need help on printing sinlge wall

-

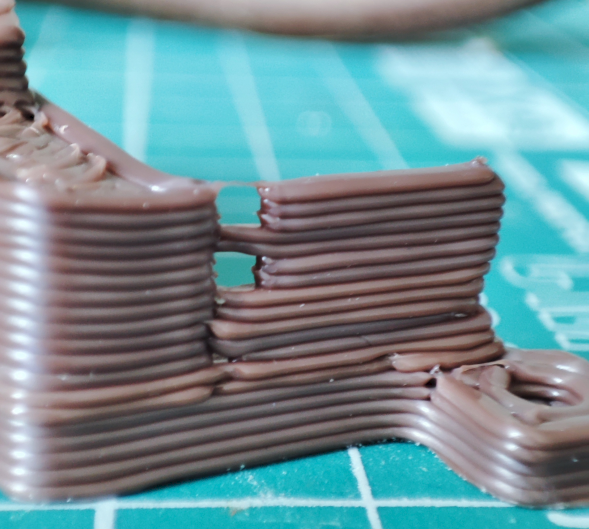

I'm trying to reduce printing time and used 1.0 mm head. This leads to insufficient extrusion near single wall seam.

HW: duet3d RRF3 + prusa slicer. Layer height is 0,6.

pressure advance is M572 D0 S0.1 (im not sure it effects this issue)

extruder is direct (zesty nimble)In slicer i tested with and without 'detect slim walls' - but result is the same.

With 0,8 head and layer 0,45 it works well, but at a cost of +40% print time

Please advise which options i can change in slicer or duet config to get single line solid wall, without gaps.

Thanks!

-

@c310 you'll need to either retune pressure advance or remove it fully.

-

With a 1 mm nozzle it is going to be tricky to tune that problem out, especially because of single wall. I have struggled with seams in walls with a 1mm nozzle for years. Sometimes you can tune it to work on your specific print, but the settings often won't work well for a different print, and you're definitely not going to save any time because of all the tweaking.

There might be some slicer settings that can help. I recently sliced a box with 2 perimeters/walls using Cura and the setting "optimize wall printing order" and "seam corner preference- hide seam" worked nicely to prevent the seam from showing. It prints the two walls by starting at the seam location (inside a sharp concave corner), makes one pass around the perimeter, then when it gets back to the seam location, reverses and prints the second wall. When it gets to the seam again, the bed drops and it starts printing the wall on the next layer, so there's no travel , no retraction, and no gaps - the filament keeps flowing.

-

try a slicer with Arachne for better thin wall support?

-

@mrehorstdmd Thank you very much for sharing. I fighted the issue half a day and finally used your advise - do not bother ) and made a model with 2 walls that printed without issues.