tangential knife support? Newbie questions

-

Hey all! Looking for help and advice.

Im currently looking to expand our lasering business and buying a CNC. Im really only interested in cutting foam board, from say 3mm -10mm thick, and I need the quality of cut to be perfect, and I have lots of tight/accurate angles that I need replicating. A drag knife probably won't cut it (pun!)

So, (at the moment) I'm looking at buying a workbee which I believe comes with a Duet controller, and I want to combine this with a Oscillating Tangential Knife (OTK-3) from Stepcraft*

Stepcraft recommends this runs from a UCCNC board, which is what their machines use. But I've spoken to Stepcraft technical and they tell me:

"The OTK can be used on different machines as long as on one side the necessary signals according to the manual can be provided and on the other side the used CNC controller software offers tangential knife functionality."

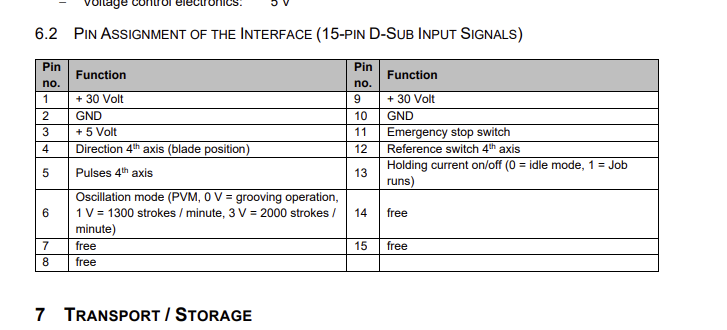

It looks to be the knife is using one motor for rotation and another motor for oscillation. The knife uses a D-Sub-15 connection, no idea how this connects to the board - does anyone know?

Now with all that in mind, is buying a workbee with a duet board going to work do you think?

https://shop.stepcraft-systems.com/Oscillating-Tangential-Knife-OTK-3-for-D-Series-and-M-Series

*if anyone wondering I had toyed with the idea of buying a Stepcraft CNC, but sadly it's pretty expensive and thanks to Brexit (the gift that keeps on giving) import duties and vat into the UK are probably going to push it outside of our budget.

-

@mattyd Looking at the product page, https://shop.stepcraft-systems.com/Oscillating-Tangential-Knife-OTK-3-for-D-Series-and-M-Series, it looks like the knife is controlled by two stepper motors. I'd guess that the D-sub connector carries the four wires needed for each stepper motor, and possibly wires for the endstops for each motor.

As such, it should be easy to connect to a Duet controller, but you will need the pinout of the D-sub connector. Configuring the two motors is also straightforward: the one used for rotation can be set up as a rotational axis, the other will depend on the software used to control the knife.

What software will you use to create code to control the knife? If you are using Stepcraft's software, getting a sample of the output it uses would be good, assuming it uses Gcode. Whatever software you use needs to use Gcode to tell the axes what to do. With a sample, you can be confident that you can configure the Duet to work.

Edit: Also, have a look at other threads on the forum that discuss tangential knife control: https://forum.duet3d.com/search/?term=tangential knife&in=titlesposts

Ian

-

@droftarts Thanks for the reply Ian! That's super helpful and pretty encouraging.

I'm pretty new to this (but a fast learner).

I found the breakdown of the D-Sub pins. Hopefully, this will give some insight into how to connect it to the Duet.

As for software - Ive not actually gotten to that stage yet! but any advice would be appreciated

-

@mattyd That's interesting. It looks like the 4th axis (rotation) has a stepper driver in the unit, and is receiving step and direction commands from the controller, rather than the stepper motor being wired back to the controller directly. There's also an endstop ("reference switch 4th axis") and emergency stop switches. The oscillation motor appears to need a voltage signal (it may work with PWM, but may need a PWM to voltage converter) to control the speed. You'll need a 30V PSU, too.

The alternative is to remove their electronics, and wire motors and switches directly back to the Duet. It may be why this cutter is expensive; because it has it's own electronics. There don't seem to be too many oscillating knife projects, this is the only one I did find (most others are tangential drag knives): https://hackaday.com/2020/02/27/tangental-oscillating-cutting-knife-makes-parts-from-the-ups-and-downs/

I don't have any experience of the software used on these machines, so perhaps looking at Stepcraft's would be a good first step, which may output what is needed to run the 4th axis. Most CNC software works in 3 axes (eg Vcarve, Fusion 360), so you need a post-processor that calculate the 4th axis position, which is often just an Excel script. If you already have CNC tool path generation software, you can use this method to produce Gcode to run this.

Ian

-

@droftarts Ahhhhh. Just looked at the design and the Iges files and that looks pretty simple build. This might be a good option I think. Thank you

-

@droftarts said in tangential knife support? Newbie questions:

The oscillation motor appears to need a voltage signal (it may work with PWM, but may need a PWM to voltage converter) to control the speed

It probably isn't a motor but a simple solenoid/linear actuator?That would work with PWM when driven directly by Duet (heater port)//edit I should've checked the product page. Why do they use a heavy stepper for such a simple task?

-

@o_lampe said in tangential knife support? Newbie questions:

@droftarts said in tangential knife support? Newbie questions:

The oscillation motor appears to need a voltage signal (it may work with PWM, but may need a PWM to voltage converter) to control the speed

It probably isn't a motor but a simple solenoid/linear actuator?That would work with PWM when driven directly by Duet (heater port)//edit I should've checked the product page. Why do they use a heavy stepper for such a simple task?

not a clue! though I think on their main desktop cncs they use two motors for each axis.

-

undefined droftarts referenced this topic

undefined droftarts referenced this topic