Input shaper causing stutters and blobs on curves RRF3.5.0-rc.1

-

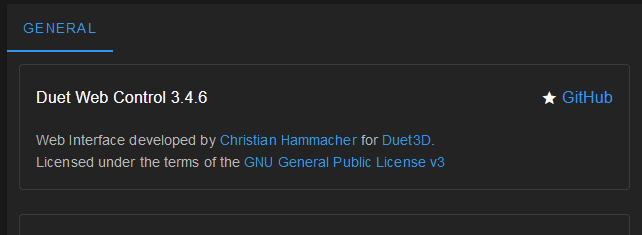

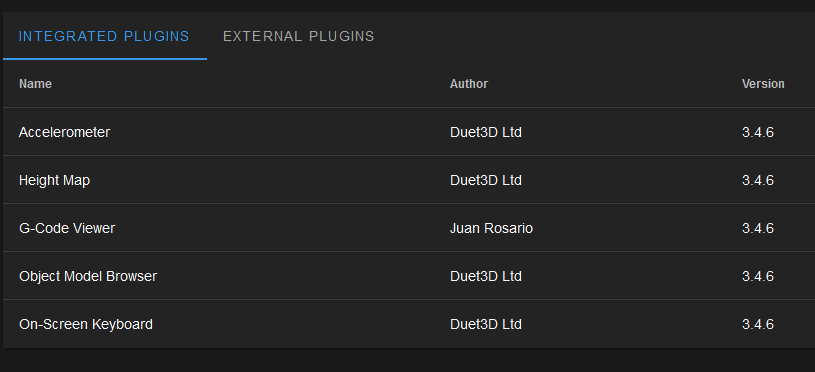

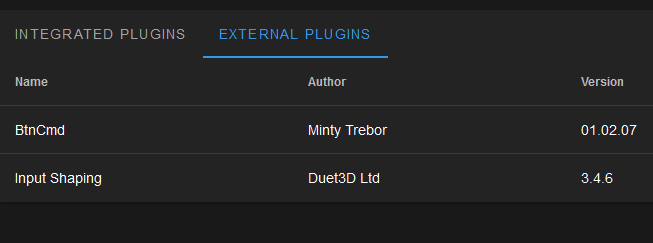

@gloomyandy As far as I can tell. Edit: Oh hang on. I just realised, does DWC not come with RRF? I think that's where I've gone wrong.

I tried increasing extruder jerk, but once I went above about 450, I started getting really bad extrusion problems. Huge holes in test prints and overall only extruding about 20% of what I should be getting. No idea what was going on with that. I'm running a Hextrudort and Goliath from VZbot, so I would expect to be able to go higher. Once I get all these problems sorted, I'll try increasing it again.

-

@Threepwood Okay now I'm back on 3.4.6 RRF, not just DWC.

-

@Threepwood None of those are showing the version number of the actual firmware. You need to look in the printer specific section of DWC or just run M122 in the console. Just to be clear DWC is not the same as RRF, they are two different components.

-

Now that I am actually back on 3.4.6. My problems seem to be gone again. Thanks @gloomyandy

Hopefully the next release of 3.5.0 will solve all these issues.

-

@Threepwood I had some issues with jerk settings today. I have increased it to 1800 and I had messed up print (I had some XY movement problems of round object perimeter and have found that it's caused by pressure advance and not high enough jerk), but the movement got even worse. Lowered to 600 and looks good for now. The only thing I am really missing right now is some explanation of correlation between acceleration and jerk settings

-

@Arminas Are you talking about extruder jerk?

I've just run a test with increasing extruder jerk values from 300 to 1400. I'm getting gaps in the print from 600 to 1400, but they don't get any worse between 600 and 1400. There was no clicking or anything from the extruder either.

This makes me think that the issue could be related to the extruder jerk allowing X and Y movement speeds/acc/jerk to increase, which is what is really causing the issues. Although, saying that, I think my acceleration and jerk are quite conservative for my Voron/VZbot setup. I am trying to print this test at 300mm/s though.

I'm not sure how to go about finding a good value for extruder jerk and acceleration. I've read people on here using 3600 extruder jerk.

Should I keep pushing it and listen for when it starts getting too clicky?

-

@Threepwood I change XY and E jerks at the same time, so not really sure what cause this issue, but my issue is related more to the XY movement.

During fast printing (200 mm/s) on rounded parts of the model the XY movement was not correct, instead of smooth circular line, it was wavy. I also noticed that lowered XY jerk leads to better input shaping results.

As for the extruder jerk, I don't really know, I just lower it together with XY and there is no issue so far. I am on RRF 3.4.6. With RRF 3.5.0 I also had blobs, so now I know that it's related to jerk settings (based on your experience), but I am not going to test it now until I find some good info about jerk/accel and speed relation.

I guess I am just trying to say that incorrect jerk settings are causing these strange things with XY and E. And it gets even more complicated with Input Shaping and Pressure Advance activated.

I have also been reading some posts where it was said to keep jerk as low as possible. I will try to do that now.

-

@Threepwood Actually, I have found good info on what exactly jerk is in a normal human language

I will keep it between the standard values 300-600 mm/s

I will keep it between the standard values 300-600 mm/s -

@Arminas said in Input shaper causing stutters and blobs on curves RRF3.5.0-rc.1:

@Threepwood I change XY and E jerks at the same time, so not really sure what cause this issue, but my issue is related more to the XY movement.

During fast printing (200 mm/s) on rounded parts of the model the XY movement was not correct, instead of smooth circular line, it was wavy. I also noticed that lowered XY jerk leads to better input shaping results.

As for the extruder jerk, I don't really know, I just lower it together with XY and there is no issue so far. I am on RRF 3.4.6. With RRF 3.5.0 I also had blobs, so now I know that it's related to jerk settings (based on your experience), but I am not going to test it now until I find some good info about jerk/accel and speed relation.

I guess I am just trying to say that incorrect jerk settings are causing these strange things with XY and E. And it gets even more complicated with Input Shaping and Pressure Advance activated.

I have also been reading some posts where it was said to keep jerk as low as possible. I will try to do that now.

There is an interaction between extruder jerk and Pressure Advance when extruder Jerk is too low. Remember that for any X Y and E move, both the axes and the extruder moves have to be synchronised, so a low extruder jerk setting will of necessity have to slow down the XY axes to keep them synchronised with the extruder. You can set extruder jerk to a "silly high" number without any adverse effects because it would only apply to extruder only moves and even then, only when there is a change of direction during that move (which never happens for extruder only moves).

-

@deckingman Any idea how to choose the most optimal jerk settings?

This line should be straight... I lowered the jerk and solved it, but now the printer does not reach max speed on curved toolpath.

-

@Arminas Try increasing the extruder jerk but keep X and Y the same. As I said before, you can set extruder jerk to "silly high" numbers - I use 3600mm/min on my machine but 900 for X and Y.

-

@deckingman This issue is related to printing speed or something else?

-

@Arminas Have you tried running ringing tower tests where you change a setting in gcode every 5mm of the print?

At what jerk setting did you find the lines straighten out? Remember that speed, jerk and acceleration can all effect ringing. Which is why I'm currently surrounded my dozens of test prints.

Despite having tuned input shaper and using the same accel and jerk settings as I used for an x carriage that was twice the weight, I'm really struggling to stop the printer from vibrating in curves. The only thing changing in this test print is print speed, from 60mm/s to 400mm/s. It seems like I can't stop the vibration above 100mm/s. Very frustrating when you see people printing with similar hardware at 400mm/s+ with far less ringing than this.

I checked the frequency of the vibration by recording the sound. It seems to be about 103hz. Which mzv @66hz should extend to, but I have a feeling this isn't related to acceleration.

No idea where to go to from here...

-

@Threepwood I had zero ringing at 3k accel, 300 mm/s jerk at 200 mm/s speed, but with such a low jerk for XY, I can not reach 200 mm/s at NOT straight lines. I have some hope that I will be able to solve this

-

I've now reduced acceleration and jerk to half what it was, and the result is exactly the same.

-

@Threepwood It might be worth trying a shaper that spans a large range and change the frequency every 5mm of the print.

If you chose ei3 (which spans about 40Hz) you should be able to change the frequency by 30Hz steps like 30, 60, 90. Hopefully it will give a clue as to what is going on and you would only have to print a 15mm high part.

-

@tas Good idea. I'll give that a go.

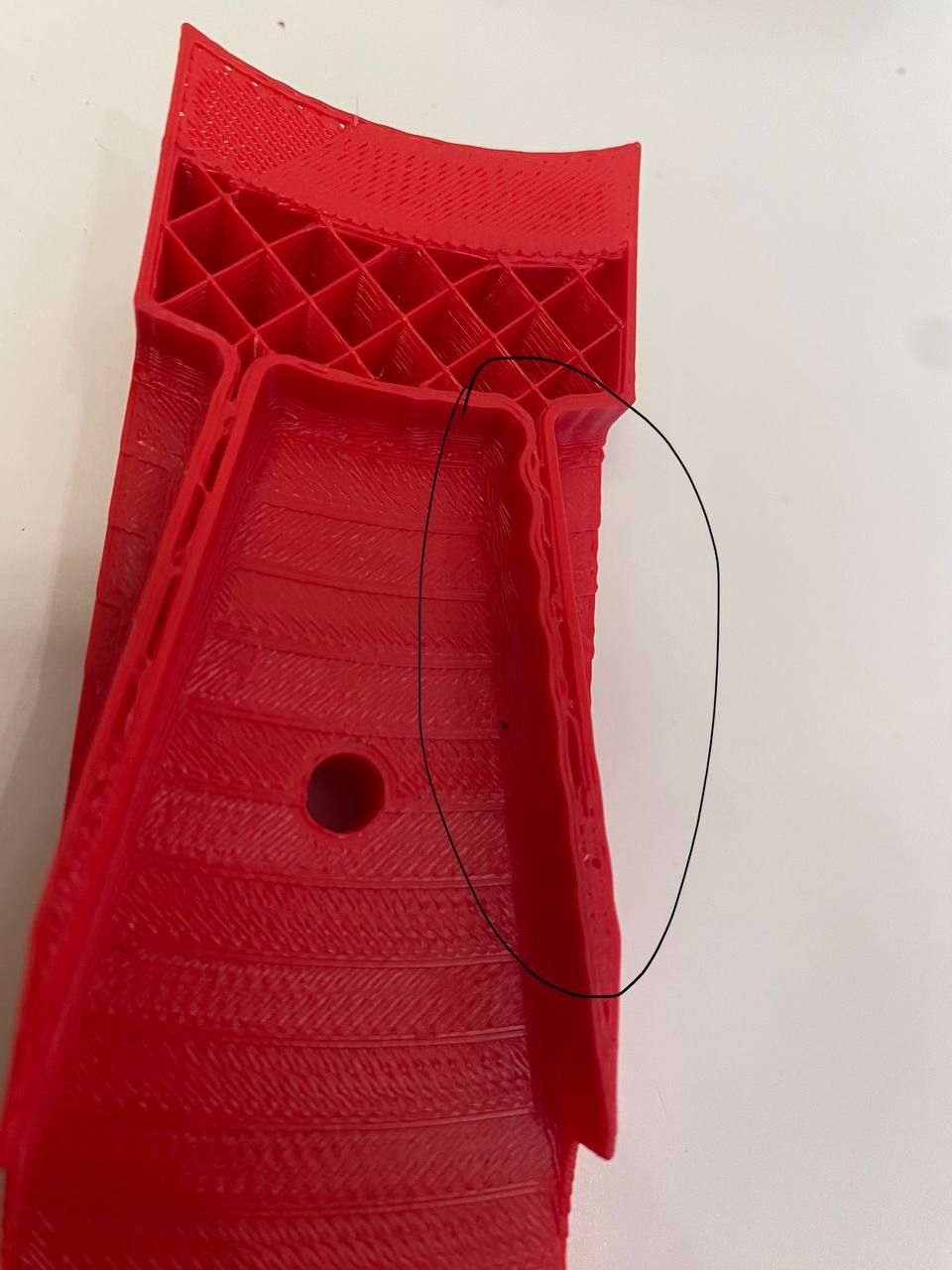

I've confirmed something I already suspected. I noticed the test print file I was trying to print had quite low refinement in the STL. I suspected the vibration could be caused by the straight sections that make up the "curve".

I replicated the problematic curve in CAD. At my normal (fairly high) refinement on the STL, the print didn't vibrate like before. I tried saving the file at lower refinements, and these are the results.

Low, medium and high refinement. on the STL.

So the problem is when the increments of an STL at printing speed match a resonant frequency in the printer.

I'll try doing some test prints with a low refinement STL to see what settings can reduce or eliminate this problem with low refinement STLs.

-

After trying MZV @66hz, ZVDDD @66, 80 and 100hz and EI3 @66 and 80hz, there is no difference in the ringing through the whole test. To the point that I can't tell where one test ends and another begins until I look at the sharp corners on the back of the print.

-

System has marked this topic as solved

-

@Threepwood So the solution is to use a high quality stl's?

-

@Arminas If the solution is high quality STLs then you also have to try out different slicer resolutions.

In PrusaSlicer it is called G-code resolution (in Print Settings>Slicing). I experimented with this and found 0.5mm was terrible, 0.1mm was ok and 0.0125mm was great. The smaller the value the bigger the g-code file but the better the resolution.

I think the idea of this feature is to reduce g-code file size to not overload the printer's brain but still provide good results. It might be worth a look. The default is 0.0125mm.

Too many variables in too many places if you ask me.