Hey all,

I'm trying to figure out an issue I am having with filament changes. I'm not sure if this is a new issue, or if I just never noticed this before.

The way I have my duet configured is to use filaments stored on the machine.

I have a load.g, unload.g, and config.g for each filament.

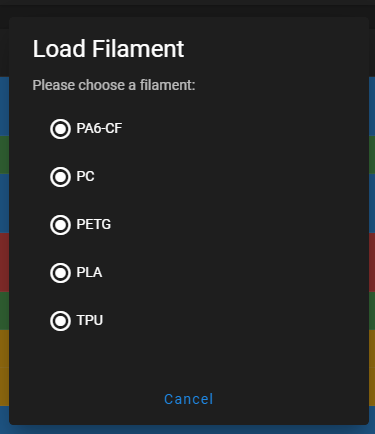

Now, the problems arise when trying to load/unload filament from DWC.

First, if I select the filament from DWC and click 'unload', it heats the bed and waits for the bed to reach temperature first. Is this intended? This is even before it executes M702. This seems counterintuitive. Is this being influenced by tool change macros? When I run T0, it puts the bed into standby mode. However, my toolchange macros don't call for that to happen.

Also, when loading filament, it does not load the selected filament parameters before loading.

For example, if I have PLA loaded, with an active temp of 230, it will unload the PLA, keep the active temp of 230, then when it goes to load PETG it will keep the active temp of 230, even when running M703. I am assuming that this is because the PETG is not 'loaded' yet according to the system. Only AFTER all the macros are done, does running M703 update the temps.

Can anybody explain the logic here and help me figure out a way to get this to work, without needing to manually set temps in a load macro?

Here is load.g

M98 P"0:/macros/Filament/universal_load.g"

and here is the 'universal_load.g' macro

M703

M291 R{"Loading " ^ move.extruders[state.currentTool].filament} P"Please insert filament and press OK" S3

M302 P1 ;allow cold extrusion

G1 E10 F200 ; Feed 30mm of filament at 200mm/min

M302 P0 ;disallow cold extrusion

M568 A2

echo "set tool heater to active"

M98 P"0:/sys/pause_position.g"

var TargetTemp = tools[state.currentTool].active[0] ;set TargetTemp to current tool active temp

var thisHeater = tools[state.currentTool].heaters[0]

while (heat.heaters[tools[state.currentTool].heaters[0]].current < var.TargetTemp)

M291 R"Waiting for temperature to be reached." P{"Current: " ^ heat.heaters[var.thisHeater].current ^ " | Target: " ^ var.TargetTemp} S0 T2

G4 S2

M83 ; Extruder to relative mode

G1 E60 F200 ; Feed 60mm of filament at 200mm/min

G4 P10 ; Wait 10ms

while iterations >= 0

M291 P"Is color correct?" R"Color Change" S4 K{"Yes","No"}

if (input == 0)

break

if (input == 1)

G1 E40 F200 ; Feed 40mm of filament at 200mm/min

G4 P10 ; Wait 10ms

G1 E-1 F1800 ; Retract 1mm of filament at 1800mm/min

M400 ; Wait for moves to complete

M568 A0 ; Turn tool off

unload.g

M98 P"0:/macros/Filament/universal_unload.g"

and 'universal_unload.g' macro

;; Universal unload.g - direct all other filament unoad.g instances to this file

;;

;M929 P"0:/macros/filament/unloadeventlog.txt" S3

echo "entering 0:/macros/filament/universal_unload.g"

M703

if state.currentTool==-1

M291 R"No Tool" P"No tool selected. Press OK to unload tool 0" S2

T0 P0

if (move.extruders[state.currentTool].filament == "")

M291 R"Error" P"No filament loaded. Unload aborted" S2 T2

M99

M98 P"0:/sys/pause_position.g"

var TargetTemp = tools[state.currentTool].active[state.currentTool]

M568 A2; Heat current tool to active temp

G4 S3

var thisHeater = tools[state.currentTool].heaters[0]

;show progress of heating from lower temp

while (heat.heaters[tools[state.currentTool].heaters[0]].current < var.TargetTemp)

M291 R"Waiting for temperature to be reached." P{"Current: " ^ heat.heaters[var.thisHeater].current ^ " | Target: " ^ var.TargetTemp} S0 T2

G4 S1

M291 R{"Unloading " ^ move.extruders[state.currentTool].filament} P"Retracting..." S0 T5

M98 P"0:/macros/Filament/unload_moves.g"

M568 P{state.currentTool} A0 ; Turn current tool off

tpost0.g

; tpost0.g

; called after tool 0 has been selected

;

; generated by RepRapFirmware Configuration Tool v3.3.15 on Mon Dec 26 2022 22:40:57 GMT-0500 (Eastern Standard Time)

; Wait for set temperatures to be reached

M703

M116 P0