Is Input Shaper not working or what's causing ringing?

-

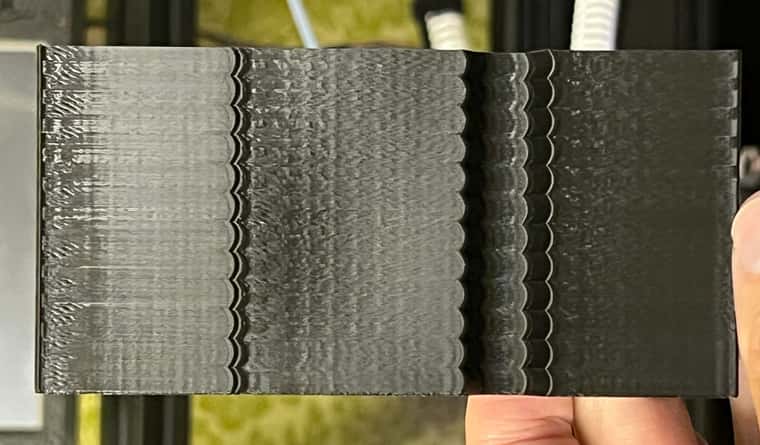

When we switched to a variant of the 2504 steppers, one of our machines was showing signs of ringing not present on others, which led us on a bit of good chase. It was never as pronounced as Op’s example though (photo below). What it turned out to be was the config on that machine still had the values for the 2004 steppers at 1750 mA.

We run the class H (High Temp) model of the 2504 steppers and set them to 2250 mA while in operation. That’s high, but they can take it without issue and our 6HC main boards are actively cooled.

image url))

image url)) -

This post is deleted! -

@oozeBot I've upped my steppers to 2A, can't see much difference in temp on the 6HC but the steppers are slowly going up, not sure how high though as I haven't printed anything big yet.

What's a safe temp reading on their outer casing?

-

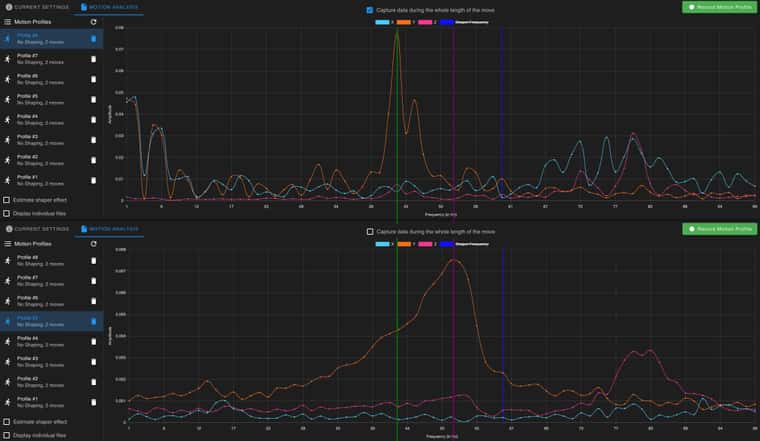

These two graphs are taken just minutes apart -- explain to me why they are so different and why the peak is not at the same frequency?

-

@Reine Just to be clear (in case others don't spot it), one set has the "capture data during entire move option" check on one but not on the other. This means you will be collecting data that includes motor vibration etc. on one but not on the other. I think the theory is that it is better to collect data after the move so that what you see is the resonance induced by the impulse but I'm no expert. The other thing to note is that the scales on the two graphs are very different (an order of magnitude), so the "peaks" in the second graph will be down in the noise of the first. Personally I don't really like the mechanism used to collect resonance data by RRF (I think the Klipper approach of basically sweeping a set of vibrations over the range, produces a stronger set of readings).

But I'm not sure the different readings you show relate to the print artefacts you are seeing. Though perhaps the fact that you get a 10x higher peak with the motors active is significant?

Looking at your earlier posts it would seem from the graphs in your first post that IS is having some impact on the resonances being shown. But perhaps those are not the cause of the artefacts you are seeing? What seems a little odd to me in the photos is that the "ringing" seems to be very spaced out (which may indicate a very low frequency) compared to what I've seen in other cases. Did you ever try estimating the frequency manually? See: https://www.klipper3d.org/Resonance_Compensation.html for a way to do this.

-

@gloomyandy I haven't used Klipper but that approach seams better to me too, an option to do X scans and average out the result and remove outliers would be a step in the right direction for the IS plugin imo.

Good point, the magnitude axis should haven an option to be fixed so it's easier to compare.

I did do the math now and came up with about 45Hz, it's lower than the graphs but not by much so that seams about right.

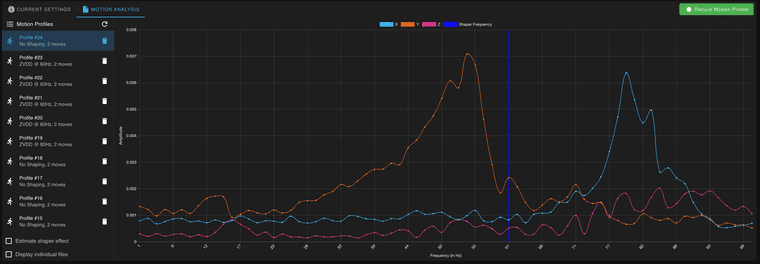

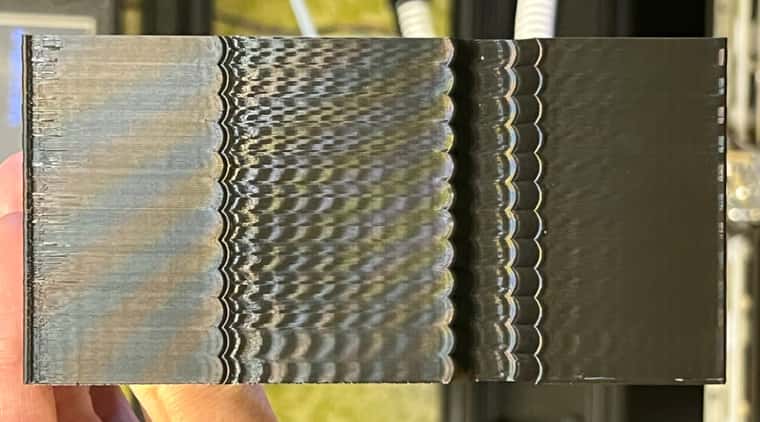

The ei3 print just finished and here is a comparsion with the zvd print I did earlier. Finally a difference, sadly still no change in the Hz range it's testing.

;AFTER_LAYER_CHANGE {if layer_z >= 0}M593 P"ei3" F35 S0.1{endif} {if layer_z >= 5}M593 P"ei3" F37 S0.1{endif} {if layer_z >= 10}M593 P"ei3" F39 S0.1{endif} {if layer_z >= 15}M593 P"ei3" F41 S0.1{endif} {if layer_z >= 20}M593 P"ei3" F43 S0.1{endif} {if layer_z >= 25}M593 P"ei3" F45 S0.1{endif} {if layer_z >= 30}M593 P"ei3" F56 S0.1{endif} {if layer_z >= 35}M593 P"ei3" F58 S0.1{endif} {if layer_z >= 40}M593 P"ei3" F60 S0.1{endif} {if layer_z >= 45}M593 P"ei3" F62 S0.1{endif} {if layer_z >= 50}M593 P"ei3" F64 S0.1{endif} {if layer_z >= 55}M593 P"ei3" F66 S0.1{endif}

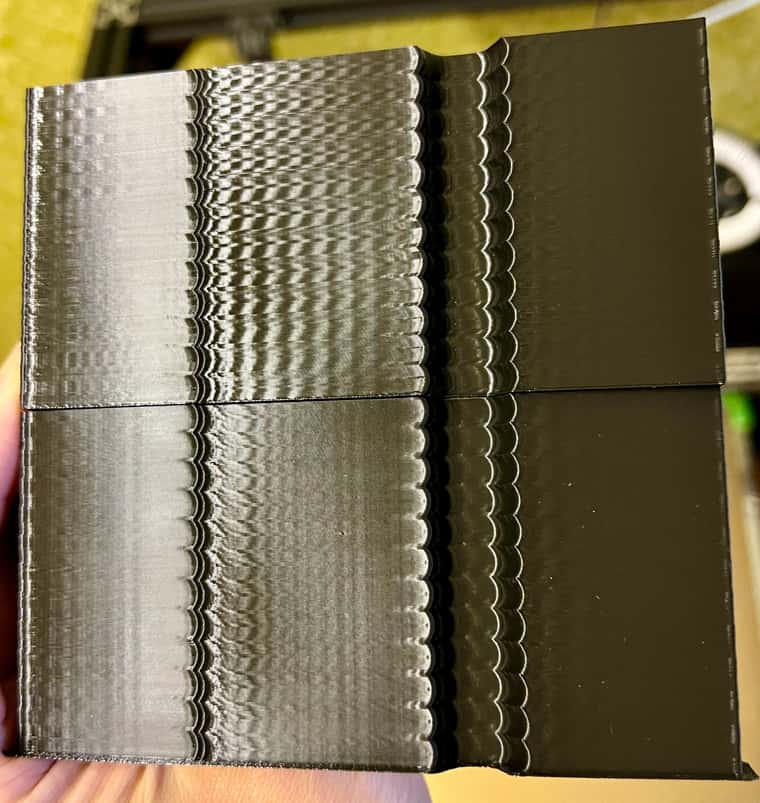

(zvd bottom, ei3 on top)Here's the gcode for that print, is there some issue in it preventing IS to update after each 5mm segment?

acceleration_test_piece_0.2mm_PLA_24m.gcode -

@Reine Is that caption correct it shows ei2 not ei3 also is it zvd on top or bottom? I'd have expected the ei3 (assuming it is that) to probably have more impact than zvd.

It would be useful to see a full print of that ringing test with all of the same settings but with IS turned off. So we can get an idea if IS is having any impact or not.

-

@gloomyandy you're correct, it was a typo. EI3 ontop and ZVD bottom.

Let me do another print with all different shapers at the same Hz. What Hz do you recommend I use?

-

@Reine I'm confused that zvd (bottom) print looks to me much better than the ei3 (top)version. Which I'm surprised at. Which looks best to you? As I said a print with no IS would be the best so we can see what the original problem was.

-

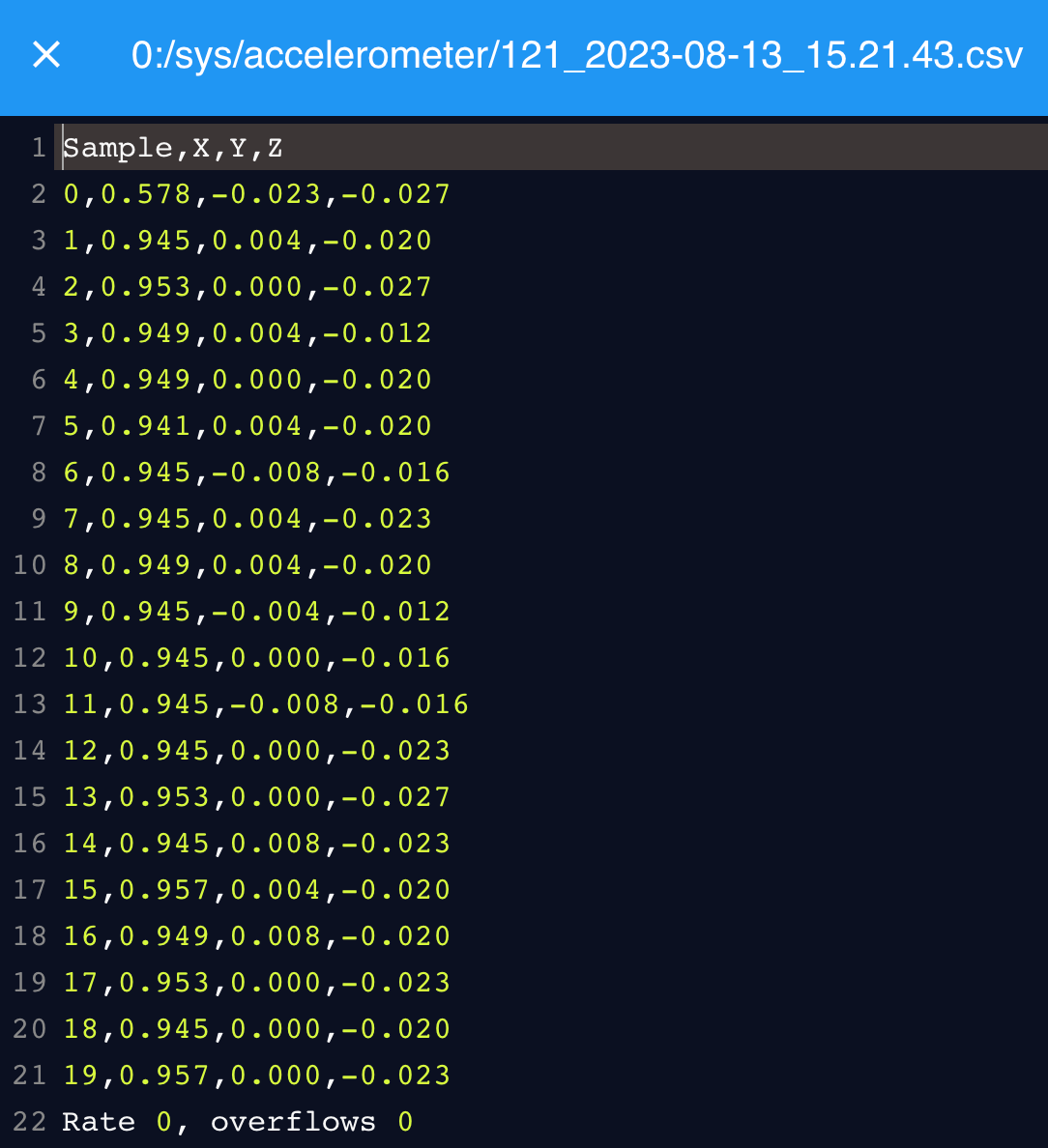

As I'm constantly getting a spike in Z and nothing in X I suspect the orientation guide might be wrong, I've been using I10 but now switched to I16 which looks more correct.

M955 P121.0 I16

-

@Reine You should be able to check the orientation (at least for Z) by checking the results from a data collection with no movement using M956 (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m956-collect-accelerometer-data-and-write-to-file) if you look at the file two of the readings (x and Y) should be close to zero and the 3rd Z should be around 1G.

-

@gloomyandy here we go, same everything except for the shaping is done like this now.

;[layer_z] {if layer_z >= 0}M593 P"none"{endif} {if layer_z >= 5}M593 P"none"{endif} {if layer_z >= 10}M593 P"mzv" F80 S0.1{endif} {if layer_z >= 15}M593 P"mzv" F67 S0.1{endif} {if layer_z >= 20}M593 P"zvd" F80 S0.1{endif} {if layer_z >= 25}M593 P"zvd" F67 S0.1{endif} {if layer_z >= 30}M593 P"zvdd" F80 S0.1{endif} {if layer_z >= 35}M593 P"zvdd" F67 S0.1{endif} {if layer_z >= 40}M593 P"zvddd" F80 S0.1{endif} {if layer_z >= 45}M593 P"zvddd" F67 S0.1{endif} {if layer_z >= 50}M593 P"ei2" F80 S0.1{endif} {if layer_z >= 55}M593 P"ei2" F67 S0.1{endif}

-

@Reine What happens if you target the frequency you previously calculated 45Hz? You might also want to try setting the damping factor to 0 (see DC42's comments here: https://forum.duet3d.com/topic/33243/which-input-shaping).

-

@gloomyandy

M956 P121.0 S20 A0

This does indeed look wrong.. I10 looks correct, but then I don't understand why the X axis is smooth and Z have a spike?

-

@Reine No idea, what does your printer look like? If you have a typical corXY type setup (with the X axis being a long beam across the printer), then I could imagine that an impulse might make it vibrate back to front and up and down but possibly not so much left to right. But I'm no expert....

-

@gloomyandy it's pretty much a stock RatRig VCore 3.1 400, with the exception for the Duet stuff and VzBot toolhead.

-

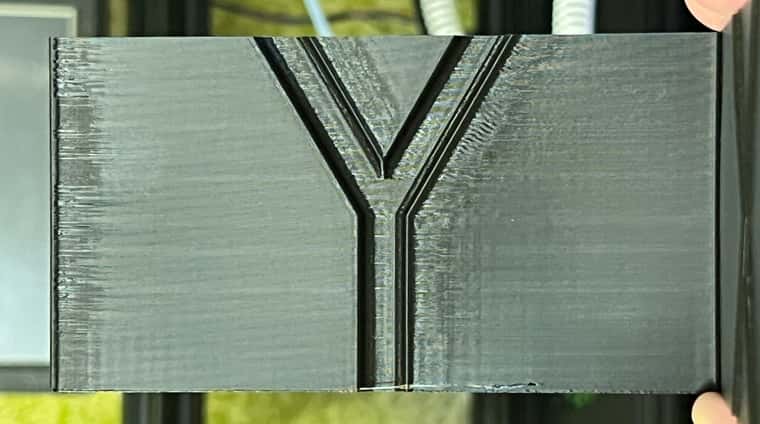

@gloomyandy I don't know but Input Shaping does not seam to work on my machine.

Video where you can see the test being printed, one axis look good the other crap. Just like all previous attempts.

Video link: https://imgur.com/a/Hzwhdz6

This time it was configures like this.

;[layer_z] {if layer_z >= 0}M593 P"none"{endif} {if layer_z >= 5}M593 P"none"{endif} {if layer_z >= 10}M593 P"mzv" F47 S0.0{endif} {if layer_z >= 15}M593 P"mzv" F47 S0.0{endif} {if layer_z >= 20}M593 P"zvd" F47 S0.0{endif} {if layer_z >= 25}M593 P"zvd" F47 S0.0{endif} {if layer_z >= 30}M593 P"zvdd" F47 S0.0{endif} {if layer_z >= 35}M593 P"zvdd" F47 S0.0{endif} {if layer_z >= 40}M593 P"zvddd" F47 S0.0{endif} {if layer_z >= 45}M593 P"zvddd" F47 S0.0{endif} {if layer_z >= 50}M593 P"ei2" F47 S0.0{endif} {if layer_z >= 55}M593 P"ei3" F47 S0.0{endif} -

@Reine I really have no idea, looking at your earlier picture you can clearly see differences between no IS and IS being on, so I'm pretty sure it is being applied. If it is not fixing the problem perhaps the artefacts you are seeing are not simple ringing, or something that IS can help to fix? Looking at this picture: https://forum.duet3d.com/assets/uploads/files/1691931423561-737eadf4-d989-4a5a-ad74-12fcef7cefa7_1_201_a.jpeg it almost seems as if the frequency of the artefact changes as you change input shaper, maybe the IS is only dealing with some of the problem?

Not sure I can help much more, here are a few random thoughts...

Looking at your printer there is a lot going on during a print. In particular you have the filament feed and what I assume is the air feed bouncing around a fair bit, plus various wires etc. which are free to move. Every one of those is able to vibrate in some way or other and may be transmitting that energy back into the print head.

Maybe the "ringing" is in effect small movements back and forth along the Y axis (which results in those artefacts which can be seen along the "front" of your prints). Your print head is quite long in the Z axis both rising above and below the linear bearing. I wonder if something is causing very small rotations of the print head around the Y axis? It may be that the bearing/mount is less able to resist motion in that direction (we are talking very small amounts), because it is narrower in that axis compared to the other one? Perhaps all of this is combining to create what you are seeing?

I'd be tempted to try disconnecting the air hose or supporting it by hand during a print to see if that changes anything and maybe the same with the filament feed.

Sorry can't be of much more help, good luck!

-

@Reine with stock vcore 3.1 400, I have only managed to eliminate the ringing with low acceleration (1000 mm/s2) and low jerk (5 mm/s), and with speed up to 100 mm/s. I don't know if IS is not working as good as klipper's, but I also have quite heavy printhead. I probably could have achieved more accel in X axis, but I just kept my maximum acceleration that has no ringing in Y axis, for both X and Y.

-

@Reine Also, I don't really know what is the best way to measure belt tension, because all apps show kind of different results. I have stayed with Gates belt app, it shows most consistency measuring the same belt 4-5 times. I would be very happy if I could compare both belts tension with IS plugin, but I haven't figured out how to perform a diagonal movement with each motor.