Troubleshooting print quality issue - frosty effect

-

Hi everyone,

Sorry i didn't really know how to phrase the topic.

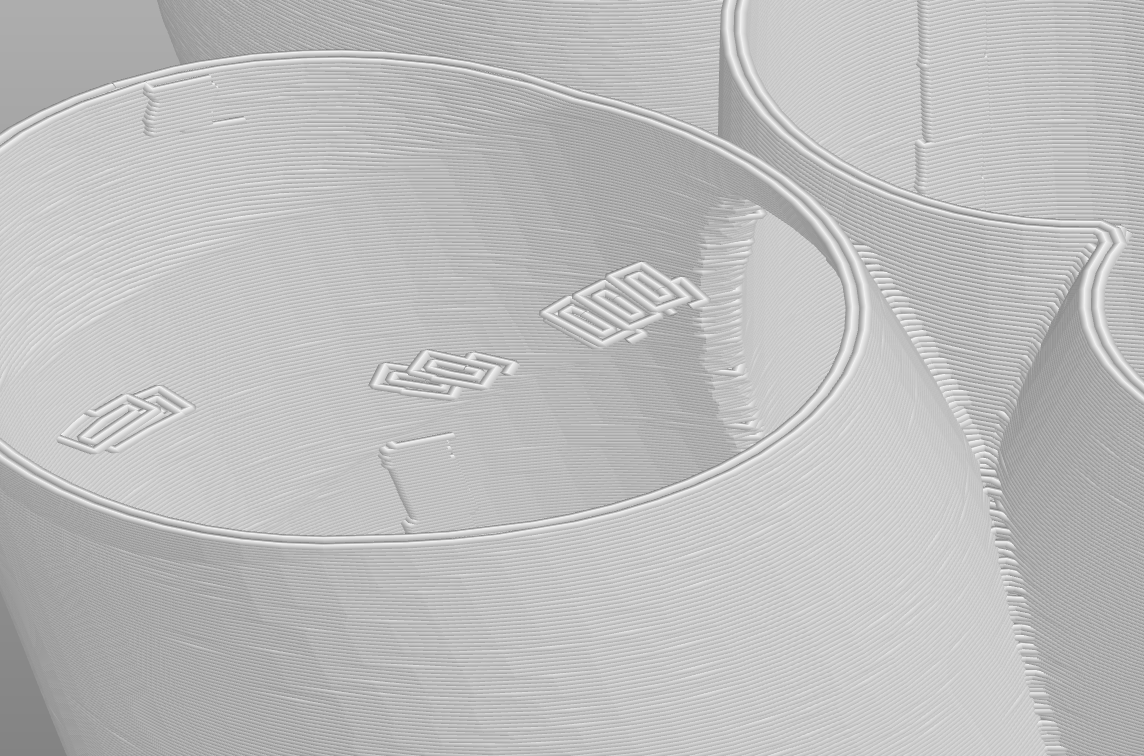

I'm having an issue with a long print where small circular portions of the tree support printed with transparent pla out of a .4mm nozzle look frosty. It looks like the movement and/or the extrusion are jagged. Maybe with some underextrusion.

Machine is a custom build with bmgx2 extruder and chimera+ dual hotend system. I tried setting different PA values, not sure it made a huge difference. For now they sit at .025 for both extruders. Other extruder has .2mm nozzle. Although both are direct drive, there is a very long ptfe tube routing the filament from the dryer to the filament monitors attached to the frame, then to the extruders. Nozzles are both hardened steel from brozzle (i like the reliability of those). I suspect PA could be the issue and the solution but am all ears to any other possibilities.

Attached are pictures, actually even the larger parts don't look that smooth, but as they don't fall apart I didn't notice that much.Thaznk you all in advance , best

-

It might make sense to run some simpler tests - such as one of the many test objects and look at cooling, temperature for that filament along with extrusion factor.

-

@T3P3Tony thank you , i have tested many temperature settings and did a few temp towers, I think this at least is on point. What other basic tests do you suggest i should run ?

-

@modl well if the temp towers, retraction amounts and PA tests all look good then it's more of a puzzle why the small features on the support are not great.

My guess was a combination of retraction amount and speed.

-

@T3P3Tony Actually i didn't test the PA setting, just used the recommended value for direct drive extruders but that is a mistake as I have this long tubing setup and specific nozzles for each extruder.

So will try testing this after everything else seems correct (iirc PA is the last thing to be set regarding extrusion?)For now retraction distance is 1mm at 30mm/s , i have set deretraction speed to 0 in prusa, maybe i should correct that actually. The retraction on tool change for the parked tool is 10mm. I don't have any "extra length on restart" or "deretraction extra length". Maybe that could help but the print is not stringy so it doesn't seem like some material is dripping during travel moves or when an extruder is on standby.

You also mentionned extrusion factor.

Should i just do single wall small diameter towers to reproduce said small features and test varying settings for all those factors ? Or are there more elaborate benchys you might think of ?

-

I don't see a reason to add extra PA, because you have PTF tube before the hotend. Unless you also have an inline extruder pushing filament into this tube...

My advice would be to purge after toolchanges. Even when you retract the parked tool 10mm, some filament remains in the nozzle and overcooks.

It's either- active cooling of the unused hotend (watercooled heaterblocks are rare) or

- setup a purge tower in Prusa-slicer (which isn't easy with different nozzle diameters)

- define your own purge corner in the toolchange macros

-

@o_lampe said in Troubleshooting print quality issue - frosty effect:

I don't see a reason to add extra PA, because you have PTF tube before the hotend. Unless you also have an inline extruder pushing filament into this tube...

My advice would be to purge after toolchanges. Even when you retract the parked tool 10mm, some filament remains in the nozzle and overcooks.

It's either- active cooling of the unused hotend (watercooled heaterblocks are rare) or

- setup a purge tower in Prusa-slicer (which isn't easy with different nozzle diameters)

- define your own purge corner in the toolchange macros

My thought process was that the added resistance of the long ptfe tubing was adding springiness to the whole extrudion process, a lag. I'll still test it anyway and not just rely on predefined values to be 100% sure.

Active cooling of the hot end: can't do

Purge tower in prusa with two different nozzles is not possible in prusa slicer options indeed. I could set up something in the tool change gcode section (i like the idea that it is embedded in the gcode and doesn't interfere with the purging and tool changes of the resurrect , start, etc... like printing 2 concentric circles in some place of the bed at every tool change. Shouldn't be to hard. Is it what you had in mind ?

Purge corner seems doable too, I'm not familiar with the technical solutions for this but will look into it.

Thank you for your help!

-

So I should have looked closer at the gcode before but it's actually quite messy so there could be this

Anyway I setup a wipe tower for both extruders. Created a 40mm wide, .4mm thick pipe, sliced it in the place i want the wiping to happen with the two extruders separately, extracted the gcode for 1 layer for each, deleting the G1 Zx.xx instructions, and created a macro called wipetower.g executed on every tool changes. In the macro depending on the tool selected it will extrude the corresponding circles (2 lines wide for .2mm nozzle and 1 for .4mm) at the designated place.

Will test and reportI also redesigned the cooling system that i was not really happy with, should be much better

I'll definitely look into having smoother walls for the organic support but I don't think we have much control over this...