Type of wire, duet 3 to toolboard

-

Hi again.

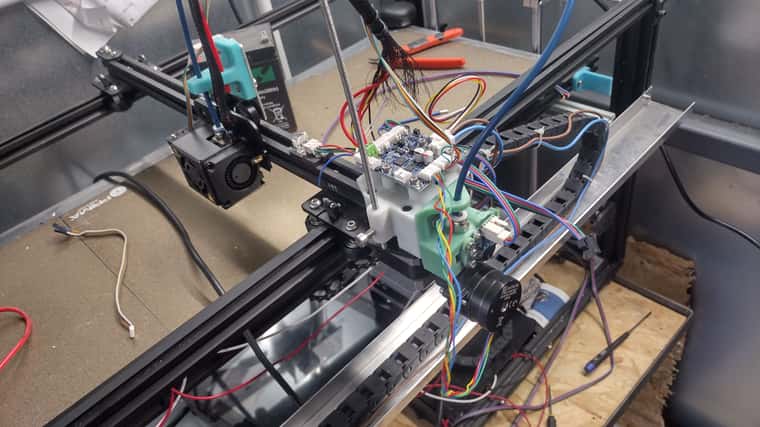

I was going to just cut a network cable and use that to go between the duet and the tool board but wanted to know if their is a better way, Starting to get white elephant vibes on this project. Realsing how much weight I'm putting into the axis movmentalso

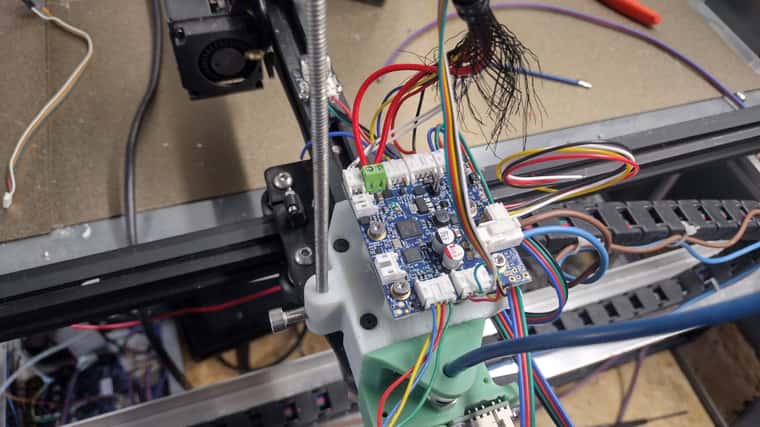

We recommend connecting the hot end metalwork to ground on the tool board via a resistor (10k to 1M Ohm), if it is not grounded through its mounting system. This will prevent the hot end building up static charge, which might otherwise occur as filament is extruded and may then flash over to the tool board thermistor input, causing damage.

Just means run a wire to the metal plate on the carriage and thrown in a resistor?Cheers Darrell

hat

hat -

Ethernet cable should work ok. Generally it's phone cable for the boards with an actual connector.

https://docs.duet3d.com/en/User_manual/Machine_configuration/CAN_connection

Yes you'd want to ground the metal work as decribed.

-

@Daz_Rich current version Duet3D tool boards already have a resistor between each of the 4 mounting holes and ground. So if you are using a version 1.2 or 1.3 tool board and it is screwed to the hot end using metal screws, no need to add extra grounding.

-

@Phaedrux said in Type of wire, duet 3 to toolboard:

it's phone cable for the boards with an actual connector.

https://docs.duet3d.com/en/User_manual/Machine_configuration/CAN_connection

Yes you'd want to ground the metal work as decribed.Magic that answered what I needed, hopefully the last part till it's reliable

Then to the upgrades 40x40 instead of 20x20