M701 producing unexpected console messages.

-

I'm working on setting up my filaments and their automated load/unload files as well as config files with temperatures and such.

Currently, I am getting unexpected messages in my console from these commands, and I am not sure why they are showing up.

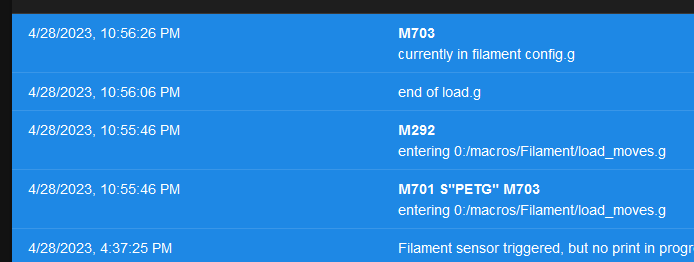

When I run a filament load from DWC, it runs my load.g, and then I echo when I am entering a macro for the filament load moves. This is what I get in the console at that point.

I don't understand why there is a M703 in there, and I do not understand where the M292 is coming from. Documentation says that is comes from the user interface to acknowledge a blocking message, but I am not acknowledging a blocking message from the user interface.

It also appears that M703 does not run. None of my temperatures or echos return from my config.g.

Here are the relevant files.

load.g

;echo "entering petg load.g" var TargetTemp = 250 var thisHeater = tools[state.currentTool].heaters[0] M291 P"Please wait while the nozzle is being heated." R"Loading PETG" T5 ; display message M568 S{var.TargetTemp} A2 ; set current tool active temperature to TargetTemp and activate tool ;var thisHeater = tools[state.currentTool].heaters[0] ;show progress of heating from lower temp while (heat.heaters[tools[state.currentTool].heaters[0]].current < var.TargetTemp) M291 R"Preheating.. Please wait" P{"Current temp = " ^ heat.heaters[var.thisHeater].current ^ " : target = " ^ var.TargetTemp} S0 T2 G4 S2 ;if (heat.heaters[var.thisHeater].current) < (var.TargetTemp) ; echo "waiting for temp in if statement" ; M116 ; wait for temp M291 P"Press OK to feed filament" R"Loading PETG" S2 ; display message echo "entering 0:/macros/Filament/load_moves.g" M98 P"0:/macros/Filament/load_moves.g" ; run file at path echo "entering config.g" M703load_moves.g

M83 ; Extruder to relative mode G1 E55 F200 ; Feed 55mm of filament at 200mm/min G4 P1000 ; Wait one second G1 E-1 F1800 ; Retract 10mm of filament at 1800mm/min M400 ; Wait for moves to complete M568 A0 ; Turn tool offconfig.g (for the filament)

;M207 S0.9 R0.0 F3000 T3000 Z0.0 ; firmware retraction settings for PETG ;M572 D0 S0.1 ; Pressure Advance ;M307 H0 A214.3 C641.7 D1.3 S1.00 V24.0 B0 ; Bed PID tune for 120c ;M307 H1 A491.0 C190.9 D2.8 S1.00 V23.9 B0 ; Hot end PID tune at 280c ;M566 X1200 Y1200 Z60 E3000 ; jerk settings for PETG ;M204 P1000 T4000 ; Set printing and travel accelerations echo "currently in filament config.g" M140 S85 ; set bed temp M568 P0 R170 S250 A0 ; set extruder temp M116 H0 ; wait for bed tempI also have M703 in my tpost0.g, along with a M116. As you can see, the echo in my filament config.g never returns to the console, so I'm assuming the filament config.g is never run, even though I have it in both the load.g and tpost0.g.

Any idea what I am missing here? Current firmware is 3.4.5 for both dwc and duet 3 6HC

Thank you

-

@Surgikill M703 cannot be used in filament load macros because the filament isn't updated before load.g finishes. That's why DWC sends M701 and then M703.

-

@chrishamm Okay, but if DWC is sending M701 and M703, then it should be running config.g, but it isn't. Nowhere in my console output does my

echo "currently in filament config.g"show up. I also still have no clue where the M292 is coming from, I can't find it anywhere in any of my files, so I am guessing it might be something coded into DWC? -

@Surgikill M292 is sent by DWC to acknowledge message boxes. From your report it looks like you call M701 manually and try to call M703 at the end of load.g, which is incorrect. The best place to put M703 is tpostN.g so that filament settings can be applied automatically to the selected tool.

Are you at least on RepRapFirmware and DuetWebControl 3.4.5? Please share your machine config.g as well.

-

@chrishamm I'm not trying to be a smartass, but I posted my firmware and DWC version in the original post, as well as stated that M703 is included in tpost0.g.

M701 is being called through DWC using the load filament command under the tool. Even removing M703 does not change the behavior. I did notice that if I run T0, it does not run tpost0.g. I first have to deselect the tool, and then run T0 again in order for tpost0.g to be run.

printer config.g

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Mon Dec 26 2022 22:49:35 GMT-0500 (Eastern Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Magnum Opus" ; set printer name M669 K1 ; select CoreXY mode ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Independent Z-axis configuration M671 X-87.25:-87.25:382.75:382.75 Y-113.2:356.8:356.8:-113.2 S10 ; leadscrews at front left, rear left, rear right and front right ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.5 S0 ; physical drive 0.5 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P121.0 S0 ; physical drive 121.0 goes forwards M569 P0.4 S1 ; physical drive 0.4 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M584 X0.5 Y0.0 Z0.1:0.2:0.3:0.4 E121.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80 Y80 Z400 E409 ; set steps per mm M566 X1200 Y1200 Z120 E2000 ; set maximum instantaneous speed changes (mm/min) M203 X30000 Y30000 Z1200 E7200 ; set maximum speeds (mm/min) M201 X4000 Y4000 Z600 E20000 ; set accelerations (mm/s^2) M906 X1800 Y1800 Z1300 E1100 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X320 Y315 Z390 S0 ; set axis maxima ; Endstops M574 X1 S1 P"121.io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin 121.io1.in M574 Y1 S1 P"io8.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io8.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 K0 P8 C"^121.io0.in" H10 F300:120 T12000 A3 S0.02 ; set Z probe type to unmodulated and the dive height + speeds ; K0 for probe 0, P5 for NC switch, C for input pin, ; ^ for enabling the native pullup resistor on Duet 2 ; hardware running RRF3 ; H dive height of 8mm, F300 probing speed 5mm/sec, ; T9000 travel speed 150mm/sec, ; A3 number of probes 1, S0.01 max tolerance of 0.01 G31 K0 P500 X-0.55 Y-33.74 Z6.05 ; set Z probe trigger value, offset and trigger height ; CHECK for LOOSE things first! set Z probe trigger ; value, offset and trigger height. Higher numbers ; makes nozzle closer to bed ; switch plunger is 0.25mm to the LEFT and 41.28mm BEHIND ; the nozzle. Switch triggers 0.9mm BELOW nozzle ; https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe#Section_ M557 X21:301 Y11:281 P15 ; define mesh grid ; Heaters ;Bed M308 S0 P"temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 120C ;Tool 0 (volcano hemera) M308 S1 P"121.temp0" Y"pt1000" ; configure sensor 1 as pt1000 on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C M591 D0 P1 C"121.io1.in" S1 ; filament monitoring enabled (S) on extruder 0 (D) with active high value (P) ; Fans M950 F0 C"out9" Q500 ; create fan 2 on pin out9 and set its frequency M106 P0 C"CPAP Blower" S0 L0.15 X1.0 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F1 C"121.out2" Q500 ; create fan 1 on pin 121.out2 and set its frequency M106 P1 C"Hotend Fan" S1.0 H1 T55 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Hemera Volcano" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;G4 P1000 M955 P121.0 I10 ; accelerometer orientation M593 P"ei3" F46 ; input shaping configuration ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory T0 ; select first tool -

@Surgikill

When you select "Load filament" or "Change filament" in DWC, it doesn't just issue one command.

If you have no tool selected "Load Filament" will send

T0 M701 S"PLA" M703

If you have a tool selected it will send

M701 S"PLA" M703 -

@OwenD So then why is it not running the config.g for the filament that is being loaded? Both of those scenarios have M703, yet the echo in my filament config.g does not return to the console, which means the file isn't being run. Here is what it looks like when I load filament.

The last M703 at 10:56:26 was sent manually by me typing it into the console, so the echo works, but it's not run during the load sequence.

-

@Surgikill

There appears to be a bug in RRF 3.5b3 whereby multiple commands on a single line aren't all executed.

I haven't figured out the exact conditions.

So

M702 M701 S"PETG" M703won't work

G28 M400 G1 X10 Y10won't work

but

G1 X50 Y50 M400 G1 X10 Y10does work -

@OwenD I'm on 3.4.5, so not sure if the bug is exclusive to b3, or if it goes farther back. I can try manually entering M701 S"filament" M703, and see what it does.