nozzle dives almost 4 mm too deep into the bed

-

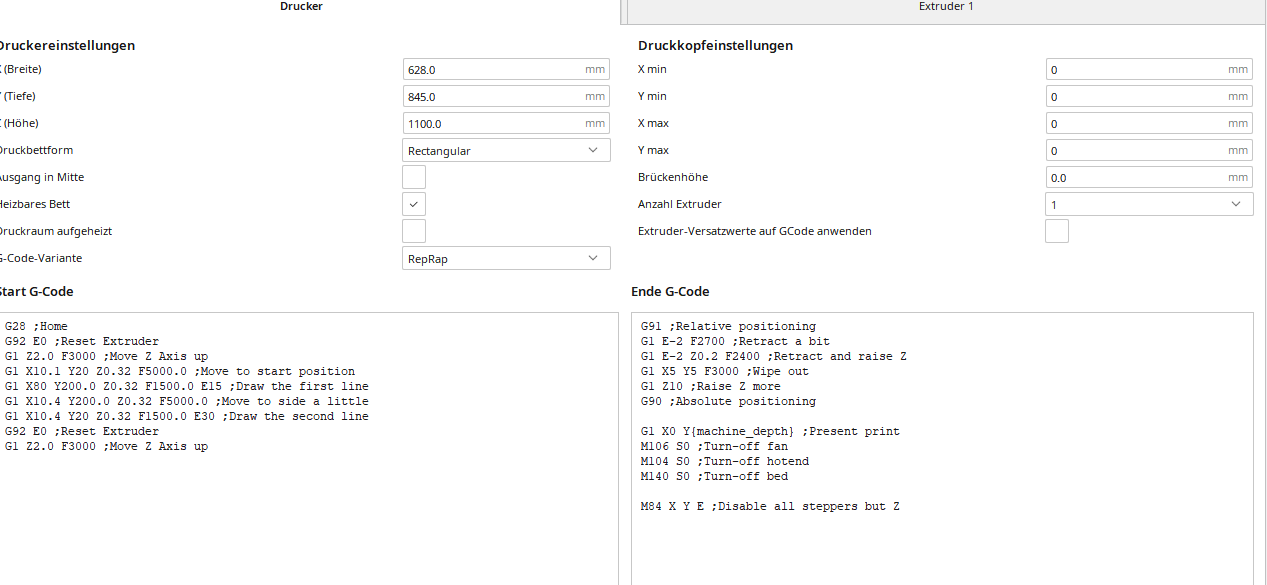

Despite successful bedleveling, the nozzle dives almost 4 mm too deep into the bed. Could this be related to the slicer (Cura) ? Attached are the Cura printer settings, the g-code and the config-g

CCR10_Rahmen100_Duka.gcode

CCR10_Rahmen100_Duka.gcode

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.12 on Wed Aug 24 2022 12:56:11 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"DUKA1300" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P1 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards extruder1

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

;M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm

M92 X80.00 Y80.00 Z640.00 E320.20:320.51 ; set steps per mm

M566 X900.00 Y900.00 Z100.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z40.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1700 E1800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X650 Y770 Z1255 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

;M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop

;M574 Z2 S2 ; configure Z-probe endstop for high end on Z

; Z-Probe

M558 P1 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P1000 X-10 Y95 Z4.869 ; set Z probe trigger value, offset and trigger height

M557 X20:650 Y100:770 S50 ; define mesh grid; Heaters

;M308 S0 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp

;M950 H0 C"e0heat" T1 ; create nozzle heater output on e1heat and map it to sensor 0

;M307 H0 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit

;M143 H0 S250 ; set temperature limit for heater 0 to 250C

M308 S1 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e1heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S250 ; set temperature limit for heater 1 to 250C

M308 S2 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin bedtemp

M950 H2 C"bedheat" T2 ; create bed heater output on bedheat and map it to sensor 2

M307 H2 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H2 ; map heated bed to heater 2

M143 H2 S280 ; set temperature limit for heater 2 to 280C; Fans

M950 F1 C"fan0" Q250 ; create fan 0 on pin fan0 and set its frequency

;M106 P0 S1 H0 T45 ; set fan 0 value. Thermostatic control is turned on

;M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

;M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

;M563 P0 D0 H0 F0 ; define tool 0

;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

;G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H1 F0 ; define tool 1

G10 P1 X45 Y45 Z0 ; set tool 1 axis offsets

G10 P0 R0 S1 ; set initial tool 1 active and standby temperatures to 0C

M591 D1 P1 C"e1-stop" S0 ;R40:120 E3.0 S1 ; Filament Sensor

M568 P1 R160 S0

; Custom settings are not defined; Miscellaneous

M501

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

Post your homing files please.

-

@Phaedrux

For me, the bed moves on the Z-axis. Top point is 0

Here are the home files:; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.3.12 on Wed Aug 24 2022 12:56:11 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H2 Z5 F800 ; lift Z relative to current position

G90 ; absolute positioning

G1 X35 Y25 F800 ; go to first probe point

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

G91 ; relative positioning

G1 Z5 F100 ; lift Z relative to current position

G90 ; absolute positioning; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.3.12 on Wed Aug 24 2022 12:56:11 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H2 Z5 F800 ; lift Z relative to current position

G1 H1 X-633 Y-845 F800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X10 Y10 F800 ; go back a few mm

G1 H1 X-628 Y-845 F400 ; move slowly to X and Y axis endstops once more (second pass)

;G1 H1 Z-1100 F360 ; move Z up stopping at the endstop

G90

G1 X35 Y25 F800

G30 ; absolute positioning

;G92 Z1100 ; set Z position to axis maximum (you may want to adjust this); Uncomment the following lines to lift Z after probing

G91 ; relative positioning

G1 Z5 F100 ; lift Z relative to current position

G90 ; absolute positioning; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.3.12 on Wed Aug 24 2022 12:56:11 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H2 Z5 F800 ; lift Z relative to current position

G1 H1 Y-845 F800 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 Y5 F800 ; go back a few mm

G1 H1 Y-845 F400 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.3.12 on Wed Aug 24 2022 12:56:11 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H2 Z5 F800 ; lift Z relative to current position

G1 H1 X-633 F800 ; move quickly to X axis endstop and stop there (first pass)

G1 H2 X5 F800 ; go back a few mm

G1 H1 X-633 F400 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F800 ; lower Z again

G90 ; absolute positioning -

@axiom said in nozzle dives almost 4 mm too deep into the bed:

; Z-Probe

M558 P1 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P1000 X-10 Y95 Z4.869 ; set Z probe trigger value, offset and trigger heightWhat kind of probe is it? How did you measure the trigger height?

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Z_probe_testing

-

@Phaedrux it is a capacitive sensor. I made the trigger height according to the instructions and he also does a successful bed leveling with 190 measuring points...so it's probably not the sensor

-

When it dives too deep, what Z position does it think it has?

-

-

I think there is something wrong with your capacitive sensor, or it's not picking up your bed surface correctly.

A negative trigger height means just that, it triggers when the nozzle is bellow the surface of the bed, which for some nozzle contact probes is normal and usually a fraction of a mm. -5.5mm is not correct in your case.

So either the probe is completely wrong, or there is something somewhere in your gcode that is setting the nozzle position higher than it actually is.

Can you post your config-override.g?

How exactly did you measure the trigger height?

-

@Phaedrux said in nozzle dives almost 4 mm too deep into the bed:

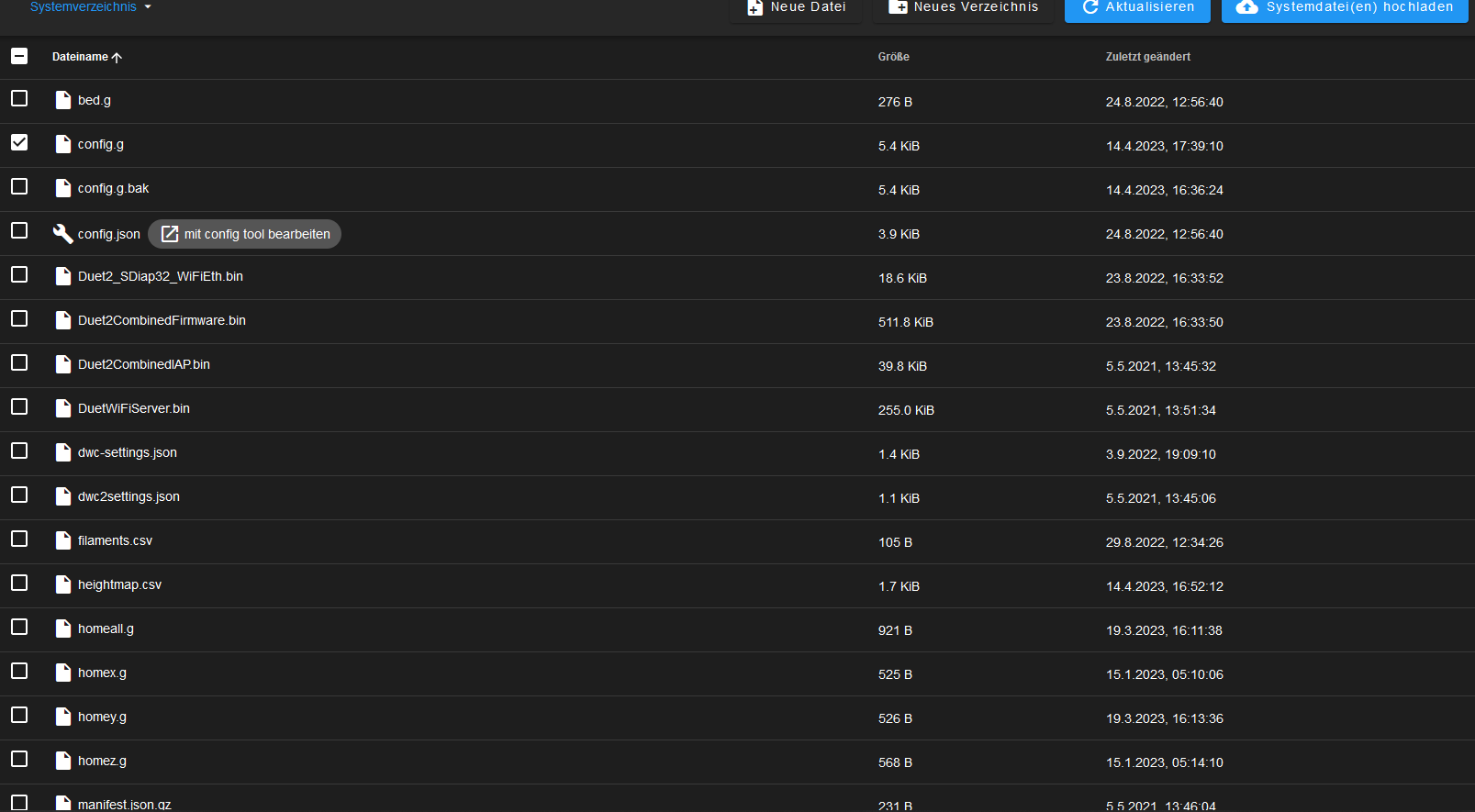

I test the trigger hight exactly according to the instructions you sent me: https://docs.duet3d.com/en/User_manual/Connecting_hardware/Z_probe_testingI don't have a config-override.g. Just a "config.g" and a "config.g.bak"... I attach both.

A true bed leveling works for me without any problems. When I start a job, the nozzle pushes its head up (moves into the bed). If I then adjust the Z-offset manually, it prints its job properly (the dimensions are correct)...however, that's certainly not good for the head if it goes into bed every time.

Here the config files:; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.12 on Wed Aug 24 2022 12:56:11 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"DUKA1300" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P1 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards extruder1

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

;M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm

M92 X80.00 Y80.00 Z640.00 E320.20:320.51 ; set steps per mm

M566 X900.00 Y900.00 Z100.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z40.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1700 E1800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X640 Y760 Z1255 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

;M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop

;M574 Z2 S2 ; configure Z-probe endstop for high end on Z

; Z-Probe

M558 P1 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P1000 X-61 Y-1 Z5.558 ; set Z probe trigger value, offset and trigger height

M557 X15:580 Y15:750 S50 ; define mesh grid; Heaters

;M308 S0 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp

;M950 H0 C"e0heat" T1 ; create nozzle heater output on e1heat and map it to sensor 0

;M307 H0 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit

;M143 H0 S250 ; set temperature limit for heater 0 to 250C

M308 S1 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e1heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S250 ; set temperature limit for heater 1 to 250C

M308 S2 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin bedtemp

M950 H2 C"bedheat" T2 ; create bed heater output on bedheat and map it to sensor 2

M307 H2 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H2 ; map heated bed to heater 2

M143 H2 S280 ; set temperature limit for heater 2 to 280C; Fans

M950 F1 C"fan0" Q250 ; create fan 0 on pin fan0 and set its frequency

;M106 P0 S1 H0 T45 ; set fan 0 value. Thermostatic control is turned on

;M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

;M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

;M563 P0 D0 H0 F0 ; define tool 0

;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

;G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H1 F0 ; define tool 1

G10 P1 X45 Y45 Z0 ; set tool 1 axis offsets

G10 P0 R0 S1 ; set initial tool 1 active and standby temperatures to 0C

M591 D1 P1 C"e1-stop" S0 ;R40:120 E3.0 S1 ; Filament Sensor

M568 P1 R160 S0

; Custom settings are not defined; Miscellaneous

M501

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.12 on Wed Aug 24 2022 12:56:11 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"DUKA1300" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P1 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards extruder1

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

;M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm

M92 X80.00 Y80.00 Z640.00 E320.20:320.51 ; set steps per mm

M566 X900.00 Y900.00 Z100.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z40.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1700 E1800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X640 Y774 Z1255 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

;M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop

;M574 Z2 S2 ; configure Z-probe endstop for high end on Z

; Z-Probe

M558 P1 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P1000 X-61 Y-1 Z5.558 ; set Z probe trigger value, offset and trigger height

M557 X15:580 Y15:750 S50 ; define mesh grid; Heaters

;M308 S0 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp

;M950 H0 C"e0heat" T1 ; create nozzle heater output on e1heat and map it to sensor 0

;M307 H0 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit

;M143 H0 S250 ; set temperature limit for heater 0 to 250C

M308 S1 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e1heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S250 ; set temperature limit for heater 1 to 250C

M308 S2 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin bedtemp

M950 H2 C"bedheat" T2 ; create bed heater output on bedheat and map it to sensor 2

M307 H2 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H2 ; map heated bed to heater 2

M143 H2 S280 ; set temperature limit for heater 2 to 280C; Fans

M950 F1 C"fan0" Q250 ; create fan 0 on pin fan0 and set its frequency

;M106 P0 S1 H0 T45 ; set fan 0 value. Thermostatic control is turned on

;M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

;M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

;M563 P0 D0 H0 F0 ; define tool 0

;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

;G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H1 F0 ; define tool 1

G10 P1 X45 Y45 Z0 ; set tool 1 axis offsets

G10 P0 R0 S1 ; set initial tool 1 active and standby temperatures to 0C

M591 D1 P1 C"e1-stop" S0 ;R40:120 E3.0 S1 ; Filament Sensor

M568 P1 R160 S0

; Custom settings are not defined; Miscellaneous

M501

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@axiom

I discovered that you can create a config.overridge file using the M500 command. I did that but there is not much in it:; config-override.g file generated in response to M500 at 2023-04-15 08:54

; This is a system-generated file - do not edit

; Heater model parameters

M307 H1 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8

M307 H2 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0

; Workplace coordinates

G10 L2 P1 X0.00 Y0.00 Z0.00

G10 L2 P2 X0.00 Y0.00 Z0.00

G10 L2 P3 X0.00 Y0.00 Z0.00

G10 L2 P4 X0.00 Y0.00 Z0.00

G10 L2 P5 X0.00 Y0.00 Z0.00

G10 L2 P6 X0.00 Y0.00 Z0.00

G10 L2 P7 X0.00 Y0.00 Z0.00

G10 L2 P8 X0.00 Y0.00 Z0.00

G10 L2 P9 X0.00 Y0.00 Z0.00 -

If you manually move the nozzle to touch the bed, then send G92 Z0, then jog to Z100, if you measure the distance is it actually 100mm?

If you home X and Y and then send G30 to probe the bed, does Z0 equate to the nozzle touching the bed?

-

@Phaedrux I installed a new probe..that didn't change anything.

if I move the bed with G1 Z40 after executing the G92 Z0 command, the distance is correct. But when I run the G1 Z40 command after homing, the distance is about 5mm too small. -

@axiom said in nozzle dives almost 4 mm too deep into the bed:

But when I run the G1 Z40 command after homing, the distance is about 5mm too small.

That would be because your trigger height is -5mm. You're telling it that the nozzle is 5mm below the surface of the bed when the probe triggers.

Can you try this? Set your probe type to

M558 P0for manual probe mode. Change toG31 X0 Y0 Z0since there are no offsets. Then go through your normal homing and leveling routine. This will prompt you to jog the nozzle down to touch the bed whenever the probe would normally be called. -

@Phaedrux said inDon't get me wrong: I change the M588 and the G31 command in config.g?

Does this mean I should manually check 190 points when leveling bed? -

@Phaedrux I rather have the impression that the value is not being transferred, I can never find the M500 command anywhere....I already sent the code...where should it be with the M500?

-

Yes you need to change the M558 and G31 in config.g

Since the manual probing is very slow, I would also recommend changing the mesh grid size to be much smaller. Maybe a 2x2 grid for now. 190 points would take a very very long time.

@axiom said in nozzle dives almost 4 mm too deep into the bed:

@Phaedrux I rather have the impression that the value is not being transferred, I can never find the M500 command anywhere....I already sent the code...where should it be with the M500?

I'm not sure what you mean. You don't need to use M500 at all for this. M500 is only used to save things that are calculated by the firmware, like heater PID tuning values, etc.

-

@axiom if you want the probe offset saved with M500, use

M500 P31 -

@Phaedrux I think I was able to partially solve the riddle: I thought the M561 command would also delete the trigger values in config.g. You have to manually set the trigger value G31 of Z to 0 before the trigger test. The second thing I did is physically decrease the distance of the sensor. The disadvantage of a capacitive sensor is that the heat from the bed will greatly reduce the life of the sensor. So I'll be looking for a new sensor system in the long term...I've started reading about the piezo technology, but I suspect that the one on my Volcano hotend is too big...but in any case, the printer is running reasonably well now... ..just to understand: Are the values after the mesh bed compensation automatically taken into account during the job and are the unevenness compensated?

-

@axiom said in nozzle dives almost 4 mm too deep into the bed:

just to understand: Are the values after the mesh bed compensation automatically taken into account during the job and are the unevenness compensated?

Yes, that's the point of the mesh.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved

-

@Phaedrux thanks for your patience ! Maybe you could set that with z=0 in the config.g for complete beginners like me in the documentation?

-

undefined jp.douarvil 0 referenced this topic

undefined jp.douarvil 0 referenced this topic

-

undefined jp.douarvil 0 referenced this topic

undefined jp.douarvil 0 referenced this topic