issue with 1LC+3.5.0RC2 and magnetic filament sensor V3

-

So the issue appears to be with firmware.

setup - mini5+

2x 1LC

Filament sensor V3 - light are blinking as they supposed to.

M591 D0 and D1- no data received.

Swapping to V1.7 sensor - works fine

Downgrading to 3.4.6 1LC firmware both sensors work.

I believe that V3 works with 3.5.0Beta version too.

Same issue with RC1 and RC2.

When downgrade 1LC firmware Mini5+ remained on the 3.5.0 RC2

@dc42 can you please check it? -

undefined Phaedrux moved this topic from Firmware installation 7 Jan 2024, 19:21

-

@Aurimas can you post your config.g? Did you change the config between 3.4.6 and 3.5.0-rc.2?

Ian

-

@droftarts it is nothing to do with config - it is same between the versions. operation is simple - unplug v3.0 and plug in older version and it works

but since you want a copy of the config that was uploaded multiple times here we go; Configuration file for Duet 3 Mini 5+ (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 08 2021 10:30:29 GMT+1000 (Australian Eastern Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Vega300-IDEX" ; set printer name G4 S1 ;wait for expansion boards to start ; Network ;M551 P"Vega" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet M575 P1 S1 B57600 M584 X0.2 Y0.3 Z0.0:0.1 U0.4 E121.0:20.0 ; set drive mapping M669 K1 X1:1:0:0 Y-1:1:0:0 U0:0:0:1 Z0:0:1:0 ; select CoreXY mode ; Drives M569 P0.0 S0 D3 V40 ; physical drive 0.0 goes forwards M569 P0.1 S0 D3 V40 ; physical drive 0.1 goes forwards M569 P0.2 S1 ;D3 V40 ; physical drive 0.2 goes forwards M569 P0.3 S1 ;D3 V40 ; physical drive 0.3 goes forwards M569 P0.4 S0 ;D3 V40 ; physical drive 0.4 goes forwards M569 P121.0 S0 D3 V40 M569 P20.0 S0 D3 V40 M350 X16 Y16 Z16 U16 T1 E16:16 I1 ; configure microstepping with interpolation M671 X-125:465 Y170:170 S14 M92 X80.00 Y80.00 Z2400.00 U80.00 E400.0:400.0 ; set steps per mm M566 X1200.00 Y1200.00 Z20.00 U1200 E3200.00:3200.00 ; set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y15000.00 Z280.00 U15000.00 E10200.00:10200.00 ; set maximum speeds (mm/min) M201 X5000.00 Y5000.00 Z25.00 U5000.00 E1550.00:1550.00 ; set accelerations (mm/s^2) M906 X1600 Y1600 Z850 U1200 E600:600 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S90 ; Set idle timeout ; Axis Limits M208 X-65 Y0 U0 Z-1 S1 ; set axis minima M208 X325 Y340 U390 Z420 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io3.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin M574 Y1 S1 P"!io4.in" M574 U2 S1 P"!io2.in" M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"121.^io0.in" H5 F2200 T3000 S0.25 ; set Z probe type to bltouch and the dive height + speeds G31 P300 X-30 Y5 Z2.5 ; set Z probe trigger value, offset and trigger height Increase Z number if the nozzle is too far M557 X50:330 Y25:280 S200 ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"121.temp0" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S350 M308 S2 P"20.temp0" Y"pt1000" R2200 ; configure sensor 2 as PT1000 on pin 121.io0.in M950 H2 C"20.out0" T2 ; create nozzle heater output on 122.out0 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S350 ; set temperature limit for heater 2 to 350C M308 S4 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin temp2 ;M950 H4 C"out5" T4 ; create chamber heater output on out2 and map it to sensor 4 ;M307 H4 B1 S1.00 ; enable bang-bang mode for the chamber heater and set PWM limit M141 H4 ; map chamber to heater 2 ;M143 H4 S70 ; set temperature limit for heater 2 to 280C ; Fans M950 F2 C"20.out1" Q500 ; create fan 1 on pin 121.out2 and set its frequency M106 P2 S0 ; set fan 1 value. Thermostatic control is turned on M950 F1 C"121.out1" Q500 ; create fan 3 on pin 122.out2 and set its frequency M106 P1 S0 ; set fan 3 value. Thermostatic control is turned on M950 F5 C"out5" Q500 ; create fan 1 on pin out3 and set its frequency ;M106 P5 S1 H4 T55 ; set fan 1 value. Thermostatic control is turned on M950 F4 C"20.out2" Q500 M106 P4 T45 H2 M950 F3 C"121.out2" Q500 M106 P3 T45 H1 M950 P12 C"out1" M42 P12 S1 ;turn the light on M950 F10 C"out6" Q500 ; create fan 2 on pin out5 and set its frequency M106 P10 S1 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 S"Left Extruder" D0 H1 F1 ; define tool 1 M568 P0 S0 R0 A0 M563 P1 S"Right extruder" D1 H2 X3 F2 ; define tool 2 M568 P0 S0 R0 A0 ; ''' Create a tool that prints 2 copies of the object using both carriages''' M563 P2 S"Copy 200x340" D0:1 H1:2 X0:3 F1:2 L0; tool 2 uses both extruders, hot end heaters and fans, and maps X to both X and U G10 P2 X30 Y0 U-165 S0 R0 ; set tool offsets and temperatures M567 P2 E1:1 ; set mix ratio 100% on both extruders ;''' Create a tool that prints 2 copies of the object using both carriages''' M563 P3 S"Mirror 180x340" D0:1 H1:2 X0:3 F1:2 L0; tool 2 uses both extruders, hot end heaters and fans, and maps X to both X and U G10 P3 X50 Y0 U-370 S0 R0 ; set tool offsets and temperatures M567 P3 E1:1 ; set mix ratio 100% on both extruders ; Custom settings are not defined M591 D0 P3 C"121.io1.in" S1 R10:150 L24.8 E15.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection lengt M591 D1 P3 C"20.io1.in" S1 R10:150 L24.8 E15.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length ; Miscellaneous M575 P1 S0 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory T0 ; select first tool M307 H0 R0.21 K0.586:0.000 D3.70 E1.35 S1.00 B1 -

-

@droftarts said in issue with 1LC+3.5.0RC2 and magnetic filament sensor V3:

lease bear with us while we investigate.

thanks. firmware is newest

-

@Aurimas sorry, it’s

M122 B20andM122 B121that we need. I’m interested to see what version of the boot loader your 1LC boards are on.Ian

-

@Aurimas please also send the responses to M591 D0 and M591 D1 when all boards are running 3.5.0-rc.2.

-

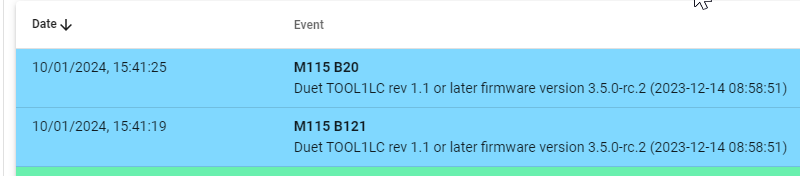

@droftarts as requested

M122 B121 Diagnostics for board 121: Duet TOOL1LC rev 1.1 or later firmware version 3.5.0-rc.2 (2023-12-14 08:58:51) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 3232, free system stack 114 words Tasks: Move(3,nWait,0.0%,135) HEAT(2,nWait,0.3%,121) CanAsync(5,nWait,0.0%,55) CanRecv(3,nWait,0.0%,79) CanClock(5,nWait,0.0%,67) ACCEL(3,nWait,0.0%,53) TMC(2,nWait,3.0%,57) MAIN(1,running,92.2%,316) IDLE(0,ready,0.0%,27) AIN(2,delaying,4.5%,122), total 100.0% Last reset 00:00:40 ago, cause: power up Last software reset data not available Driver 0: pos 0, 400.0 steps/mm, standstill, SG min 0, read errors 0, write errors 0, ifcnt 14, reads 20000, writes 14, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, segs 0, step errors 0, maxLate 0 maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00 max 0.00 Peak sync jitter -1/8, peak Rx sync delay 195, resyncs 0/0, no timer interrupt scheduled VIN voltage: min 24.1, current 24.1, max 24.1 MCU temperature: min 20.2C, current 25.2C, max 25.2C Last sensors broadcast 0x00000002 found 1 58 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 848, send timeouts 0, received 539, lost 0, errs 0, boc 0, free buffers 18, min 18, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: LIS3DH, status: 00 Inductive sensor: not found I2C bus errors 0, naks 6, contentions 0, other errors 0 === Filament sensors === Interrupt 4 to 8us, poll 8 to 825us Driver 0: pos 2160.00, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0M122 B20 Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.5.0-rc.2 (2023-12-14 08:58:51) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 3256, free system stack 114 words Tasks: Move(3,nWait,0.0%,135) HEAT(2,nWait,0.2%,125) CanAsync(5,nWait,0.0%,55) CanRecv(3,nWait,0.0%,79) CanClock(5,nWait,0.0%,67) ACCEL(3,nWait,0.0%,53) TMC(2,delaying,3.0%,57) MAIN(1,running,92.3%,316) IDLE(0,ready,0.0%,27) AIN(2,delaying,4.5%,114), total 100.0% Last reset 00:01:23 ago, cause: power up Last software reset data not available Driver 0: pos 0, 400.0 steps/mm, standstill, SG min 0, read errors 0, write errors 0, ifcnt 14, reads 41973, writes 14, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, segs 0, step errors 0, maxLate 0 maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00 max 0.00 Peak sync jitter -1/8, peak Rx sync delay 205, resyncs 0/0, no timer interrupt scheduled VIN voltage: min 24.4, current 24.4, max 24.5 MCU temperature: min 21.2C, current 27.1C, max 27.1C Last sensors broadcast 0x00000004 found 1 4 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 1744, send timeouts 0, received 1105, lost 0, errs 0, boc 0, free buffers 18, min 18, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: LIS3DH, status: 00 Inductive sensor: not found I2C bus errors 0, naks 6, contentions 0, other errors 0 === Filament sensors === Interrupt 4 to 8us, poll 6 to 568us Driver 0: pos 2160.00, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 -

Ok I have discovred something interesting.

I I boot the boards with V3 I get:Duet3D magnetic filament monitor v4 on pin 121.io1.in, enabled when SD printing, 24.80mm/rev, allow 10% to 150%, check printing moves every 15.0mm, mag 133 agc 81, no calibration dataIf I connect V1.7 that produces this:

Duet3D magnetic filament monitor v4 on pin 121.io1.in, enabled when SD printing, 24.80mm/rev, allow 10% to 150%, check printing moves every 15.0mm, mag 131 agc 80, no calibration dataIf I then disconnect V1.7 and connect V3.0 - it give the same output, i.e. it is reporting correctly.

Then I ran M122 B121 when it is not working:M122 B121 Diagnostics for board 121: Duet TOOL1LC rev 1.1 or later firmware version 3.5.0-rc.2 (2023-12-14 08:58:51) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 3232, free system stack 142 words Tasks: Move(3,nWait,0.0%,135) HEAT(2,nWait,0.3%,127) CanAsync(5,nWait,0.0%,55) CanRecv(3,nWait,0.0%,79) CanClock(5,nWait,0.0%,67) ACCEL(3,nWait,0.0%,53) TMC(2,delaying,3.0%,57) MAIN(1,running,92.2%,316) IDLE(0,ready,0.0%,27) AIN(2,delaying,4.5%,114), total 100.0% Last reset 00:01:57 ago, cause: power up Last software reset data not available Driver 0: pos 0, 400.0 steps/mm, standstill, SG min 0, read errors 0, write errors 0, ifcnt 14, reads 58735, writes 14, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, segs 0, step errors 0, maxLate 0 maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00 max 0.00 Peak sync jitter -3/8, peak Rx sync delay 207, resyncs 0/0, no timer interrupt scheduled VIN voltage: min 24.1, current 24.1, max 24.2 MCU temperature: min 34.9C, current 36.8C, max 36.8C Last sensors broadcast 0x00000002 found 1 28 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 2446, send timeouts 0, received 1550, lost 0, errs 0, boc 0, free buffers 18, min 18, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: LIS3DH, status: 00 Inductive sensor: not found I2C bus errors 0, naks 6, contentions 0, other errors 0 === Filament sensors === Interrupt 5726621 to 0us, poll 6 to 828us Driver 0: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0Then I swapped the sensors - back and forth and did M122 with V3.0 once again and now result is completely different - look at the change in the interrupt:

Diagnostics for board 121: Duet TOOL1LC rev 1.1 or later firmware version 3.5.0-rc.2 (2023-12-14 08:58:51) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 3232, free system stack 114 words Tasks: Move(3,nWait,0.0%,135) HEAT(2,nWait,0.3%,111) CanAsync(5,nWait,0.0%,55) CanRecv(3,nWait,0.0%,79) CanClock(5,nWait,0.0%,67) ACCEL(3,nWait,0.0%,53) TMC(2,delaying,3.0%,57) MAIN(1,running,92.1%,316) IDLE(0,ready,0.0%,27) AIN(2,delaying,4.5%,114), total 100.0% Last reset 00:07:18 ago, cause: power up Last software reset data not available Driver 0: pos 0, 400.0 steps/mm, standstill, SG min 0, read errors 0, write errors 0, ifcnt 14, reads 29602, writes 0, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, segs 0, step errors 0, maxLate 0 maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00 max 0.00 Peak sync jitter -4/8, peak Rx sync delay 209, resyncs 0/0, no timer interrupt scheduled VIN voltage: min 24.1, current 24.1, max 24.2 MCU temperature: min 34.9C, current 39.6C, max 39.6C Last sensors broadcast 0x00000002 found 1 126 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 6623, send timeouts 0, received 4187, lost 0, errs 0, boc 0, free buffers 18, min 18, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: LIS3DH, status: 00 Inductive sensor: not found I2C bus errors 0, naks 0, contentions 0, other errors 0 === Filament sensors === Interrupt 4 to 8us, poll 8 to 882us Driver 0: pos 2160.00, errs: frame 141 parity 0 ovrun 0 pol 4 ovdue 0So just to make sure that is clear:

Test 1- boot with V3.0 - no go. sensor is not seen by the toolboard

- with power on swap to V1.7 - it is seen and functioning

- with power on swap back to V3.0 - works fine too

- cycle power no go again

Test 2

- boot with v1.7 - sensor works fine

- swap to v3.0 with power on it works fine too

-

so I did more testing - downgraded versions and the drop out after drop out.

impossible to use.

comes up with non enough movement

somehow it started detecting the sensor from the first boot now.

works sometimes for few cm and sometimes for few meters.

trying to get report from sensor says that it was between 98% to 102%

interupts through the roof as before.

LED is blinking as it supposed to - no issues there.

unpause the print and it goes for a littlewhile with filament counter starting from zero

it is not the first setup that is doing this stupid thing.

almost had enough with the magnetic sensor. just wasting time and I believe I am not the first one -

@Aurimas please can you test with the whole system on 3.5rc3

Also please confirm that you are using the same cable with both filament monitors. and that there is nothing changing between 3.5rc3 and 3.4.6

When you say you are powering up and down to change the filament monitors, is that just the toolboard or the whole system?

-

@T3P3Tony said in issue with 1LC+3.5.0RC2 and magnetic filament sensor V3:

When you say you are powering up and down to change the filament monitors, is that just the toolboard or the whole system?

the whole system

yes - no changes in the loom or anything else