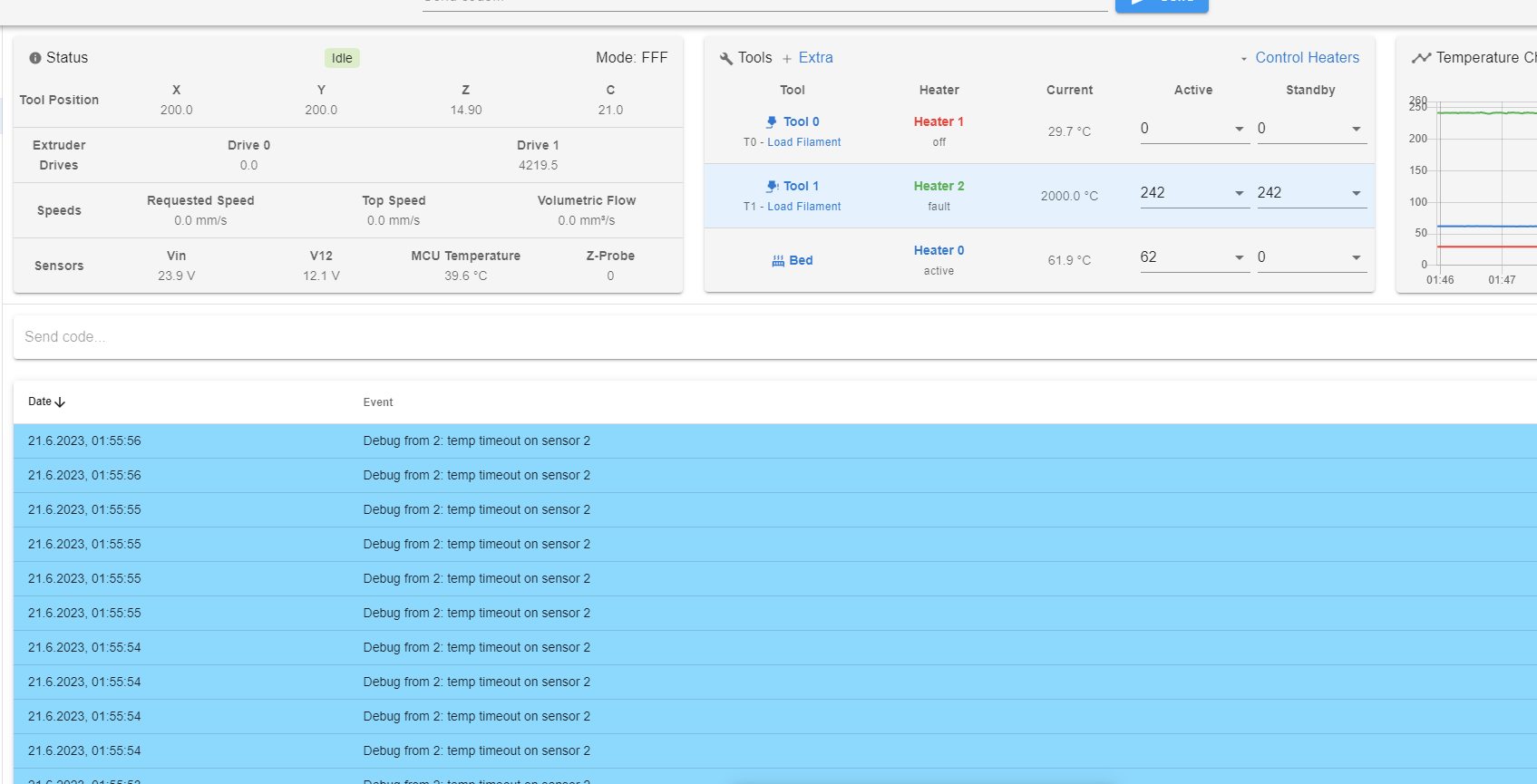

Heater time out - debug from 2

-

Hello;

what does this exactly mean?thanks

R.G.

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves ; Drives ;closed loop M569.1 P20.0 T2 C1000 E12:8 R70 I3500 D0.1 H20 ; Configure the 1HCL board at CAN address.20quadrature encoder 128 steps/motor full M569.1 P21.0 T2 C1000 E12:8 R70 I3500 D0.1 H20 ; Configure the 1HCL board at CAN address.21quadrature encoder 128 steps/motor full step. M569.1 P30.0 T2 C1000 E12:8 R70 I3500 D0.1 H20 ; Configure the 1HCL board at CAN address.21quadrature encoder 128 steps/motor full step. M569 P20.0 D4 S0 ; Configure the motor on the 1HCL at can address 20 as being in closed-loop drive mode (D4) and not reversed (S1) M569 P21.0 D4 S1 ; Configure the motor on the 1HCL at can address 21 as being in closed-loop drive mode (D4) and not reversed (S1) M569 P30.0 D4 S1 ; Configure the motor on the 1HCL at can address 21 as being in closed-loop drive mode (D4) and not reversed (S1) Other drives ; open loop; M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.2 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S1 M569 P0.5 S0 M569 P100.0 S0 ; physical drive 0.2 goes forwards M569 P110.0 S0 D2 ; physical drive 0.2 goes forwards M584 X30.0 Y20.0:21.0 Z0.0:0.1:0.2:0.3 C0.5 E100.0:110.0 ; set drive mapping M350 X32 Y32 Z16 E16 I1 ; configure microstepping with interpolation M92 X160 Y160 Z640 C91.022 E400:690 ; set steps per mm M566 X4000.00 Y4000.00 Z2000.00 C3000 E3000.00:3000.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z270.00 C10000 E24000.00:24000.00 ; set maximum speeds (mm/min) M201 X3500.00 Y3000.00 Z2000.00 C400 E4000.00:4000.00 ; set accelerations (mm/s^2) M906 X2000 Y3600 Z2300 C550 E800:1200 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S300 ; Set idle timeout M671 X-100:-100:1180:1180 Y-100:1180:1180:-100 S20 ; leadscrews at front left1 and n´back2. back rigth3 and front4 M915 P0.5 C S0 F0 R1 ; Axis Limits M208 X0 Y-100 Z0 S1 ; set axis minima M208 X1000 Y1030 Z850 S0 ; set axis maxima ; Endstops M574 C1 S3 M574 X2 S1 P"^30.io1.in" ; configure active-high endstop for high end on X via pin ^io3.in M574 Y2 S1 P"^20.io1.in+21.io1.in" ; configure active-high endstop for high end on Y via pin ^io1.in ; Z probe M558 P5 C"0.io1.in" H8 F2000 I0 T5000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds G31 P200 X5 Y30 Z0 ; Set Z probe trigger value, offset and trigger height; Z probe M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters M557 X50:800 Y50:800 S37.5 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M140 H0 M307 H0 R0.468 K0.275:0.000 D19.70 E1.35 S1.00 B0 ; disable bang-bang mode for the bed heater and set PWM limit M143 H0 S120 M308 S1 P"100.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as PT1000 on pin 121.temp0 M950 H1 C"100.out0" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B1 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S260 M308 S2 P"110.temp0" Y"pt1000" ; configure sensor 2 as PT1000 on pin 121.temp0 M950 H2 C"2.out0" T2 ; create nozzle heater output on out1 and map it to sensor 2 M307 H2 R2.655 K0.412:0.000 D6.50 E1.35 S1.00 B0 ; disable bang-bang mode for heater and set PWM limit M143 H2 S255 ; set temperature limit for heater 1 to 250C ; Fans M950 F0 C"100.out2" Q500 ; create fan 0 on pin 100.out1 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M563 P0 D0 H1 ; tool uses extruder 0, heater 1 M950 F1 C"100.out1" Q500 ; create fan 1 on pin 100.out2 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M563 P0 D0 H1 F1 ; tool uses extruder 0, heater 1 M950 F2 C"110.out2" Q500 ; create fan 2 on pin 101.out1 and set its frequency M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off M563 P1 D1 H2 ; tool uses extruder 0, heater 2 M950 F3 C"110.out1" Q500 ; create fan 3 on pin 101.out2 and set its frequency M106 P3 S1 H2 T45 ; set fan 3 value. Thermostatic control is turned on M563 P1 D1 H2 F2 ; tool uses extruder 1, heater 2 ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X-9 Y-39 Z-4.56 ; set initial tool 0 active and standby temperatures to 0C G10 P0 R0 S0 M955 P100.00 I20 M563 P1 D1 H2 F2 ; define tool 1 ; set initial tool 0 active and standby temperatures to 0C G10 P1 X-76.9 Y-78.7 Z-20 G10 P1 R0 S0 -

@IndeX4D the message is normally benign, see https://forum.duet3d.com/topic/32696/known-issues-in-firmware-3-5-0-beta-4?_=168737359960. However, you have a heater fault that indicates an issue with the temperature sensor (2000C reading). What type of sensor is it?

-

@dc42

thank you. changing M593 is helpful at the moment.

It´s a pt1000 from STD& hotend.