Multiple Drivers for one stepper motor

-

Hey,

since there are many posts about how to control several motors with one driver, I am toying with the idea of whether it would also be possible the other way round. I realise that this question cannot arise if the control system is dimensioned correctly. In my case, however, I am trying to use the components I already have as much as possible.

I'm currently building a small desktop CNC mill that I'm running with a leftover Duet 3 Mini 5+. As the motor for the Z-axis is unfortunately a bit too weak, I would like to upgrade it.Now to my question: As I only operate 3 axes, two stepper drivers would still be free. Can I run two drivers in parallel to operate one motor with a higher rated current, e.g. a Nema 23 with 3.6A?

I know that this is certainly not ideal. However, considering the circumstances, it would be an efficient use of resources.Many thanks in advance!

-

@Pit96 I'd say almost certainly not. The pulses from the drivers are not going to synchronised to any degree and I dread to think what running two in parallel would do to the feedback mechanisms used by TMC drivers.

-

Hi @gloomyandy,

I was also afraid that it would mess up the feedback loop. I know that for AWD setups there is the possibility to assign two drivers for one axle. So at least the output signal should be identical? -

@Pit96 the outputs from stepper drivers are PWM. They wouldn't be in phase between two drivers even if they are fed with the same step and direction signals.

-

@Pit96 theres a method for "synchronizing" motors on a 4WD system here https://www.youtube.com/watch?v=so9oqJyirKY

-

@Pit96 I can't imagine how the "output signal" could be "identical". Both TMC drivers will be generating a PWM signal that is at a much higher frequency than any step information and since the drivers do not share a common clock (and are likely to me making different calculations based on feedback etc.), then I'd say there is no chance they will line up. In a AWD you have two motors driven by one driver each. The motor movement in that setup will be very similar and there is a nice "rubber band" between them to absorb any slight differences. But that is very different to connecting two drivers electrically together.

-

Ok guys, thanks a lot, I got it.

Then my next steps will be- Attach a counterweight/preload spring for the Z-axis

- Max out the stepper size for the TMC2209

- Install a gearbox if necessary

-

@Pit96 or add a 1XD, 1HCL, 3HC or another mainboard run in expansion board mode over CAN and run the bigger Z from that

-

@jay_s_uk This is of course also possible. However, as I believe that the weight of the Z-axis with spindle motor is primarily responsible for the lost steps, I rule this out for the time being with a counterweight. Then I will consider whether the motor dimensions are at all practicable.

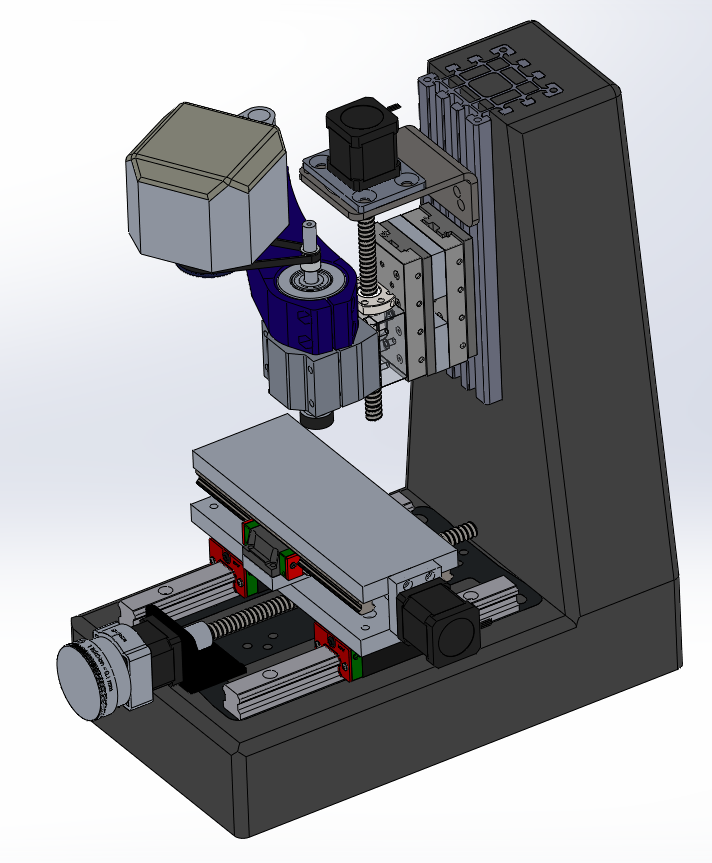

Here is a photo of the CAD model to give you an idea. Yesterday I made the first chips in Styropr with the real milling machine.