Many errors during configuration with RRF tool

-

This post is deleted! -

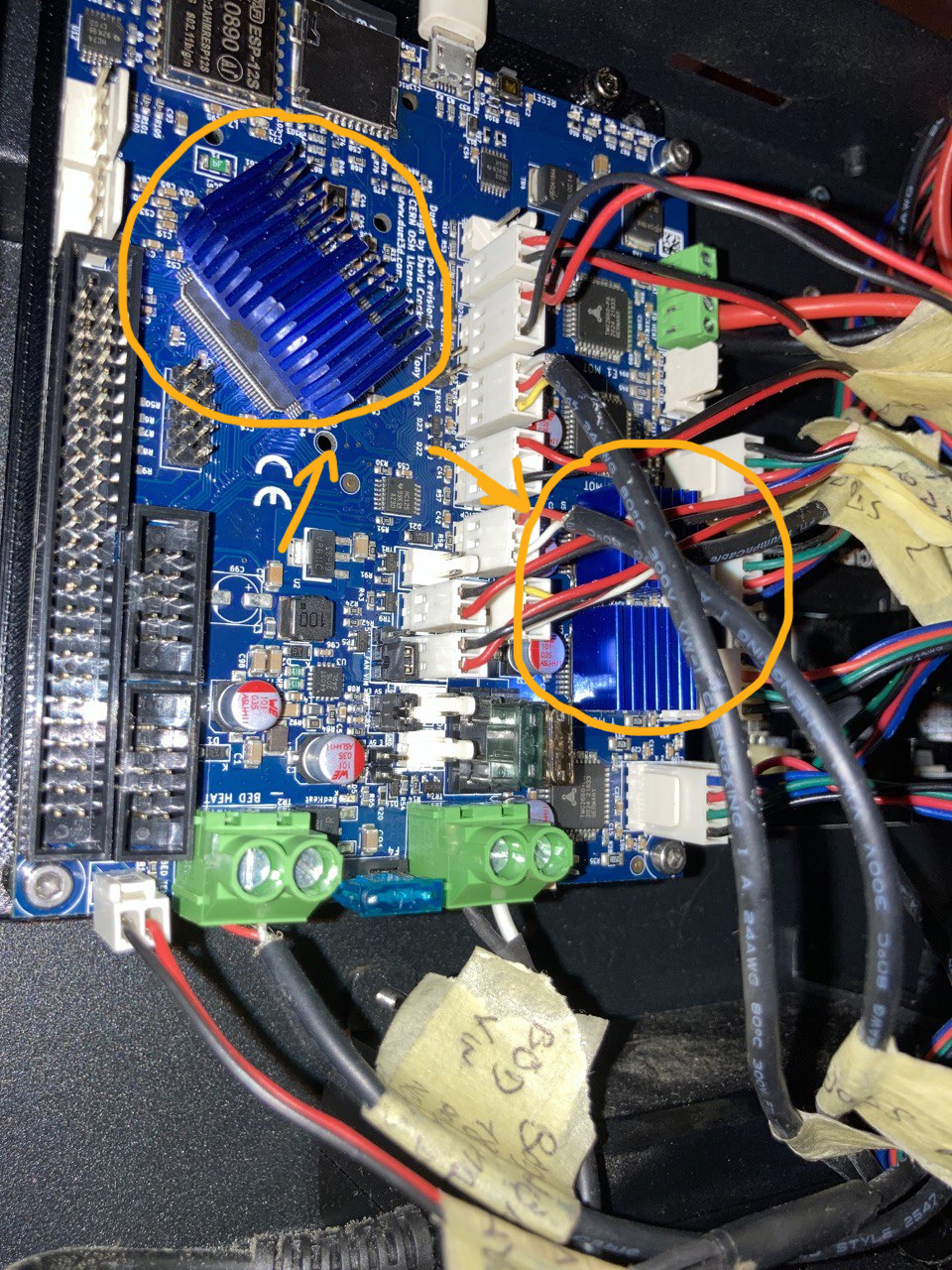

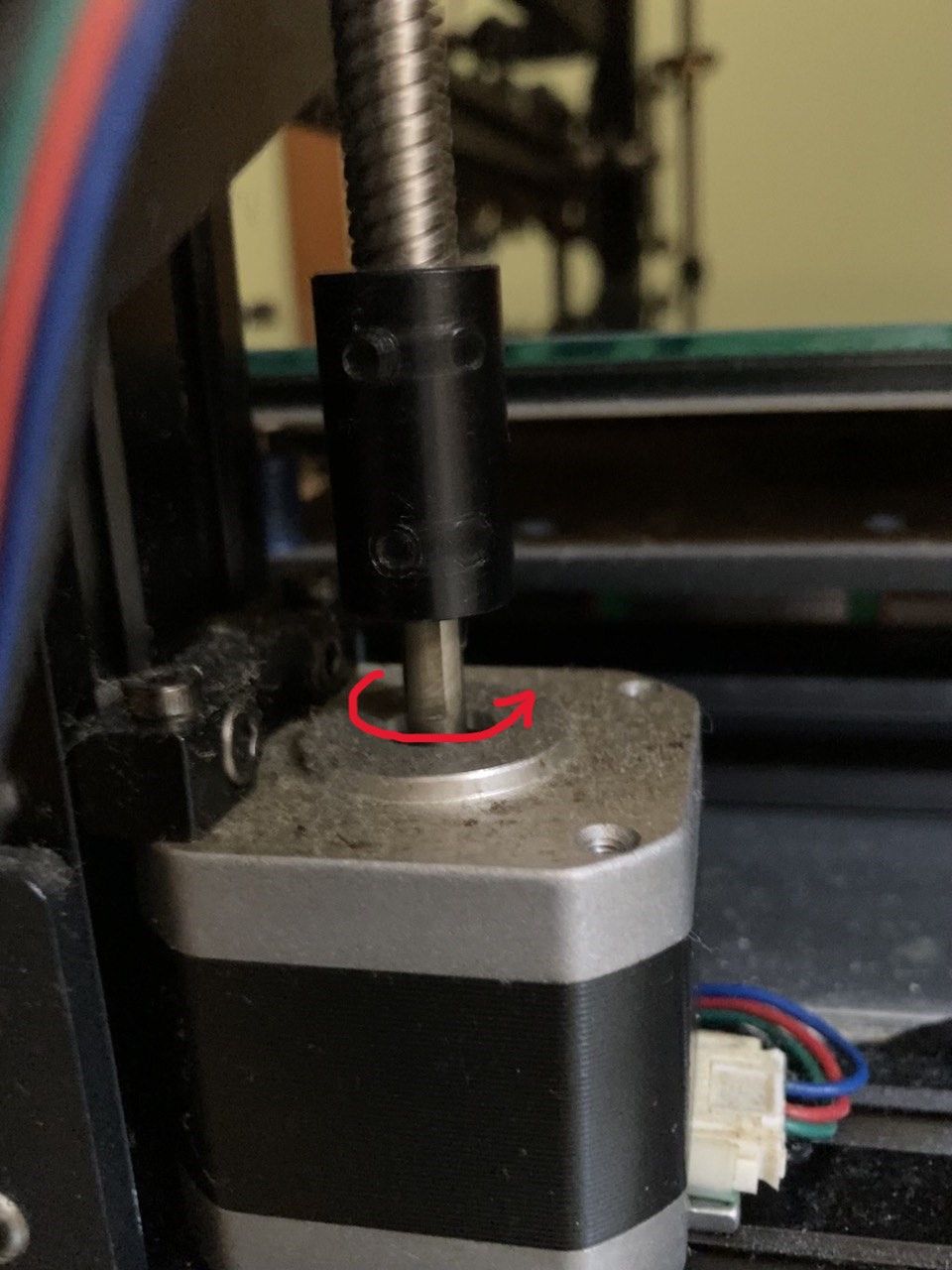

@Herve_Smith I'm sorry, I hadn't understend your suggestion. Now I get you. You are talking about this picture I posted, right?

But I think you're talking about those on bottom right.

From the person I bought this Chiron, I know that Duet 2 wifi was already kitted with "heat-sinks" and he attach them somewhere without reason.

Effectly is a verygood suggestion. So if I'll deattach them, there is any other good position wher to place them? -

@Phaedrux

Done! Now it is better. The z-axis works together, but I'm not sure they are leveled to the plate. I took a measure and there is a gap of 3.4 mm between the R and the L side.With regards the heaters on the extruder and on the bed: the extruder heater works, while for the bed heater, I run command M303, find the new report M307 and save it with M500. Now I think they work properly.

What can I do to recalibrate the zero and the levelling?

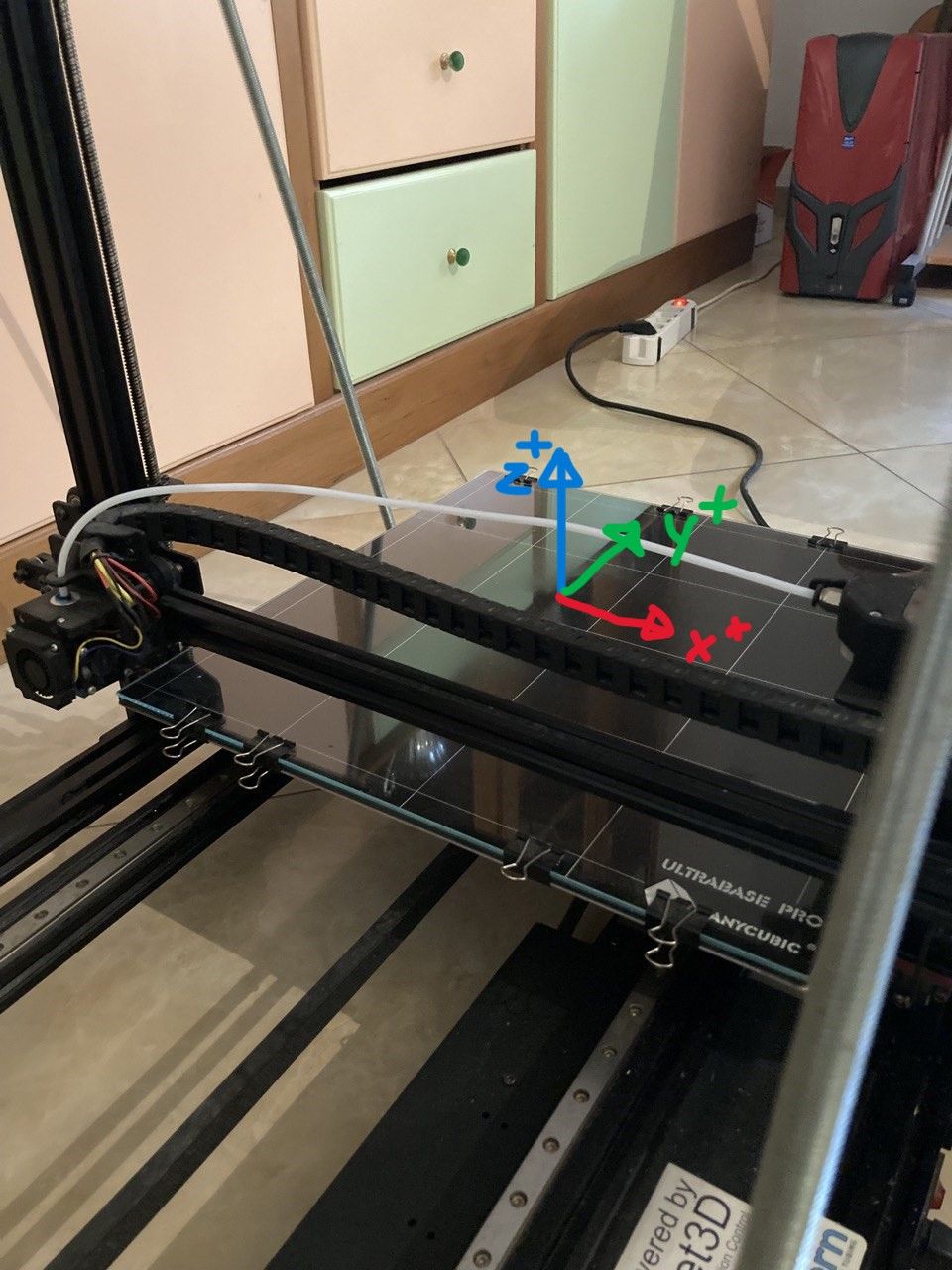

An other dubt about the axis is the verse. What is corret verse for the WCS? I mean:- z positive up or down?

- x positive right or left?

- y positive forward or back?

-

@genioluiz7 said in Many errors during configuration with RRF tool:

z positive up or down?

x positive right or left?

y positive forward or back?Z+ should move the extruder up away from the bed.

X+ should move the extruder to the right

Y+ should move the extruder to the back of the bed, which can be confusing because it moves the bed forward. But you need to the of the motion as moving the print head, not the bed.

XY 0,0 should be the front left corner of the bed, so a Y+ movement should move the print head towards the back.

Take a look at the config.g file that Herve posted above. Compare it to your own.

Post your config.g here by copy and paste the text so we can see what you have. Do the same for your homex.g homey.g homez.g and homeall.g files so we can see how those are working.

And finally please go to the console tab in DWC and send M122 and copy and paste the result here. Then send M98 P"config.g" and copy and paste the result as well.

-

@Phaedrux

Info requested are following:- config.g

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 ; set motor currents (mA)

M84 S0 ; Disable motor idle current reduction; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X400 Y400 Z440 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin zstop; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:385 Y15:385 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss- homeall.g

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Fri Aug 04 2023 10:36:29 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-405 Y-405 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-405 Y-405 F360 ; move slowly to X and Y axis endstops once more (second pass)

G1 H1 Z-445 F360 ; move Z down stopping at the endstop

G90 ; absolute positioning

G92 Z0 ; set Z position to axis minimum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning- homex.g

; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Fri Aug 04 2023 10:36:29 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-405 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 H2 X5 F6000 ; go back a few mm

G1 H1 X-405 F360 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning- homey.g

; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Fri Aug 04 2023 10:36:29 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 Y-405 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 Y5 F6000 ; go back a few mm

G1 H1 Y-405 F360 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning- homez.g

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Fri Aug 04 2023 10:36:29 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 Z-445 F1800 ; move Z down until the endstop is triggered

G92 Z0 ; set Z position to axis minimum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioningM122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.6 (2023-07-21 14:08:28) running on Duet WiFi 1.02 or later

Board ID: 0JD0M-9P6M2-NW4SN-6J1DG-3SD6J-TUT3L

Used output buffers: 1 of 26 (17 max)

=== RTOS ===

Static ram: 23896

Dynamic ram: 75148 of which 0 recycled

Never used RAM 12964, free system stack 152 words

Tasks: NETWORK(notifyWait,13.8%,237) HEAT(notifyWait,0.0%,333) Move(notifyWait,0.0%,314) MAIN(running,86.0%,436) IDLE(ready,0.2%,30), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:12:09 ago, cause: power up

Last software reset at 2023-08-04 10:36, reason: User, GCodes spinning, available RAM 12964, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Step timer max interval 0

MCU temperature: min 29.0, current 32.0, max 32.5

Supply voltage: min 24.0, current 24.1, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min n/a

Driver 1: standstill, SG min n/a

Driver 2: standstill, SG min n/a

Driver 3: standstill, SG min n/a

Driver 4: standstill, SG min n/a

Driver 5:

Driver 6:

Driver 7:

Driver 8:

Driver 9:

Driver 10:

Driver 11:

Date/time: 2023-08-04 10:50:05

Cache data hit count 4294967295

Slowest loop: 24.47ms; fastest: 0.18ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 3.5ms, write time 6.4ms, max retries 0

=== Move ===

DMs created 83, segments created 3, maxWait 242732ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 14, completed 14, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 14], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== Network ===

Slowest loop: 15.10ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 1 of 8

= WiFi =

Interface state: active

Module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.27

WiFi MAC address 84:0d:8e:b3:04:69

WiFi Vcc 3.40, reset reason Turned on by main processor

WiFi flash size 4194304, free heap 21304

WiFi IP address 192.168.1.53

WiFi signal strength -70dBm, mode 802.11n, reconnections 0, sleep mode modem

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled -

@Phaedrux said in Many errors during configuration with RRF tool:

Z+ should move the extruder up away from the bed.

X+ should move the extruder to the right

Y+ should move the extruder to the back of the bed, which can be confusing because it moves the bed forward. But you need to the of the motion as moving the print head, not the bed.

XY 0,0 should be the front left corner of the bed, so a Y+ movement should move the print head towards the back.Did this part make sense and match what you see?

I notice that your Y driver direction of rotation doesn't match the config from Herve, but that will depend on how the motor pairs are connected as well.

-

@Phaedrux of course.

perfectly as you describe:Z+ should move the extruder up away from the bed.

X+ should move the extruder to the right

Y+ should move the extruder to the back of the bed, which can be confusing because it moves the bed forward. But you need to the of the motion as moving the print head, not the bed.

-

@Phaedrux but I need already help to equilibrate the 2 z motors. How can I do?

-

Follow along with the guide here: https://docs.duet3d.com/en/User_manual/Connecting_hardware/Z_probe_auto_levelling

You need to use two separate drivers, one for each z motor. And ideally you'd have a Z probe.

-

@Phaedrux to use one of the solutions presented in the link you sent, I've to change the disposition of one of the two Z motors connected to driver outputs. Like one on Za driver and the other on E1 driver. Right?

I ask because, on my Duet 2, the Z driver has a dual socket wired in series for powering two z motors at once.

In the "Prerequisites" of the article you sent I read that: "only one of the ports can be used for independent motor leveling. Jumpers must be installed on the second port when a motor is not plugged in".

The question is: can I solve the problem using, for example, the last solution "Axis levelling using endstops", without changing the wiring of the drivers? Or am I obligated to change the wiring independently of the solution I choose to follow?

Please let me know as soon as possible. And if you need more details on my question just ask.

Many thanks.

-

@genioluiz7 said in Many errors during configuration with RRF tool:

Za driver and the other on E1 driver. Right?

Yes, that is correct.

@genioluiz7 said in Many errors during configuration with RRF tool:

Or am I obligated to change the wiring independently of the solution I choose to follow?

If you use the endstop method you still need each motor on it's own driver. A single driver can't control 2 connected motors differently.

-

@Phaedrux I followed the instructions and these are the results:

-

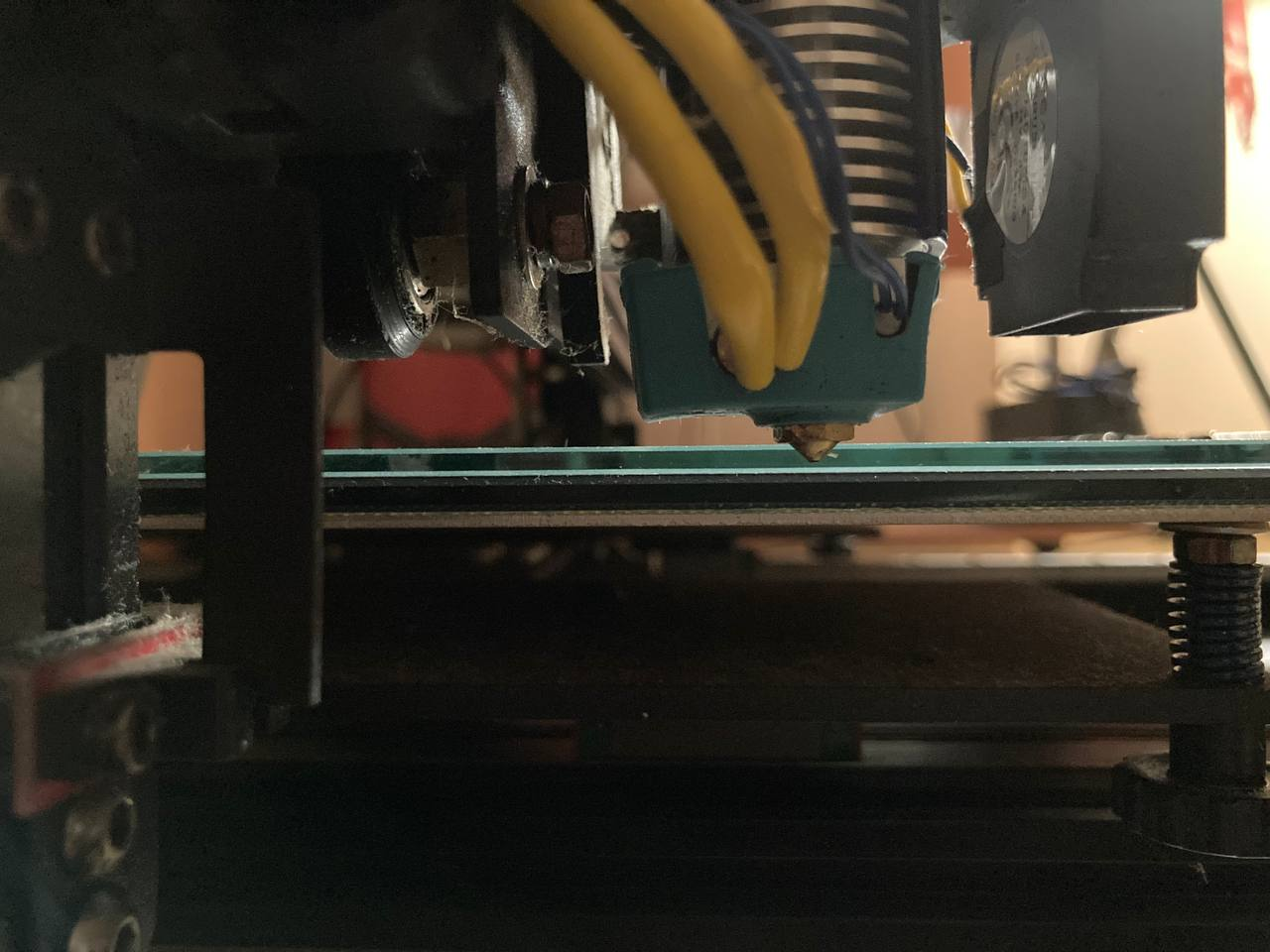

I can move the Z-axis (wired to the 2nd and the 4th drivers) together, and when I homed the z-axis the right and the left side stopped when they reached z and e1 endstop. So I think it is leveled. How can I check?

-

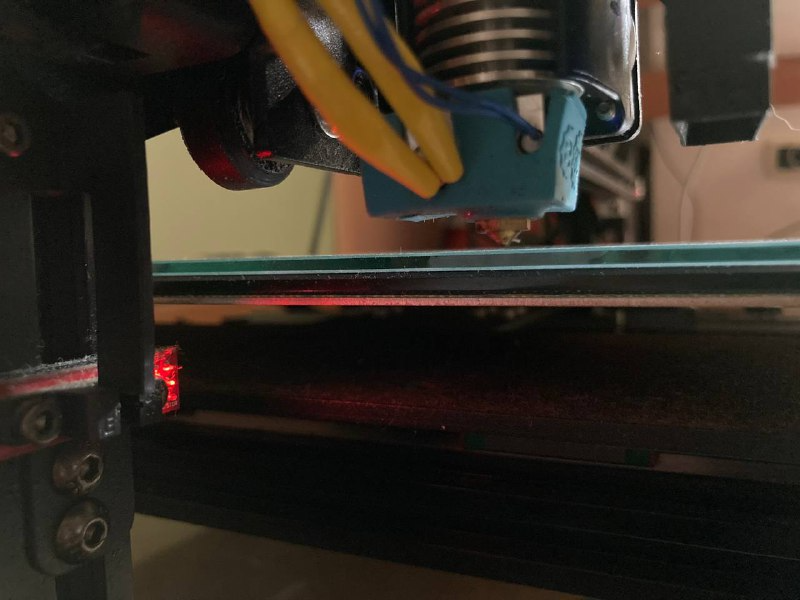

When the z-axis is homed, it's 2.5 mm under the printing surface as you can see in the pictures below. Is it a problem?

-

The homex.g and homey.g programs don't work correctly. Instead of reach each endstop, each axis moves 5 mm positively and stops, without continue to the limit. What are the problems in these .g file?

I'll repost all of them following.

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Fri Aug 04 2023 19:59:42 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-405 Y-405 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-405 Y-405 F360 ; move slowly to X and Y axis endstops once more (second pass)

G1 H1 Z-445 F360 ; move Z down stopping at the endstop

G90 ; absolute positioning

G92 Z0 ; set Z position to axis minimum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Fri Aug 04 2023 19:59:42 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-405 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 H2 X5 F6000 ; go back a few mm

G1 H1 X-405 F360 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Fri Aug 04 2023 19:59:42 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 Y-405 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 Y5 F6000 ; go back a few mm

G1 H1 Y-405 F360 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Fri Aug 04 2023 19:59:42 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 Z-445 F1800 ; move Z down until the endstop is triggered

G92 Z0 ; set Z position to axis minimum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning -

-

@genioluiz7 For X and Y, test the endstops are working correctly, and adjust the config.g code as needed. See https://docs.duet3d.com/en/How_to_guides/Commissioning#h-8-check-endstops

For Z, as you are using endstops at the minimum end of travel and not a Z , either physically move the endstops up, which would be a good idea to stop the nozzle hitting the bed, or adjust the bed down.

Ian

-

@droftarts How much do I move the endstop up? Just on the same level of the surface or a little bit upper or lower?

-

Well you want it to stop before the nozzle hits the bed. You want Z0 to be when the nozzle is touching the bed. If you have a gap, you can edit the homez.g or homeall.g to mark the Z axis at a position that takes that gap into account. So if it stops when it's 1mm above the bed surface, you can add G92 Z1 to just after your z homing move to tell the firmware that the nozzle is 1mm above the bed.

-

@genioluiz7 the endstop can’t be physically above the bed surface, or it will stop the nozzle reaching bed surface. Can your bed be adjusted? If so, I’d move the endstops to a point where the bed is halfway on its adjustment. You also need to get the endstops level, so the gantry is level, then level the bed to the nozzle.

Realistically, this isn’t a good way of homing Z; there’s too many things that could go wrong and cause a nozzle crash.. A Z probe would be a much better idea. Or set the endstops at the maximum end of the Z axis, home to there, and adjust M208 for the maximum travel. This also means recovery after a power failure mid print is easier, as you can home Z without hitting the print.

Ian

-

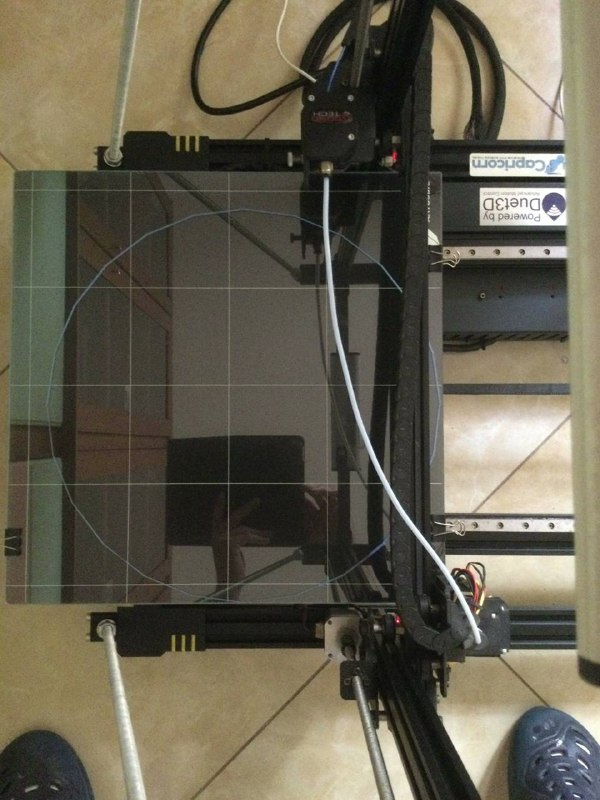

@droftarts Ok many thanks for your help. Now I've tried to launch a Chiron level test. Seem that the plate dimension or position is not understand from the start of the process. See the following picture maybe is better to show you the problem.

-

When you move the nozzle to the 0,0 XY position where does the nozzle actually end up on the bed? You likely need to adjust your M208 values such that the 0,0 point is on the front left corner of the printable area. If the endstops move the nozzle off the printable area of the bed, you can use a negative value for the M208 minima. (assuming the XY endstops are on the low end)

-

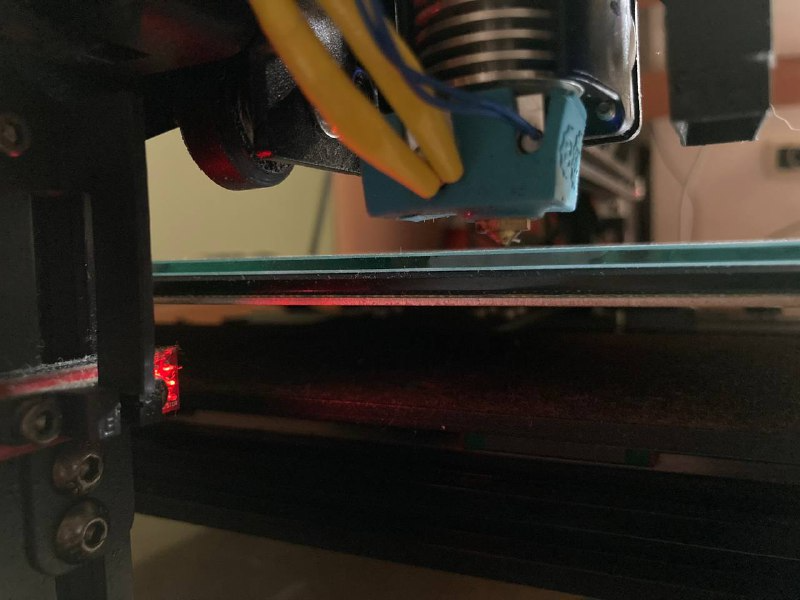

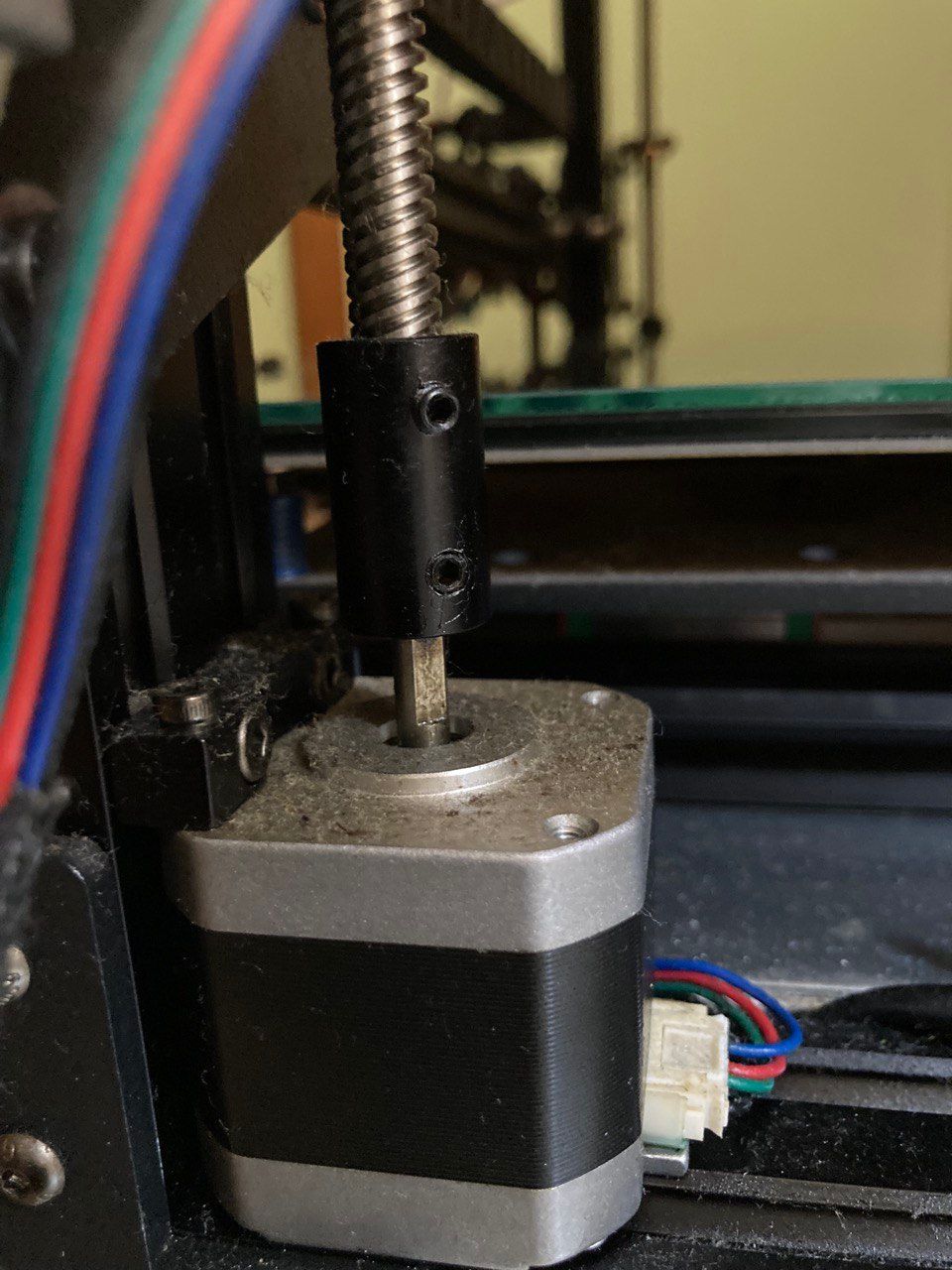

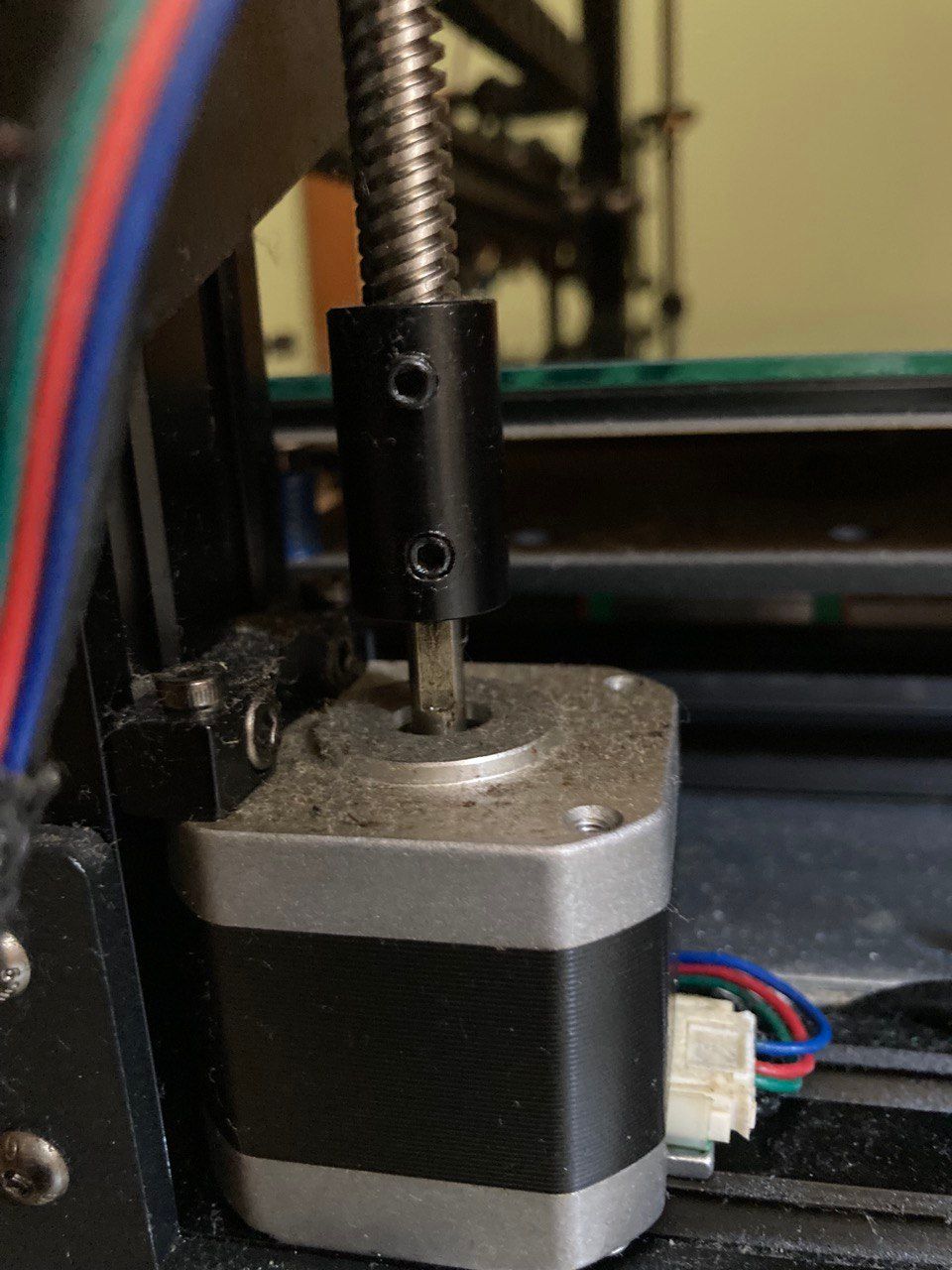

@Phaedrux many thanks for your help. I solved almost every issue. One of the remaining is the following.

When the right z motor get the position between 3.50 mm and 6 mm seems like is loosing power, and next the axis rotate backwards, while the left z motor remain stopped.

What do you think, is the problem hardware or software?- First position

- second position

- problem

- First position

-

@genioluiz7 said in Many errors during configuration with RRF tool:

z motor

Remind me how you have your z motors connected to the duet and how they are configured in config.g.

It may be that your motor current is set too low. Do you know the rated max current for those motors?