosition) < (move.axes[2].max - 2)} ; if there is >2mm but <5mm G1 Z+0.5 F3000 ; raise by 1.5mm else ; if there isn't enough space, don't lift. G4 P20 ; wait 20ms G90 ; absolute XYZ moves if job.file.fileName = null ; Check if printing a file G4 P1 ; If you're not printing, don't extrude else if heat.heaters[0].current < 160 ; check for temperature G4 P1 ; dont retract if heaters aren't enabled yet else G1 E-5 F3600 ; retract 5mm ;G1 U{(move.axes[3].max-1)} F6000 ; back off 1mm G91 ; relative positioning G1 H1 U{(move.axes[3].max+100)} F6000 ; home U axis G1 H2 U-2 F3000 ; go back a few mm G1 H1 U10 F600 ; move slowly to Y axis endstop once more (second pass) G90 G4 P0 ; wait for movements to completetpost0.g

; tpost0.g ; called after tool 0 has been selected ; ; Wait for set temperatures to be reached if job.file.fileName = null ; if not printing G4 P1 ; don't extrude elif job.file.fileName != null ; When printing if heat.heaters[0].current > 180 ; and the nozzle is heated to printing temperatures M116 P0 S5 ; wait till printing temperature has been reached within 5c G4 P0 ; wait M83 ; relative extrusion G1 E15 F500 ; extrude 5mm G4 P0 ; wait M106 R2 ; restore fan speed G1 E1 F500 ; extrude 1mm else G4 P1 G4 P0 if job.file.fileName = null ; if not printing if !move.axes[0].homed || !move.axes[1].homed || !move.axes[2].homed || !move.axes[3].homed ; if axes aren't homed G28 ; home all axes else G4 P1 ; wait 1ms ;elif job.file.fileName != null ; When printing ; G4 P1 ; wait 1ms ; G1 R2 Z3 X0 Y0 F6000 ; go back to 3mm above last position ; G4 P0 ; wait ; G1 R2 Z0 ; go back to the Z height of the last printtpost1.g

; tpost1.g ; called after tool 1 has been selected ; ; Wait for set temperatures to be reached if job.file.fileName = null ; if not printing G4 P1 ; don't extrude elif job.file.fileName != null ; When printing if heat.heaters[1].current > 180 ; and the nozzle is heated to printing temperatures M116 P0 S5 ; wait till printing temperature has been reached within 5c G4 P0 ; wait M83 ; relative extrusion G1 E15 F500 ; extrude 5mm G4 P0 ; wait M106 R2 ; restore fan speed G1 E1 F500 ; extrude 1mm else G4 P1 ; wait 1ms G4 P0 ; wait if job.file.fileName = null ; if not printing if !move.axes[0].homed || !move.axes[1].homed || !move.axes[2].homed || !move.axes[3].homed ; if axes aren't homed G28 ; home all axes else G4 P1 ;elif job.file.fileName != null ; When printing ; G4 P1 ; wait 1ms ; G1 R2 Z3 X0 Y0 F6000 ; go back to 3mm above last position ; G4 P0 ; wait ; G1 R2 Z0 ; go back to the Z height of the last print -

@ComedianTF2 said in Adding a Z-hop to IDEX tool changing:

G1 R2 Z3 X0 Y0 F6000

The issue here is of course the "last position" which G1 R2 is restoring to is object a not object b, in fact the position for object b is not yet known when the toolchange is called as it is yet to be sent by the slicer, its sent after to the tool change.

I think there needs to be slicer input here, this could be done in the slicer tool change macros if the the slicer exposes the next tool start position as a variable.

-

@T3P3Tony Thanks, I had assumed so but was a good one to check. Will look at the slicer side for getting things working there.

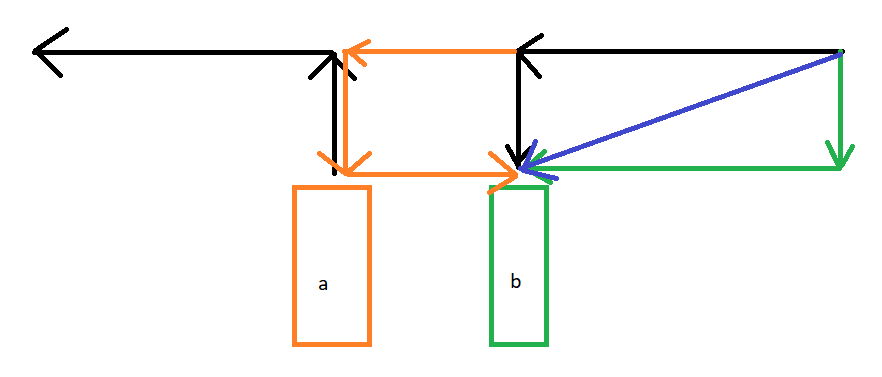

What I do wonder is if it would be possible for the nozzle to do a diagonal move (shown in purple), it always seems to get back to the previous part's Z position before starting no matter what I do. It always does the up/down motion in orange or green

I tried using the following end bit in the tpost0.g and tpost1.g, but it would lower back to the Z position no matter what, even though there isn't anything in the tool changing scripts that would indicate that the Z motion should happen.

elif job.file.fileName != null ; When printing G90 ; absolute positioning if {(move.axes[2].machinePosition) < (move.axes[2].max - 4)} ; if there is enough space G1 Z{(move.axes[2].machinePosition)+3} ; move up 3mm else G4 P1 ; wait 1ms G4 P0 ; wait for moves to complete