SKR 2 + RRF36

-

@jay_s_uk you truly are a life saver

-

@jay_s_uk I have done the following connections according to the schematics:

MOSI --- PA_7

MISO --- PA_6

SCK --- PA_5

CS --- PA_4

CAN_L --- CAN_L

CAN_H --- CAN_HAnd yet, the led on the rrf keeps on blinking rappidly, and I get "Error in start-up file macro line 24: no CAN buffer available" in console on boot-up.

config file:

; Configuration file for BTT SKR 2 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.4.0-LPC-STM32+7 on Sun Aug 20 2023 12:46:47 GMT+0300 (Eastern European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards using default driver timings M569 P1 S1 ; physical drive 1 goes forwards using default driver timings M569 P2 S0 ; physical drive 2 goes backwards using default driver timings M569 P3 S0 ; physical drive 3 goes backwards using default driver timings M569 P124.4 S1 ; physical drive 124.4 goes forwards using default driver timings M584 X0 Y1 Z2:3 E4 ; set drive mapping M350 Z256 E256 I0 ; configure microstepping without interpolation M350 X16 Y16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z6400.00 E415 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z1000.00 E3000.00 ; set maximum speeds (mm/min) M201 X10000.00 Y10000.00 Z300.00 E1000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X260 Y260 Z350 S0 ; set axis maxima ; Endstops M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"124.io0.out" ; create servo pin 0 for BLTouch M558 P9 H6 F250:30 T8000 C"^124.io0.in" ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-22.345 Y-6.941 Z2.436523 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bed" T0 ; create bed heater output on bed and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M307 H0 R0.320 K0.414:0.000 D1.01 E1.35 S1.00 B0 V24.6 ; set PID values for heated bed M143 H0 S130 ; set temperature limit for heater 0 to 120C M308 S1 P"124.temp0" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"124.out0" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C M307 H1 R3.201 K0.662:0.000 D9.07 E1.35 S1.00 B0 V24.0 ; set PID values for heater 1 ; Fans M950 F0 C"124.out1" Q250 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"124.out2" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S0 H1 T100 ; set fan 1 value. Thermostatic control is turned on ;M308 S2 P"e1temp" Y"thermistor" T100000 B4092 A"Bed mosfet" ; Tools M563 P0 D0 H1 F0:1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous T0 ; select first tool M572 D0 S0.085 ; pressure advance M308 S2 Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2209 on Duet M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as on-chip MCU temperature sensor M950 F2 C"fan2" Q20000 ; create fan 2 on pin fan2 and set its frequency M106 P2 H2:3 L0.15 X0.65 B0.3 T40 ; set fan 2 valueboard file:

// Board Hardware configuration file for BTT SKR 2 // generated by RepRapFirmware Configuration Tool (LPC Version) v3.4.0-LPC-STM32+7 // on Sun Aug 20 2023 12:46:47 GMT+0300 (Eastern European Summer Time) //Note: Each line should be less than 120 characters. // : Unwanted options can be commented out or set to NoPin. Lines commented out will get default values // : for pins the default is NoPin. // : Values for Arrays need to be contained within { and } // : Comments can be defined with // or # (comments are not supported inside arrays) // : Each config entry must be all on a single line. board = biquskr_2; //LED blinks to indicate Platform is spinning or other diagnostic //Comment out or set to NoPin if not wanted. leds.diagnostic = A.13; heat.tempSensePins = {bedtemp,e0temp}; //Max of 3 entries //heat.spiTempSensorCSPins = { }; //Max of 2 entries //Config for SKR v2.0 board = biquskr_2 //WiFi pins 8266wifi.espDataReadyPin = PB_10 8266wifi.TfrReadyPin = PB_11 8266wifi.espResetPin = PC_14 //both RX/TX Settings 8266wifi.serialRxTxPins = { PD_9, PD_8 } serial.aux.rxTxPins = { PA_10, PA_9 } heat.tempSensePins = { PD_7, PB_3, PB_4 } //leds.diagnostic = PA_04 //TMC Smart Drivers stepper.numSmartDrivers = 5; //CAN-FD Interface can.csPin = PA_4 can.spiChannel = 0Is there again something else that I'm missing?

-

@justGuner Post the output from M122, M122 P200 and a picture showing how you have the two boards connected.

-

@gloomyandy

M122 output:=== Diagnostics === RepRapFirmware for STM32F4 based Boards (biquskr_2) version 3.5.0-rc.1+102 (2023-09-05 23:19:17) running on STM32F4 (standalone mode) Board ID: A1083-0D0JA-DDPV0-7L182-YB2T9-40000 Used output buffers: 2 of 40 (15 max) Error in macro line 24 while starting up: no CAN buffer available === RTOS === Static ram: 19704 Dynamic ram: 88780 of which 176 recycled Never used RAM 21384, free system stack 157 words CCMRam static ram: 24276 dynamic ram: 33204 free ram 8052 Tasks: NETWORK(2,nWait,10.5%,243) HEAT(3,nWait,0.0%,357) Move(4,nWait,0.0%,359) TMC22xx(4,nWait,1.7%,146) FSWRITE(2,nWait,0.0%,566) MAIN(1,running,86.4%,563) IDLE(0,ready,1.4%,29), total 100.0% Owned mutexes: WiFi(NETWORK) BITIO(TMC22xx) === Platform === Last reset 00:00:57 ago, cause: power on/off Last software reset time unknown, reason: HeatTaskStuck, Gcodes spinning, available RAM 21384, slot 0 Software reset code 0x0143 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0043380f BFAR 0xe000ed38 SP 0x100005ac Task NETW Freestk 4294963012 ok Stack: ffffffed 00000000 00000000 00000000 00000000 00000000 00000000 00000000 422a2cfb 422a2cfb 422a2cfb 3edcf724 3331bb4c 41b80000 3e178897 3e1cd04f 3d8c2228 3e3a33ff 42154970 40533333 3e960961 3b800000 48737398 00000000 60000010 3e3a33ff e000e000 Error status: 0x00 MCU temperature: min 34.7, current 40.2, max 43.4 Supply voltage: min 24.0, current 24.0, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/2, heap memory allocated/used/recyclable 2048/36/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill 2209, SG min 0, reads 4735, writes 11 Driver 1: standstill 2209, SG min 0, reads 4735, writes 11 Driver 2: standstill 2209, SG min 0, reads 4735, writes 11 Driver 3: standstill 2209, SG min 0, reads 4734, writes 11 Driver 4: not present Driver 5: Driver 6: Driver 7: Driver 8: Driver 9: Driver 10: Driver 11: Driver 12: Driver 13: Date/time: 2024-02-24 16:03:06 Slowest loop: 7.32ms; fastest: 0.11ms === Storage === Free file entries: 20 SD card 0 detected SD card longest read time 1.5ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0004003 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Disabled Longest wait 0ms for reply type 0, peak Tx sync delay 0 free buffers 0 (min 0), ts 0/0/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 24.85ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) HTTP sessions: 1 of 8 Uploads/Errors: 0/0 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Bad header: 0/0 Firmware version 1.27-04S32-D MAC address 68:58:11:44:3b:b0 Module reset reason: Turned on by main processor, Vcc 0.00, flash size 4194304, free heap 144312 WiFi IP address 192.168.1.9 Signal strength -50dBm, channel 9, mode 802.11n, reconnections 0 Clock register 00002003 Socket states: 0 0 0 0 0 0 0 0M122 P200 output:

=== Diagnostics === RepRapFirmware for STM32F4 based Boards (biquskr_2) version 3.5.0-rc.1+102 running on STM32F4 at 168Mhz Bootloader: Unknown == Supported boards == Board 0.0: generic iomode 254 Signatures: Board 1.0: biquskrpro_1.1 iomode 0 Signatures: 0x768a39d6 0x50da391 0xa79a1917 Board 2.0: biqugtr_1.0 iomode 1 Signatures: 0x94a2cc03 Board 3.0: fly_e3_pro iomode 2 Signatures: 0xd0c680ae Board 4.0: fly_e3_prov3 iomode 2 Signatures: 0xd0c680ae Board 5.0: fly_f407zg iomode 2 Signatures: 0x8a5f5551 0xd0c680ae Board 6.0: fly_e3 iomode 2 Signatures: 0xd0c680ae 0xfd2146b0 Board 7.0: fly_e3_v2 iomode 2 Signatures: 0xd0c680ae Board 8.0: fly_cdyv2 iomode 2 Signatures: 0x8a5f5551 0xd0c680ae Board 8.1: fly_cdyv3 iomode 2 Signatures: 0x8a5f5551 0xd0c680ae Board 9.0: fly_super8 iomode 2 Signatures: 0x8a5f5551 0xd0c680ae Board 10.0: biquskr_rrf_e3_1.1 iomode 2 Signatures: 0x94a2cc03 0xb173b733 Board 11.0: biquskr_2 iomode 2 Signatures: 0xb75b00a7 0x35f4602c Board 12.0: biqoctopus_1.1 iomode 2 Signatures: 0x5e29d842 Board 12.1: biquoctopus_1.1 iomode 2 Signatures: 0x5e29d842 Board 13.0: biqoctopuspro_1.0 iomode 2 Signatures: 0x5e29d842 Board 13.1: biquoctopuspro_1.0 iomode 2 Signatures: 0x5e29d842 Board 14.0: biquoctopus_x7 iomode 2 Signatures: 0x5e29d842 Board 14.1: troodon_v2 iomode 2 Signatures: 0x5e29d842 Board 15.0: fysetc_spider iomode 1 Signatures: 0x8479e19e Board 16.0: fysetc_spider_king407 iomode 1 Signatures: 0xb86f16db == Configurable Board.txt Settings == board = biquskr_2 Signature 0x35f4602c leds.diagnostic = A.13 leds.diagnosticOn = true leds.activity = NoPin leds.activityOn = true pins.SetHigh = {NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin} pins.SetLow = {NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin} stepper.powerEnablePin = C.13 stepper.enablePins = {E.3, D.6, D.1, C.7, D.13, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin} stepper.stepPins = {E.2, D.5, A.15, D.15, D.11, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin} stepper.directionPins = {E.1, D.4, A.8, D.14, D.10, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin} stepper.digipotFactor = 0.00 stepper.TmcUartPins = {E.0, D.3, D.0, C.6, D.12, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin} stepper.DriverType = {tmcuartauto, tmcuartauto, tmcuartauto, tmcuartauto, tmcuartauto, stepdir, stepdir, stepdir, stepdir, stepdir, stepdir, stepdir, stepdir, stepdir} stepper.numSmartDrivers = 5 stepper.num5160Drivers = 0 stepper.spiChannel = 255 stepper.csDelay = 0 stepper.TmcDiagPins = {NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin} heat.tempSensePins = {D.7, B.3, B.4, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin} heat.spiTempSensorCSPins = {NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin, NoPin} heat.spiTempSensorChannel = 255 heat.thermistorSeriesResistor = 4700.00 atx.powerPin = NoPin atx.powerPinInverted = false atx.initialPowerOn = true sdCard.internal.spiFrequencyHz = 25000000 sdCard.external.csPin = NoPin sdCard.external.cardDetectPin = NoPin sdCard.external.spiFrequencyHz = 4000000 sdCard.external.spiChannel = 255 lcd.lcdCSPin = NoPin lcd.lcdBeepPin = NoPin lcd.encoderPinA = NoPin lcd.encoderPinB = NoPin lcd.encoderPinSw = NoPin lcd.lcdDCPin = NoPin lcd.panelButtonPin = NoPin lcd.spiChannel = 255 SPI0.pins = {A.5, A.6, A.7} SPI1.pins = {B.13, B.14, B.15} SPI2.pins = {NoPin, NoPin, NoPin} SPI3.pins = {E.15, A.14, E.14} SPI4.pins = {C.5, B.1, B.0} SPI5.pins = {E.10, NoPin, B.1} 8266wifi.espDataReadyPin = B.10 8266wifi.lpcTfrReadyPin = B.11 8266wifi.TfrReadyPin = B.11 8266wifi.espResetPin = C.14 8266wifi.csPin = B.12 8266wifi.serialRxTxPins = {D.9, D.8} 8266wifi.spiChannel = 1 8266wifi.clockReg = 0 serial.aux.rxTxPins = {A.10, A.9} led.neopixelPin = NoPin power.VInDetectPin = NoPin power.voltage = 24 accelerometer.spiChannel = 255 can.spiChannel = 0 can.csPin = A.4 can.spiFrequencyHz = 15000000 == Defined Pins == bedtemp,tb = A.1 e0temp,th0 = A.2 e1temp,th1 = A.3 xstop = C.1 ystop = C.3 zstop = C.0 e0stop,e0det = C.2 e1stop,e1det = A.0 servo0 = E.5 probe = E.4 bed,hbed = D.7 e0heat,heat0 = B.3 e1heat,heat1 = B.4 fan0,fan = B.7 fan1 = B.6 fan2 = B.5 LCDD7 = E.13 LCDD5 = E.11 LCDRS = E.9 BEEP = C.5 BTNENC = B.0 LCDD4 = E.10 LCDD6 = E.12 LCDEN = B.1 LCDCD = C.4 BTNEN2 = B.2 BTNEN1 = E.7 LCDMISO = A.6 LCDSCK = A.5 LCDSS = A.4 LCDMOSI = A.7 Neopixel = E.6 TX1,tfttx = A.9 RX1,tftrx = A.10 XCS = E.0 YCS = D.3 ZCS = D.0 E0CS = C.6 E1CS = D.12 MISO = A.14 MOSI = E.14 SCK = E.15 SCL1 = B.8 SDA1 = B.9 PSON = E.8 PWRDET = C.15 LED,status = A.13 SP = C.13 == Hardware Serial == AUX Serial: UART 1 WIFI Serial: UART 3 == PWM == 0: Pin D.7 freq 0 value 0.000000 1: Pin B.5 freq 20000 value 0.650000 Tim 3 chan 2 2: 3: 4: 5: 6: 7: 8: 9: 10: 11: 12: 13: 14: 15: == Attached interrupt pins == 0: 1: 2: 3: 4: 5: 6: 7: 8: 9: 10: B.10 11: 12: B.12 13: 14: 15: == MCU == AdcBits = 14 TS_CAL1 (30C) = 931 TS_CAL2 (110C) = 1204 V_REFINCAL (30C 3.3V) = 1495 V_REFINT raw 5994 V_REF 3.293391 T_MCU raw 3884 T_MCU cal 41.721611 T_MCU calc 33.939026 T_MCU raw (corrected) 3876 T_MCU cal (corrected) 41.151772 T_MCU calc (corrected) 33.312321 Device Id 419 Revison Id 2003 CPUId r0p1 == RAM == RAM start 0x20000000 end 0x2001fffc CCMRAM start 0x10000000 end 0x1000fffc == USB == Read overrun 0pictures of the wiring:

keeps on giving request entity too large errors -

@justGuner Upload the pictures to a file sharing site and share a link.

-

-

@justGuner That looks ok to me. But your CAN-FD module is not being detected. Things you could try....

- It looks like the dfd module may expect an extra ground pin (pin 8 on the dfd connector, basically the pin at the opposite end to your current VCC connection. I'm not sure if it is needed, but it would normally be connected. Make sure you check the schematic before adding that wire though.

- You could try lowering the SPI frequency used to talk to the DFD. try adding:

can.spiFrequencyHz = 10000000To your board.txt file. If that is still not working try:

can.spiFrequencyHz = 5000000Other than that I'm out of ideas other than checking the actual wiring and that the pins actually go where they look like they are going.

-

@gloomyandy The other thing you could try is to connect the power for the DFD directly to the 12/24V supply. The SKR2 has a rather wacky power circuit for the drivers that may mean power for the DFD is being delayed, and it could be that the detection code has run before the DFD has settled down.

-

@gloomyandy I have connected the dfd directly to the 24v supply, and immediately began to experience mainboard reset loops upon power-up. I've removed the gnd wire, and now everything powers up as before, but there is stil no can comunication (I did try the above mentioned frequencies).

I am reaching the point where it might not be worth it to try and make this work and just buy the EFD and wait 2 weeks.

-

To add salt to the injury, I thought that maybe I needed to connect the additional int0 and int1 pins. That didn't deliver the expected outcome... (I fried the DFD, hopefully nothing else)

And so, I will post an update on the situation after receiving the EFD in I'm guessing about 2 weeks.

Finally, a little suggestion: you might want to add the reason for why it is recommended to go with the EFD on the teamgloomy website. Not just for the skr2, but for other boards as well.

-

@justGuner A quick follow up. I've just tested a EFD with an SKR2 and RRF 3.5, seems to be working fine. Jay has also updated the documentation to say that only the EFD will work on those boards for which this is the case.

-

After recieving the EFD, I can confirm that I have a connection between the skr and the toolboard. However, upon boot, I receive "invalid Z probe index" errors, and an incompatible software warning.

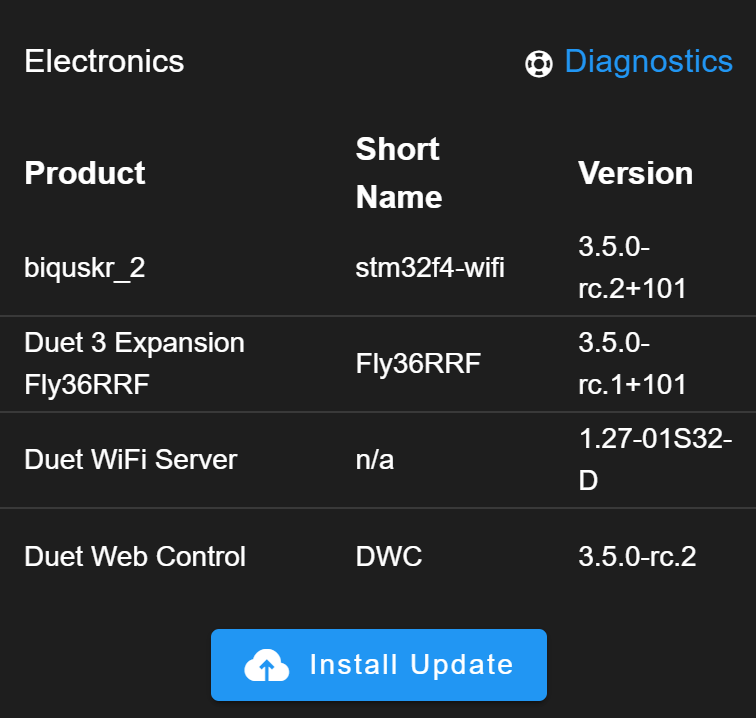

curent software versions:

I also tried with rc.3; same outcome

Here is the updated config :

; Configuration file for BTT SKR 2 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.4.0-LPC-STM32+7 on Sun Aug 20 2023 12:46:47 GMT+0300 (Eastern European Summer Time) ; General preferences G4 S2 ; wait 2 seconds G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards using default driver timings M569 P1 S1 ; physical drive 1 goes forwards using default driver timings M569 P2 S0 ; physical drive 2 goes backwards using default driver timings M569 P3 S0 ; physical drive 3 goes backwards using default driver timings M569 P124.0 S1 ; physical drive 124.4 goes forwards using default driver timings M584 X0 Y1 Z2:3 E124.0 ; set drive mapping M350 Z256 E256 I0 ; configure microstepping without interpolation M350 X16 Y16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z6400.00 E415 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z1000.00 E3000.00 ; set maximum speeds (mm/min) M201 X10000.00 Y10000.00 Z300.00 E1000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X260 Y260 Z350 S0 ; set axis maxima ; Endstops M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"124.io0.out" ; create servo pin 0 for BLTouch M558 P9 H6 F250:30 T8000 C"124.io0.in" ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-22.345 Y-6.941 Z2.436523 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bed" T0 ; create bed heater output on bed and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M307 H0 R0.320 K0.414:0.000 D1.01 E1.35 S1.00 B0 V24.6 ; set PID values for heated bed M143 H0 S130 ; set temperature limit for heater 0 to 120C M308 S1 P"124.temp0" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"124.out0" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C M307 H1 R3.201 K0.662:0.000 D9.07 E1.35 S1.00 B0 V24.0 ; set PID values for heater 1 ; Fans M950 F0 C"124.out1" Q250 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"124.out2" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S0 H1 T100 ; set fan 1 value. Thermostatic control is turned on ;M308 S2 P"e1temp" Y"thermistor" T100000 B4092 A"Bed mosfet" ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous T0 ; select first tool ;M955 P0 C"PE_10+PE_9" I20 M572 D0 S0.085 M912 P0 S-8.9 ;M593 P"zvddd" F44.8 ; use ZVDDD input shaping to cancel ringing at 46.1Hz M308 S2 Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as on-chip MCU temperature sensor M950 F2 C"fan2" Q20000 ; create fan 2 on pin fan2 and set its frequency M106 P2 H2:3 L0.15 X0.65 B0.3 T40 ; set fan 2 value -

@justGuner You need to use the same version for all of the components, your screen shot shows a mixture of rc.1 and rc.2. If you think you have the correct versions installed run M122 and M122 B124 and post the output here.

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

You also have the above in your config. See the following notes for option S2:

The S2 option of M574 is intended for use only when axes other than Z are using the Z probe for homing. The only printers known that do this using Duet electronics are the RepRapPro Ormerod, Huxley Duo, and Mendel Tricolour machines. When using the Z probe to home Z, M574 Z has no bearing on the probe setup or usage. A Z probe and a Z endstop can both be configured at the same time. G30 calling the probe setup with M558, and G1 H1 Z moves calling the endstop configured with M574 Z.

That may be generating the probe error as at that point in the config, you have not defined a probe. Either way you almost certainly do not need that setting and should probably delete it.

-

@gloomyandy I updated every component to rc.3 and now everything works as it should. Originally I thought that the latest version for the rrf36 was rc.1; apparently I just wasn't patient enough for it to update over usb and it would boot up with the old one.

Thanks for the help.

-

@justGuner Once a version of RRF is installed on the toolboard you should be able to update via CAN-FD no need to do it via USB.

-

@gloomyandy good to know