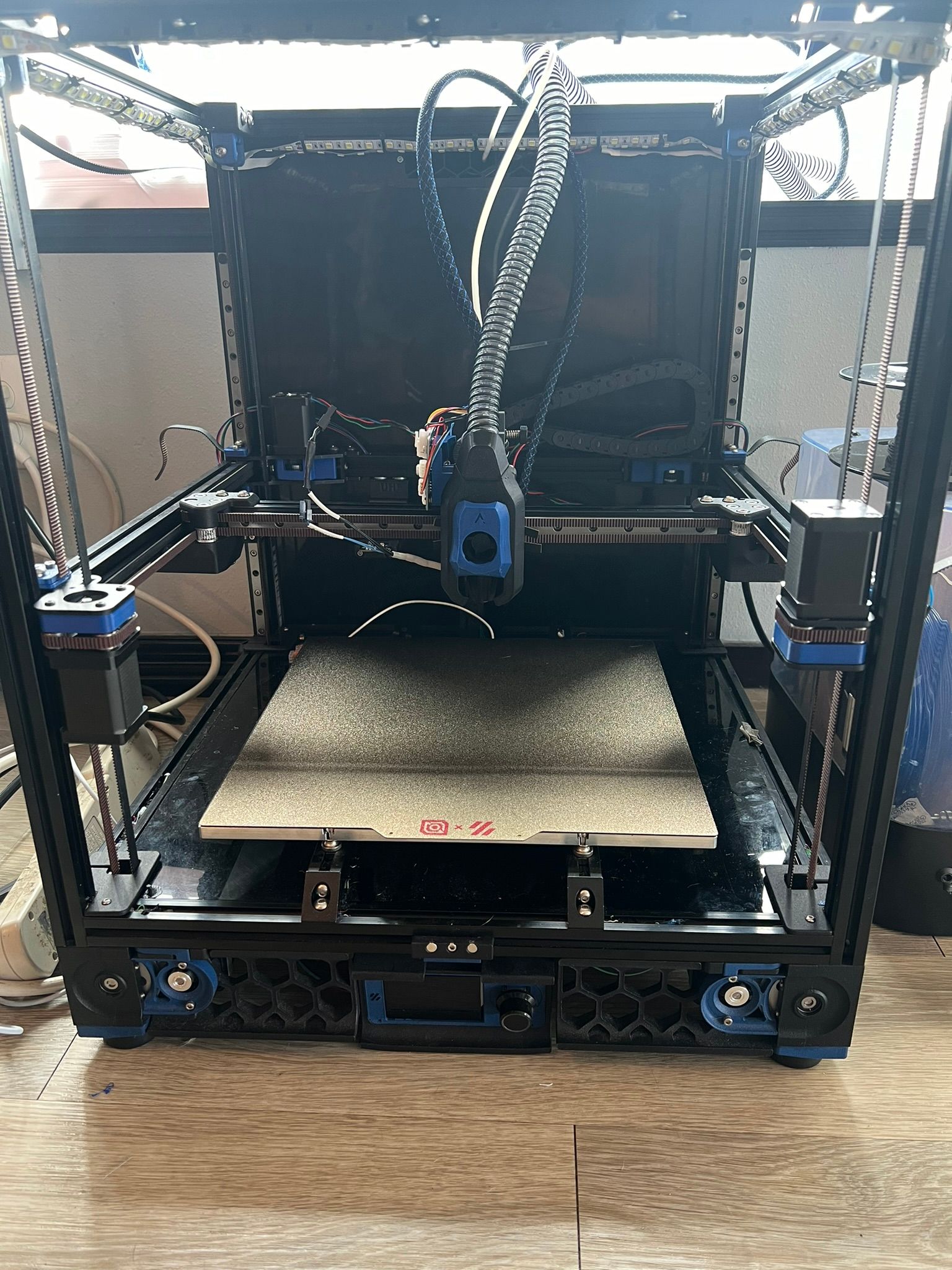

AWD Voron 2.4 - Duet3

-

I figured I'd blog my progress converting my voron 2.4 from a duet 2 system to a duet3. Along with electronics,

- I'll be going plaid with 4x nema 14 motors following aTinyShellScript's Mod: https://docs.atinyshellscript.com/v2.4/awd/#changes-needed

- Archetype - breakneck mod to a CPAP cooler for really fast printing: https://github.com/Armchair-Engineering/Archetype/tree/Experimental

- Tool board to reduce clutter - I'll design a bracket to mount the 1LC board to the breakneck board

- Rapido UHF with CHT nozzles to start pushing past 50mm^3/s

Parts are printed, everything has arrived in the mail, so now it's time to actually get started!

First thing I did was play with CAN and get that going:

Super simple. 24v to everything with the correct polarity along with the CAN cable and it all worked flawlessly. Everything's updated to the latest firmware and ready to go!

Next step:

- Covert to AWD

- Install Archetype tool head

- Rewire tool head along CPAP hose

- remove duet 2 board and install duet 3 6HC+3HC on bottom of voron.

-

-

AWD - All Wheel Drive, also known as Gone to Plaid. There's a channel in the voron discord for gone to plaid, and one in the armchair engineering group titled AWD. There could be other designs for 4x motors on vorons, but the one by aTinyShellScript is the one I found and seems to be the most active.

-

@michaelr123 the idea here is to have one motor in each corner of a corexy design?

-

Correct. more power and shorter belt paths help with improving resonance and higher print speeds. It also replaces the printed brackets on the coreXY frame with aluminum parts to improve rigidity.

-

@michaelr123 cool, i wonder what elements of that are most significant, shorter belt paths or the change in power/inertia ratio between 2xnema 14s vs 1xnema17

-

The resonance is an interesting one as from a brief look it replaces what would have been idle pulleys with second motors. If so the tendancy for the belt to flap about perpendicular to the intended travel would be largely unchanged. That said the two motors would likely add different vibration along the length of the belt reducing peaks unless they synchronised.

-

We'll see soon!

I had the day off and got a lot done on the upgrades. One thing I'm running into is needing a 5v power supply for the 5v fan recommended for breakneck: https://www.digikey.com/en/products/detail/delta-electronics/ASB02505SHA-AY6B/7491489

What would be the best way to get a 5v output from OUT_2? I see that it can be selected for either V_in or 12v, I was thinking about getting a tiny 12v to 5v buck converter. Anybody have a better idea on how to wire this up? This is what I found: https://www.amazon.com/gp/product/B0B779ZYN1/ref=ox_sc_act_title_1?smid=A3BHBZ2FB4T3LK&psc=1

I might convert over to AWD today yet, we'll see. I'm importing this fan from the UK, so it'll be a bit before I can get the upgraded toolhead put together and installed anyway.

-

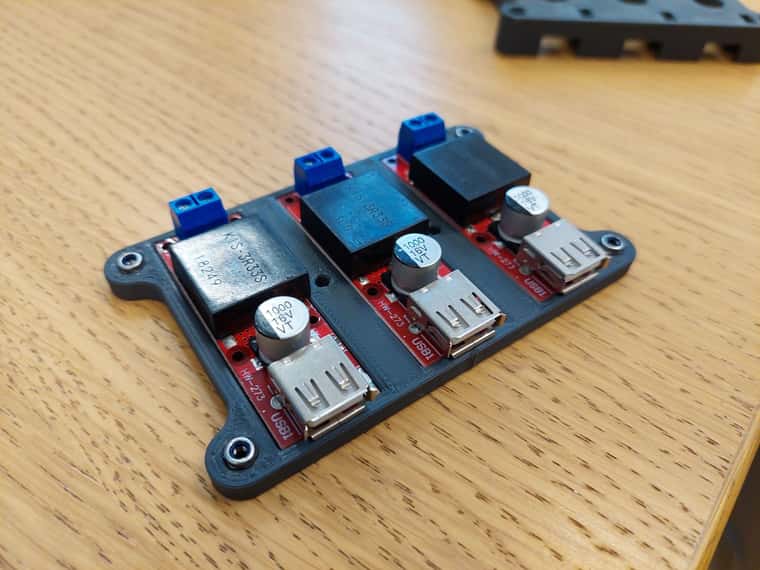

@michaelr123 if you decide to use external 5V supplies I found the following DCDC adaptors (3A 5V out) useful. Fairly sure there are options with a screw terminal instead of the USB socket, but easy enough to either remove the socket, or make up a power lead with a type A plug on one end.

-

I think the part I found is similar but miniaturized and would be soldered in. I guess my real question was to see if there was a better electrical engineering solution to this than just throwing in an a DC-DC converter. I'm also curious if the tachometer pin will work properly if I change the voltage.

-

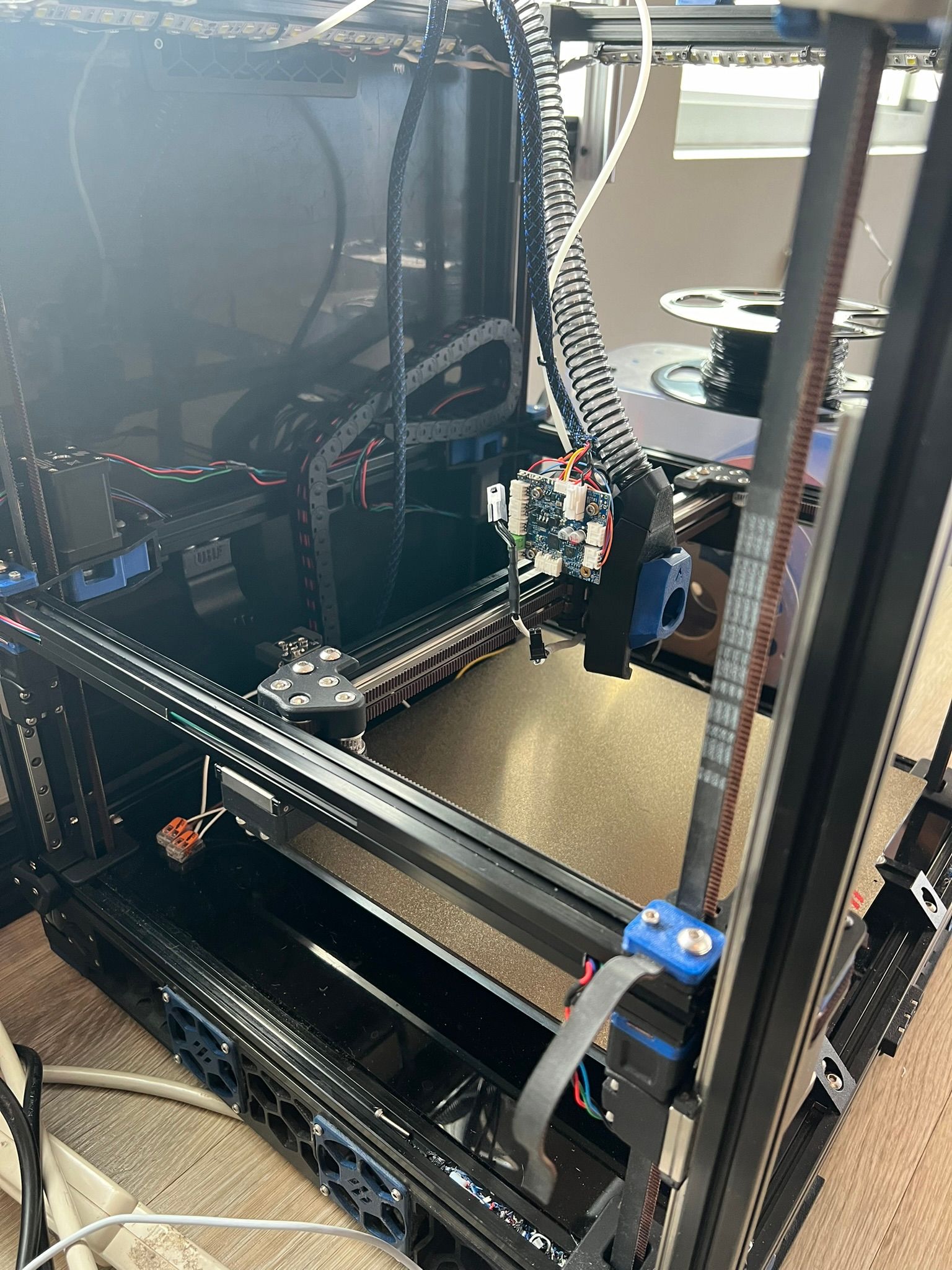

Update pictures:

- AWD installed, 4 motors are all wired up and turning the right way.

- Belts installed, archetype -breakneck tool installed. Toolboard mounted, and ready to go!

Can bus has been really easy to setup and I'm loving the simplicity in the wiring out to the tool head. I also made a decision to go for sensorless homing to completely remove the wiring harnesses from the xy axis.

Things left to do:

- Tighten and sync AWD motors.

- Finish wiring toolhead.

- Install CPAP fan, wire, program it.

- Print out frame parts for the CPAP fan because. I forgot to print those out.

- Put everything back together and sort out firmware and macros for duet 3!!

-

I'd like to revive this subject as can you share some experience?

We are building a large coreXY with 4 XY motors (nema 17 60mm)

I wonder if there are any reasons not to connect two motors to one driver?The drivers are 4.5A so there is some overhead and the setup will be 48 V. We used nema 23 with one driver on Duet 2 ethernet but only on Z axis so they have much less to do and worked for years without problems, but this time they are on XY and there will be a lot of long fast travels.

-

I've done this before for a dual drive Z axis on machines in the past without issue. You could give it a shot and report back how it went? The goals of an AWD system for a Voron is to shorten the belt paths, and to get as much power into the motion system as possible.